Bearing roller feeding mechanism and bearing roller feeding equipment

A bearing roller and roller technology, applied in the field of bearing roller feeding mechanism and bearing roller feeding equipment, can solve the problems of inconvenient transportation, reduced productivity, bearing roller damage, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

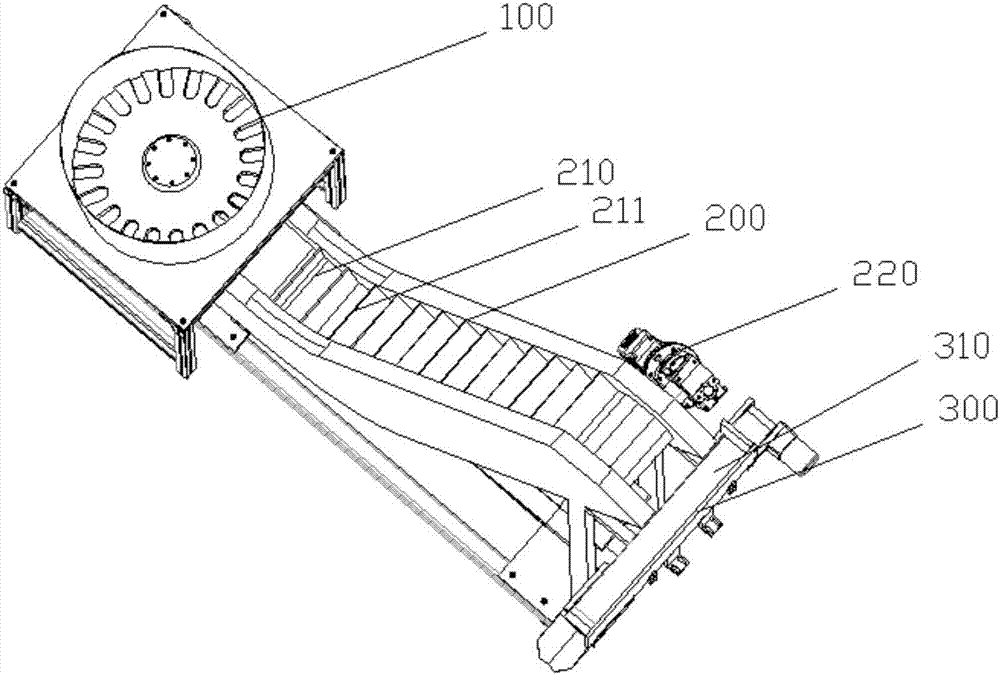

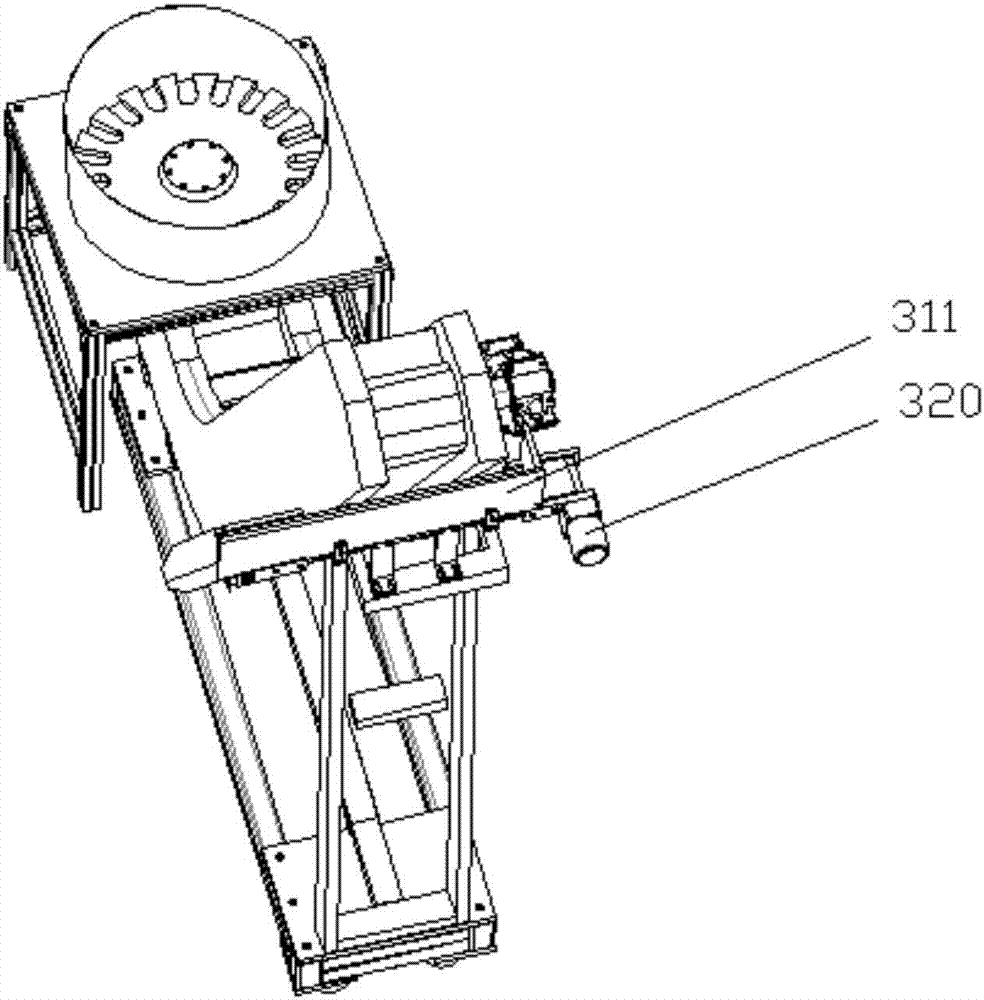

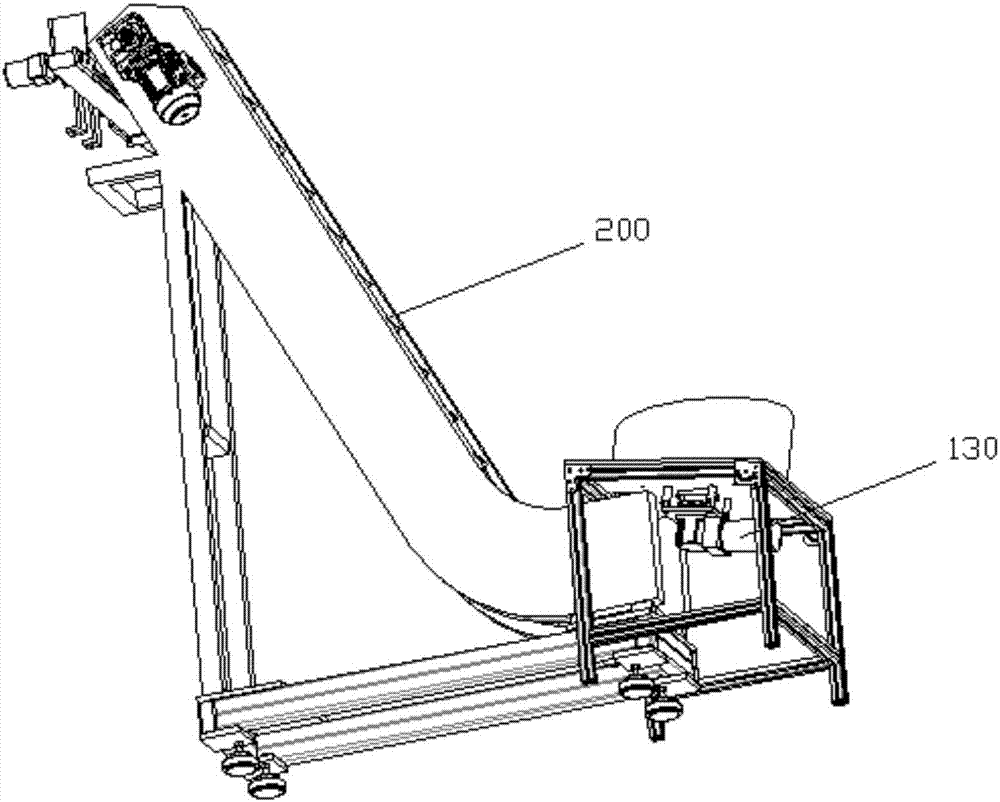

[0045] Such as figure 1As shown in -4, a bearing roller feeding mechanism provided in this embodiment includes a roller storage conveying assembly 100, a roller climbing conveying assembly 200 and a roller plane conveying assembly 300; the roller discharging conveying A discharge port 121 is provided at the bottom of the assembly, and the roller climbing conveyor assembly 200 is arranged in the next process of the roller storage conveyor assembly 100, and the discharge port 121 is connected with the roller climbing conveyor assembly 200 corresponding to the input end; the roller plane conveying assembly 300 is arranged in the next process of the roller climbing conveying assembly 200, and the discharge end of the roller climbing conveying assembly 200 is connected with the roller The feeding end of the sub-plane conveying assembly 300 is arranged correspondingly; the conveying direction of the roller plane conveying assembly 300 is set horizontally, and the conveying direction...

Embodiment 2

[0062] On the basis of Embodiment 1, this embodiment provides a bearing roller feeding device, which includes the bearing roller feeding mechanism.

[0063] The beneficial effect of this embodiment:

[0064] A bearing roller feeding device provided in this embodiment includes the bearing roller feeding mechanism, so the technical advantages and effects achieved by the bearing roller feeding device include the above bearing roller feeding mechanism The technical advantages and effects achieved will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com