A positioning guide device and processing method for step deep hole processing

A positioning guide, step hole technology, used in metal processing equipment, positioning measurement in boring/drilling machines, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

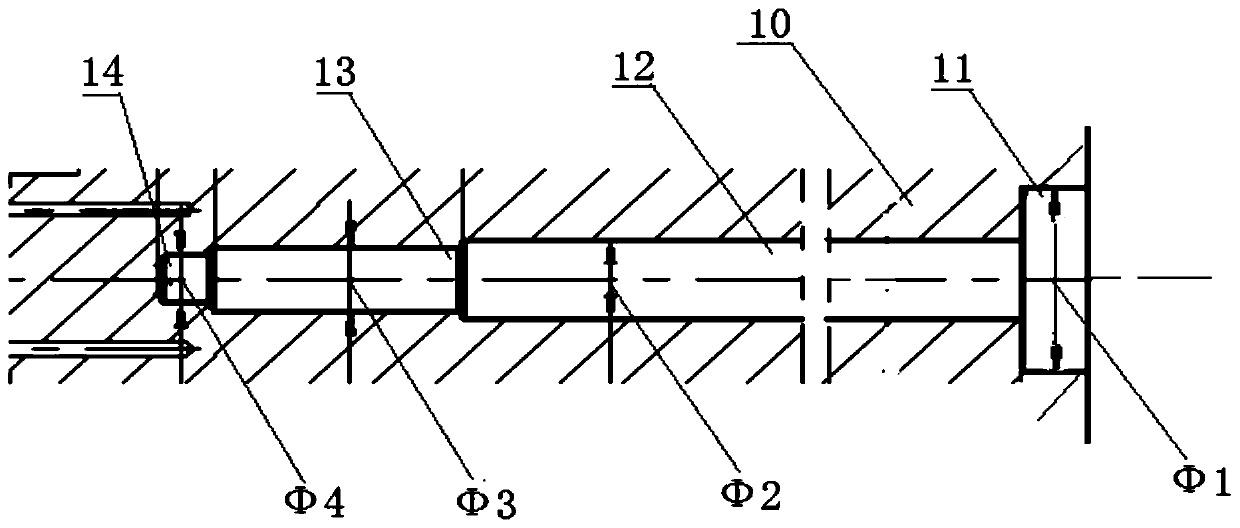

[0055] Embodiment: A workpiece needs to process the deep hole of the step to be a four-step deep hole, see figure 1 ; Except for the first-level holes, the rest are deep holes, and each level of step deep holes requires a roughness of Ra1.6, and no borrowing marks are allowed.

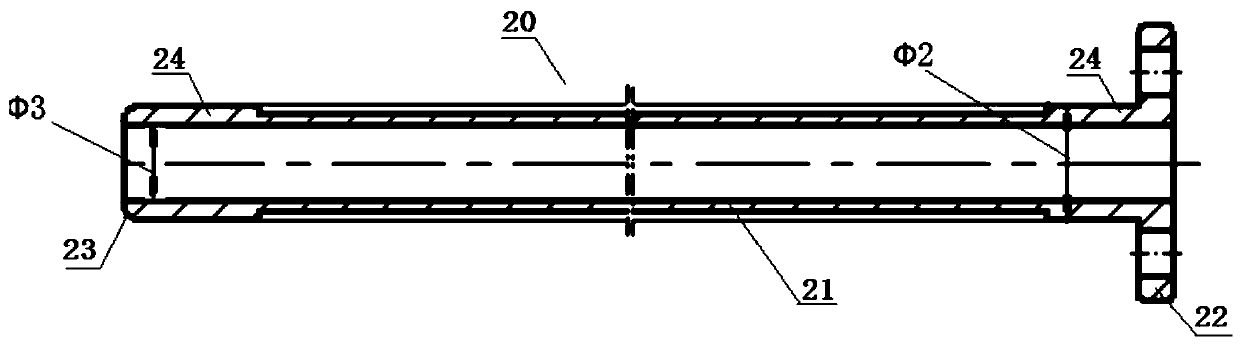

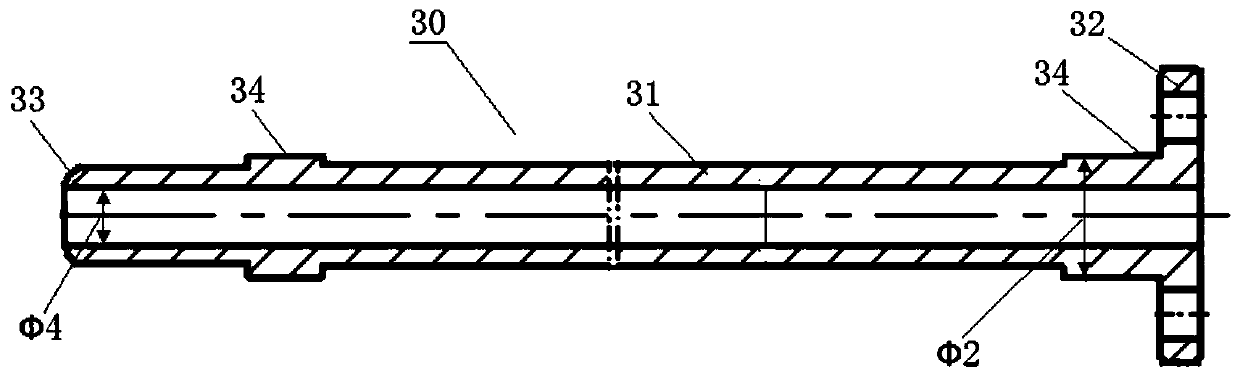

[0056] The processing steps are as follows: (see figure 1 , figure 2 with image 3 )

[0057] The first step is to process the first-level step hole, the second-level step hole and the process screw hole; firstly process the first-level step hole 11 and the second-level step hole 12 with a diameter of 25 mm (millimeters) on the workpiece with a gun drill, and in the first-level The edge of the step orifice is processed with multiple process screw holes; the first step hole, the second step hole and the process screw hole do not need to use the step positioning guide member;

[0058] The second step is to install the secondary step positioning guide member; see figure 2 with image 3 , put the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com