Method for preparing ammonium fluorosilicate and coproducing white carbon black from fluorine-containing tail gases of phosphoric acid device

A technology of ammonium fluorosilicate and fluorosilicic acid, applied in the field of phosphorus chemical industry, can solve the problems of difficult waste disposal, low added value of products, low utilization rate of fluorine resources, etc., to reduce pollution, avoid chemical balance deviation, and ensure fluorine recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

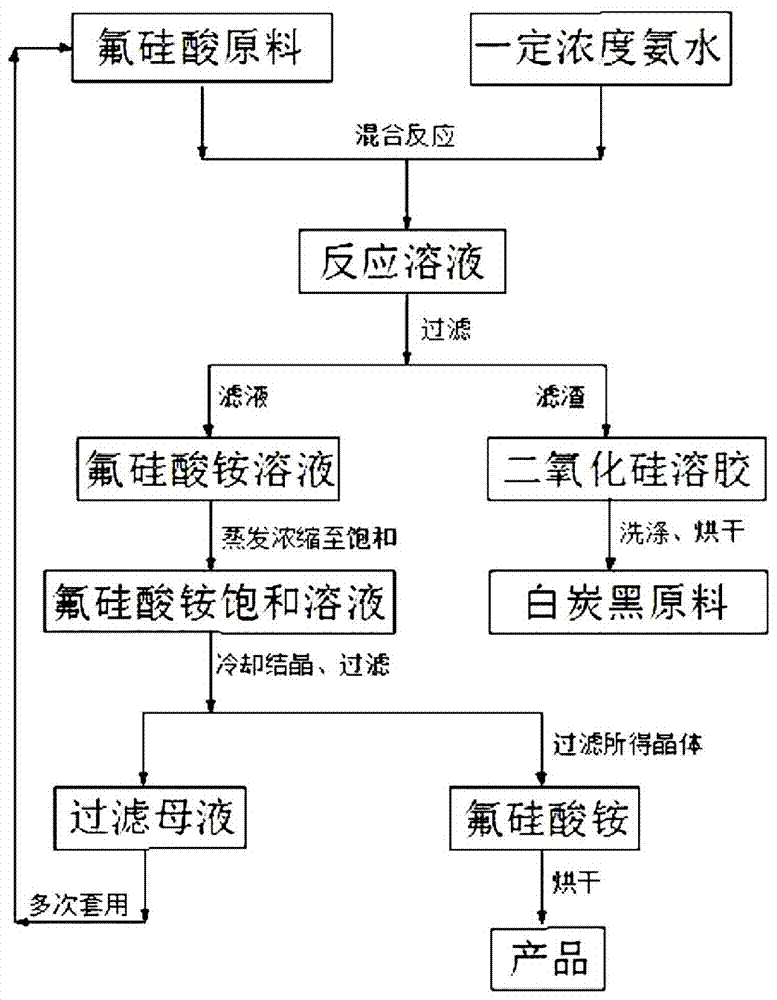

[0034] The method for preparing ammonium fluorosilicate and co-producing white carbon black by utilizing fluorine-containing tail gas of a phosphoric acid plant comprises the following steps:

[0035] 1) Absorb the fluorine-containing tail gas with a phosphoric acid device with water to obtain a solution with a concentration of fluorosilicic acid above 10%; then add 10 wt% ammonia water for neutralization, stop adding ammonia water until the pH of the solution is 2, continue stirring for 20 minutes, and then discharge;

[0036] 2) The feed liquid obtained in step 1) is separated and filtered with a membrane filter press, the temperature of the feed liquid during the filtration process is controlled at 60-80° C., the filter residue is washed and dried to prepare white carbon black, and the filtrate is used for later use;

[0037] 3) The filtrate is evaporated and concentrated to a specific gravity of 1.2, then cooled, crystallized below 15°C, and finally filtered, and the obtain...

Embodiment 2

[0040] The method for preparing ammonium fluorosilicate and co-producing white carbon black by utilizing fluorine-containing tail gas of a phosphoric acid plant comprises the following steps:

[0041] 1) Use the mother liquor after ammonium fluorosilicate crystallization and filtration to absorb fluorine-containing tail gas from a phosphoric acid plant to obtain a solution with a concentration of 15% fluorosilicic acid; then add 10 wt% ammonia water for neutralization, and stop adding ammonia water until the pH of the solution is 2. Continue to stir for 20 minutes and discharge;

[0042] 2) The feed liquid obtained in step 1) is separated and filtered with a membrane filter press, the temperature of the feed liquid during the filtration process is controlled at 60-80° C., the filter residue is washed and dried to prepare white carbon black, and the filtrate is used for later use;

[0043] 3) The filtrate is evaporated and concentrated to a specific gravity of 1.21, then cooled...

Embodiment 3

[0046] The method for preparing ammonium fluorosilicate and co-producing white carbon black by utilizing fluorine-containing tail gas of a phosphoric acid plant comprises the following steps:

[0047] 1) Use the mother liquor after ammonium fluorosilicate crystallization and filtration to absorb fluorine-containing tail gas from a phosphoric acid plant to obtain a solution with a concentration of 13% fluorosilicic acid; then add 15 wt% ammonia water for neutralization, and stop adding ammonia water until the pH of the solution is 3. Continue to stir for 25 minutes before discharging; 2) The feed liquid obtained in step 1) is separated and filtered with a diaphragm filter press, the temperature of the feed liquid during the filtration process is controlled at 70-80°C, and the filter residue is washed and dried to prepare white carbon black , the filtrate is standby;

[0048] 3) The filtrate is evaporated and concentrated to a specific gravity of 1.21, then cooled, crystallized be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com