Automatic circulation type rolling and polishing machine and working method thereof

A cyclic, working cavity technology, applied in chemical instruments and methods, surface-polished machine tools, manufacturing tools, etc., can solve problems such as affecting product production efficiency, consuming a lot of time and manpower, and insufficient product processing, saving personnel. The effect of input cost, improved utilization efficiency, and easy reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The embodiments of the present invention will be described in detail below. Examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals indicate the same or similar elements or elements with the same or similar functions. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention, but should not be construed as limiting the present invention.

[0040] In the description of the present invention, it should be understood that the terms "center", "longitudinal", "transverse", "length", "width", "thickness", "upper", "lower", "front", " The orientation or positional relationship indicated by “rear”, “left”, “right”, “vertical”, “horizontal”, “top”, “bottom”, “inner”, “clockwise”, and “counterclockwise” are based on the attached The orientation or positional relationship shown in the figure is only for the convenience of describing the present...

Embodiment 2

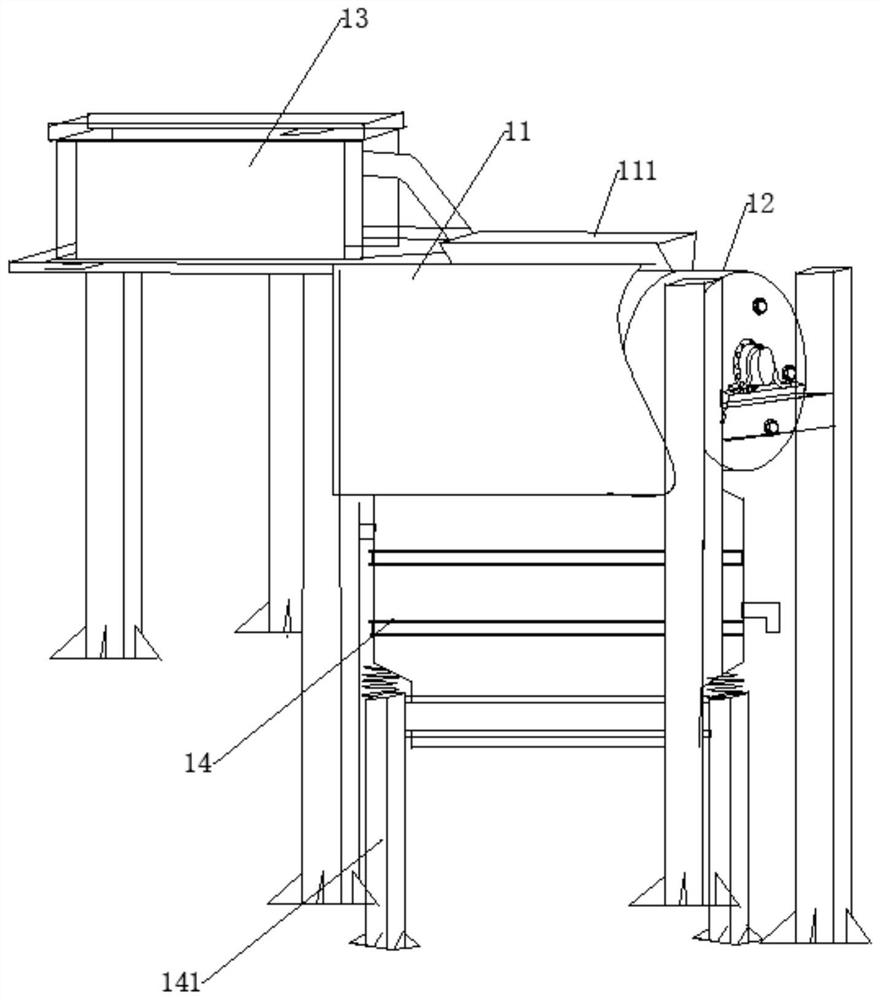

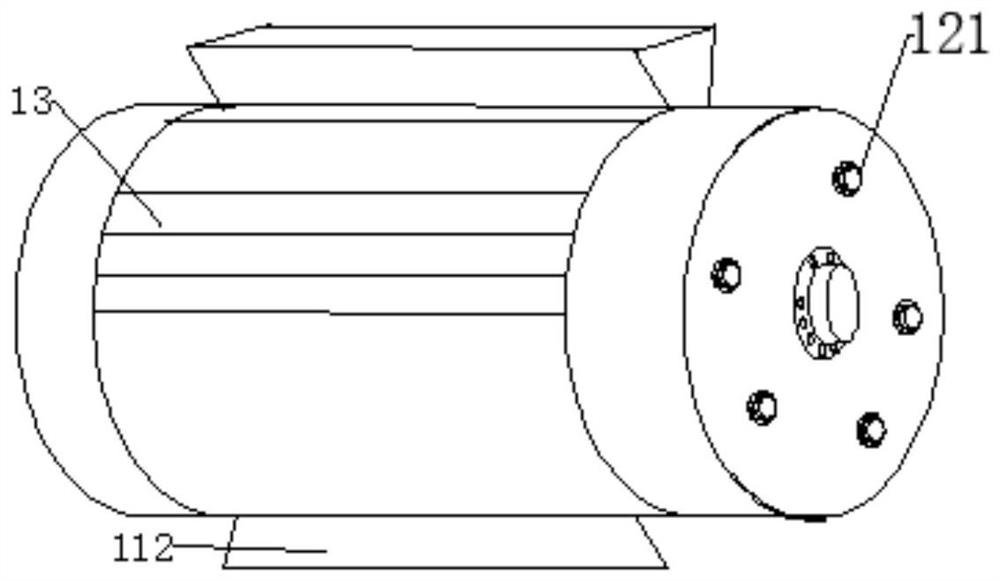

[0054] As shown in the figure, an automated circulating tumbler and polisher includes: a housing 11, a drum 12, a shot blasting feeding mechanism 13 and a material distributing mechanism 14, wherein the drum 12 is provided with a plurality of working chambers 121, so The casing 11 is provided with a feed inlet 111 and a discharge port 112, the drum 12 is arranged inside the casing 11, the shot blasting feeding mechanism 13 is connected to the drum 12 through a feeding pipe, and the distributing mechanism 14 Located below the drum 12, the distribution mechanism 14 is provided with a shot blasting recovery box 1401, and the shot blasting recovery box 1401 is connected to the shot blasting feeding mechanism 13 through a return pipe.

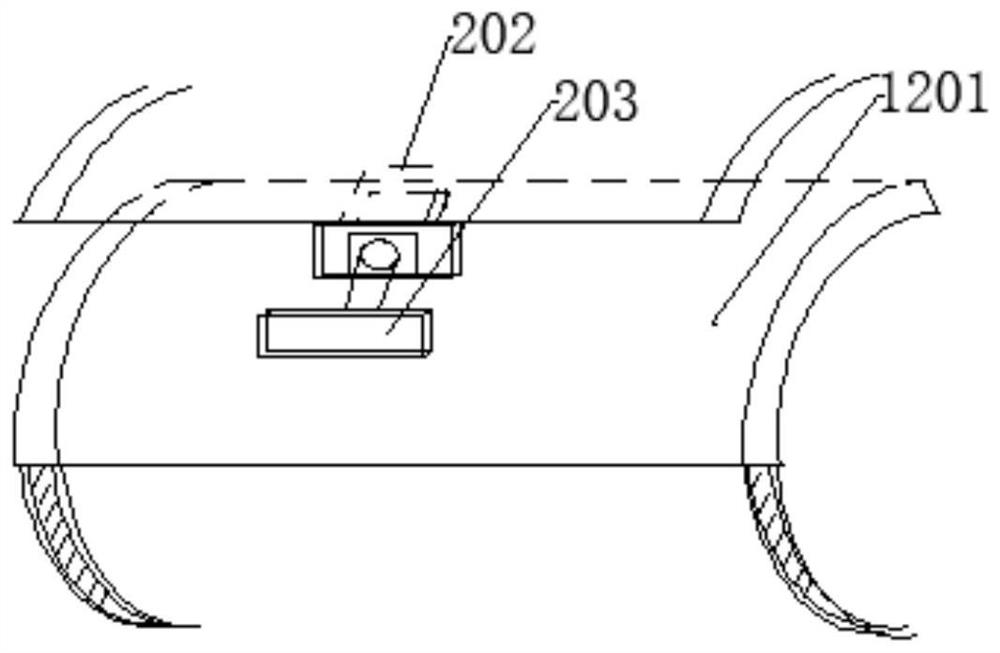

[0055] In this embodiment, the working cavity 121 is provided with a main working cavity and a driven working cavity, the main working cavity and the driven working cavity are both provided with a sealing plate 1201, and the main working cavity and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com