Cargo grabbing device for industrial robot

An industrial robot and grabbing device technology, which is applied in the field of cargo grabbing devices, can solve the problems of easy falling of goods and unstable grabbing of goods, and achieve the effects of improved safety performance, good stability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

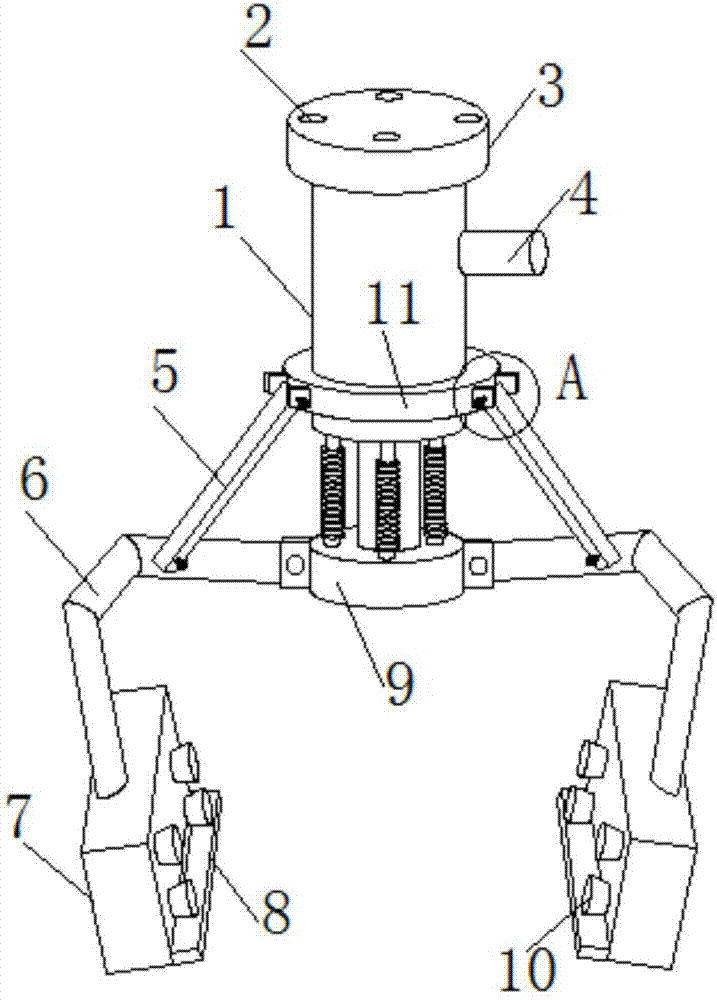

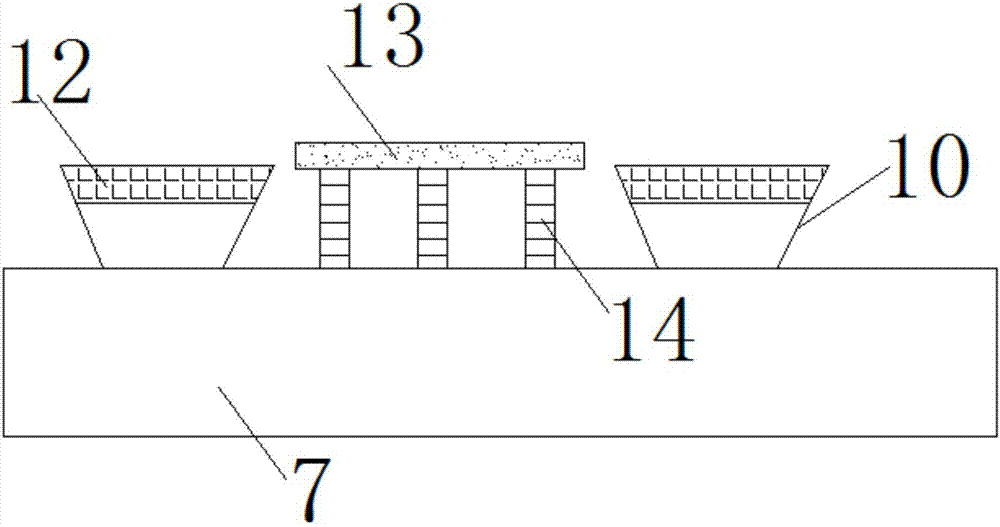

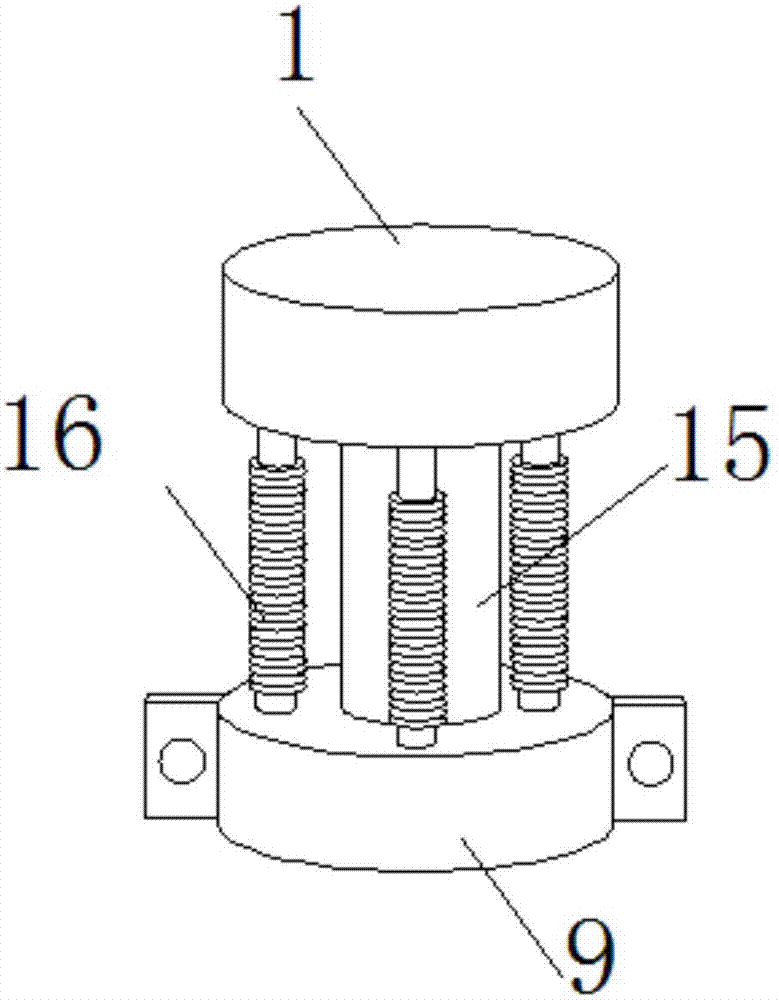

[0025] see Figure 1-5 As shown, a cargo grabbing device for an industrial robot includes a hydraulic column 1, a support rod 5, a mechanical arm 6 and a baffle 7. A connecting pipe 4 is connected to one side of the middle of the hydraulic column 1, and the bottom end of the hydraulic column 1 A collar 11 is welded on the outside, and three sets of support rods 5 are evenly connected to the outside of the collar 11. The collar 11 facilitates the flexible connection between the support rod 5 and the hydraulic column 1 through the protrusion 20 and the fastening bolt 19, and the other end of the support rod 5 is connected through a tight The fixed bolt 19 is movably connected to the mechanical arm 6, which is convenient to drive the mechanical arm 6 to move during work. The bottom of the hydraulic column 1 is movably connected to the telescopic rod 15. The bottom of the telescopic rod 15 is connected to the fixed head 9, and the outside of the fixed head 9 is evenly connected to ...

Embodiment 2

[0027] Additionally, according to Figure 1-5 As shown, the difference between it and the above embodiment is that: the top of the hydraulic column 1 is welded with a mounting head 3, and there are several bolt holes 2 inside the mounting head 3, and the hydraulic column 1 is conveniently connected with the industrial robot through the mounting head 3 and the bolt holes 2. The moving arm is connected, and the grabbing device can move freely during work. Two groups of protruding heads 20 are provided at the connection between the collar 11 and the fixed head 9 and the supporting rod 5 and the mechanical arm 6, and one end of the supporting rod 5 and the mechanical arm 6 is inserted between the two protruding heads 20, and the supporting rod 5 and the mechanical arm 6 are inserted between the two protruding heads 20. The arm 6 is movably connected with the collar 11 and the fixed head 9 respectively through the protruding head 20 and the fastening bolt 19, so that the mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com