Shot blasting machine

A shot blasting machine and shot blasting machine technology, which is applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problem of the reduction of the scope of application of the shot blasting machine, and achieve the effects of simple structure, convenient operation and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

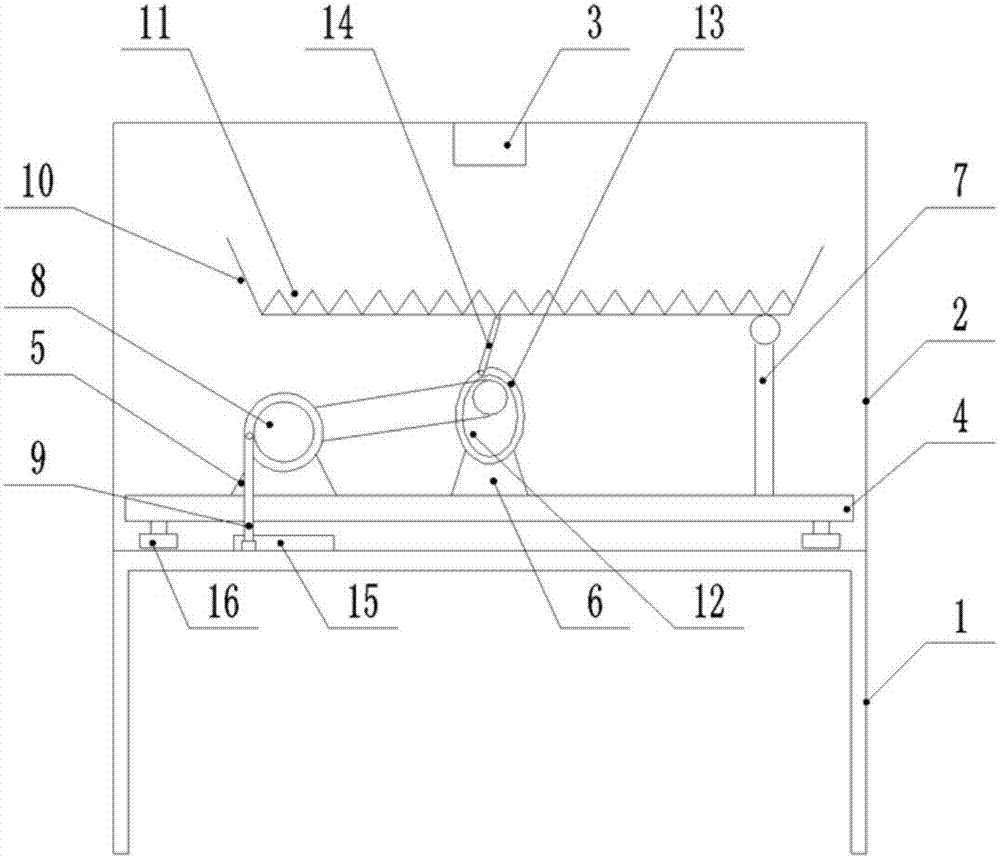

[0020] Such as figure 1 As shown, the shot blasting machine includes a machine base 1, the upper surface of the machine base 1 is welded with a box body 2, and the top of the box body 2 is connected with a shot blasting device 3 through bolts, and the shot blasting machine 3 is located in the middle of the top of the box body 2 , the lower surface of the bottom plate 4 is equipped with a pulley; the left end of the bottom plate 4 is connected with a servo motor 5 by bolts, the middle of the bottom plate 4 is connected with a support seat 6 by bolts, and a cam 12 with a pulley is installed on the support seat 6, and the cam 12 is along the circumference A chute 13 is provided in the direction, and one end of the guide rod 14 is connected with the chute 13 through a runner, and the other end is fixedly connected with the middle position at the bottom of the tray 10, and the upper surface of the tray 10 has evenly distributed V-shaped grooves 11; The right end of the bottom plate...

Embodiment 2

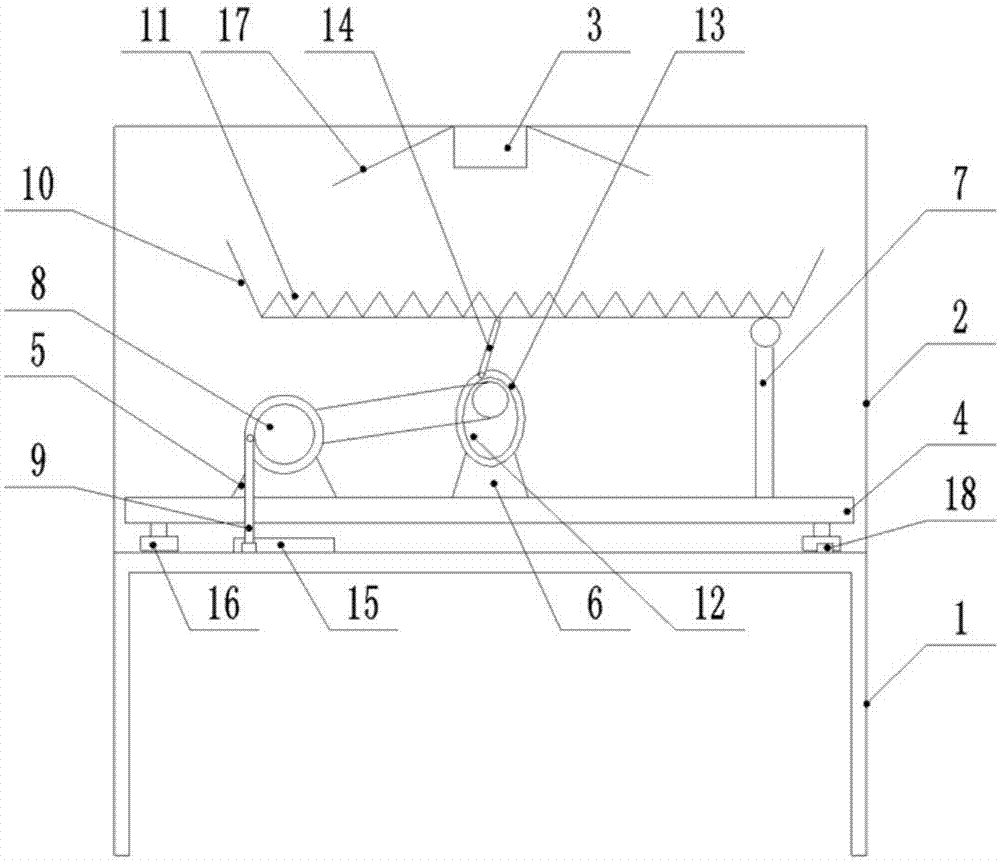

[0023] Such as figure 2 As shown, on the basis of Embodiment 1, inclined baffles 17 are welded on both sides of the blasting device 3, so that the blasting device 3 only blasts the part of the tray 10 to improve the blasting efficiency; The bottom of the groove 11 is provided with a waste chip discharge through hole, which is convenient for the waste chips generated during shot blasting to be discharged through the through hole in time to prevent the waste chips from accumulating in the V-shaped groove 11 and affecting the shot blasting of the parts; before and after the machine base 1 Weld stoppers 18 at both ends to prevent the base plate 4 from slipping out from the slide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com