Bird repelling equipment for power grid equipment

A power grid equipment and bird repelling technology, applied in the power grid field, can solve the problems of increasing impeller friction, active dust adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

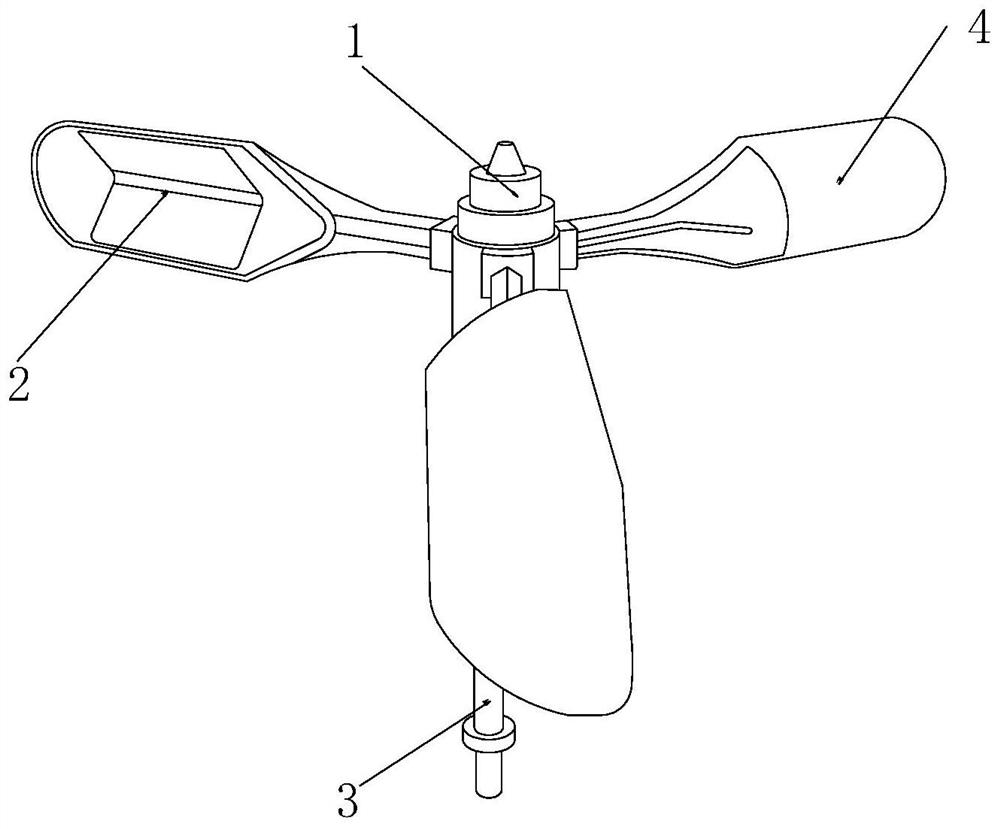

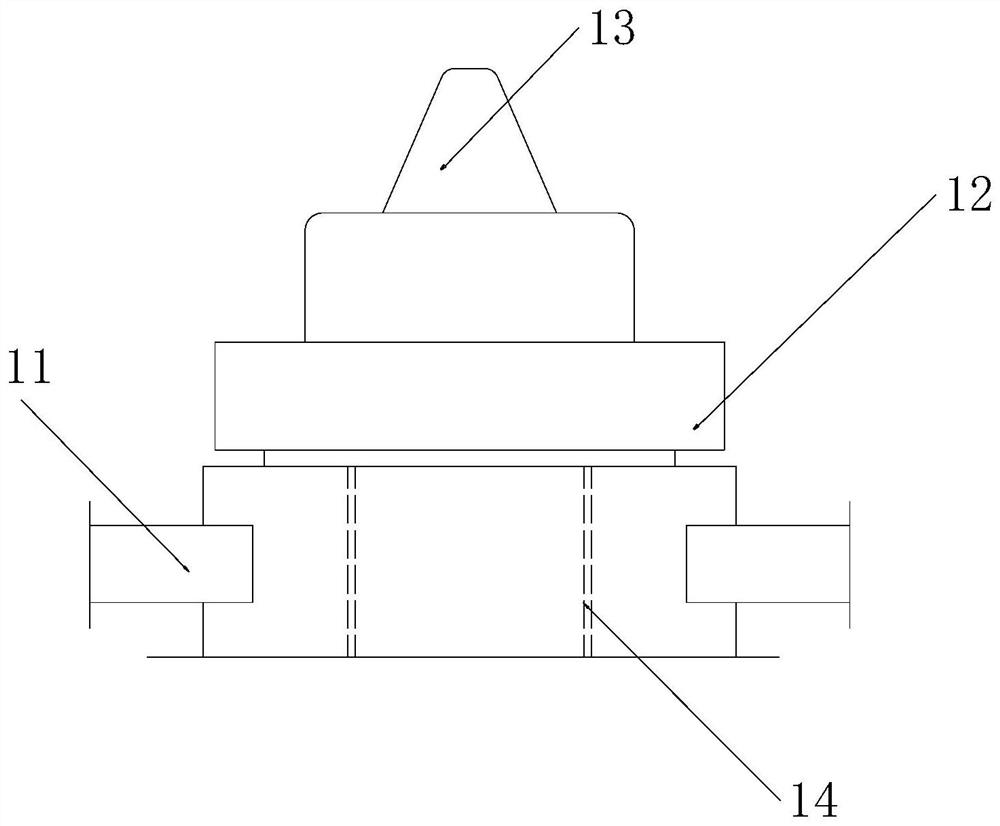

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides a bird repelling device for power grid equipment, the structure of which includes an inlay shaft 1, a reflector 2, a connecting rod 3, and a blade 4, the inlay shaft 1 is inlaid directly above the connecting rod 3, and the reflector 2. Embedded on the inner end surface of the blade 4, the connecting rod 3 is embedded and installed directly below the blade 4, and the blade 4 is evenly arranged on the outer surface of the lower end of the embedded shaft 1; the embedded shaft 1 includes an embedded Strip 11, masking mechanism 12, pointed cone block 13, inlaying groove 14, the embedding solid bar 11 is embedded and installed on the outer end surface of the inlaying groove 14, and the covering mechanism 12 is nested and engaged on the inner upper end surface of the inlaying groove 14 The pointed cone block 13 is inlaid directly above the masking mechanism 12 , and the inlay groove 14 is located...

Embodiment 2

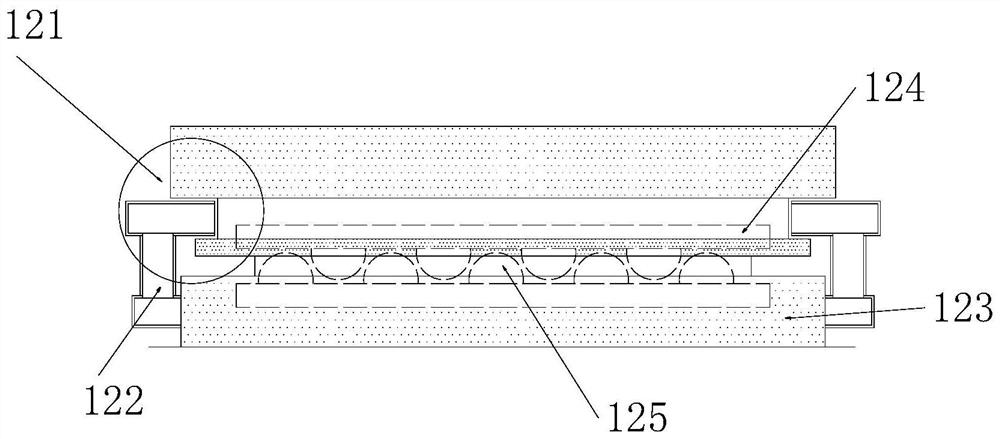

[0033] as attached Image 6 to attach Figure 7 Shown:

[0034]Wherein, the vibration mechanism 123 includes a rotating rod 231, an impact mechanism 232, a bevel block 233, and a third inlay groove 234. The rotating rod 231 is fixedly installed directly above the third inlay groove 234, and the impact mechanism 232 is evenly Set on the outer upper end surface of the third embedding groove 234, the inclined plane block 233 is embedded on the inner upper end surface of the vibration mechanism 123, the third embedding groove 234 is located directly below the inclined plane block 233, and the right side of the inclined plane block 233 The side end surface is inclined, and the impact mechanism 232 can be pushed to bend to the left by the counterclockwise rotation of the vibration mechanism 123 .

[0035] Wherein, the impact mechanism 232 includes a hollow ball 321, a magnetic block 322, an impact ball 323, a hollow fixed tube 324, and a rubber strip 325. The hollow ball 321 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com