A safe and reliable bending machine

A bending machine and reliable technology, applied in the field of bending machines, can solve the problems of destroying the accuracy of sheet processing, reducing the qualified rate of workpiece processing, sheet displacement, etc., so as to achieve firm and reliable clamping work, improve the qualification rate, and ensure clamping effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

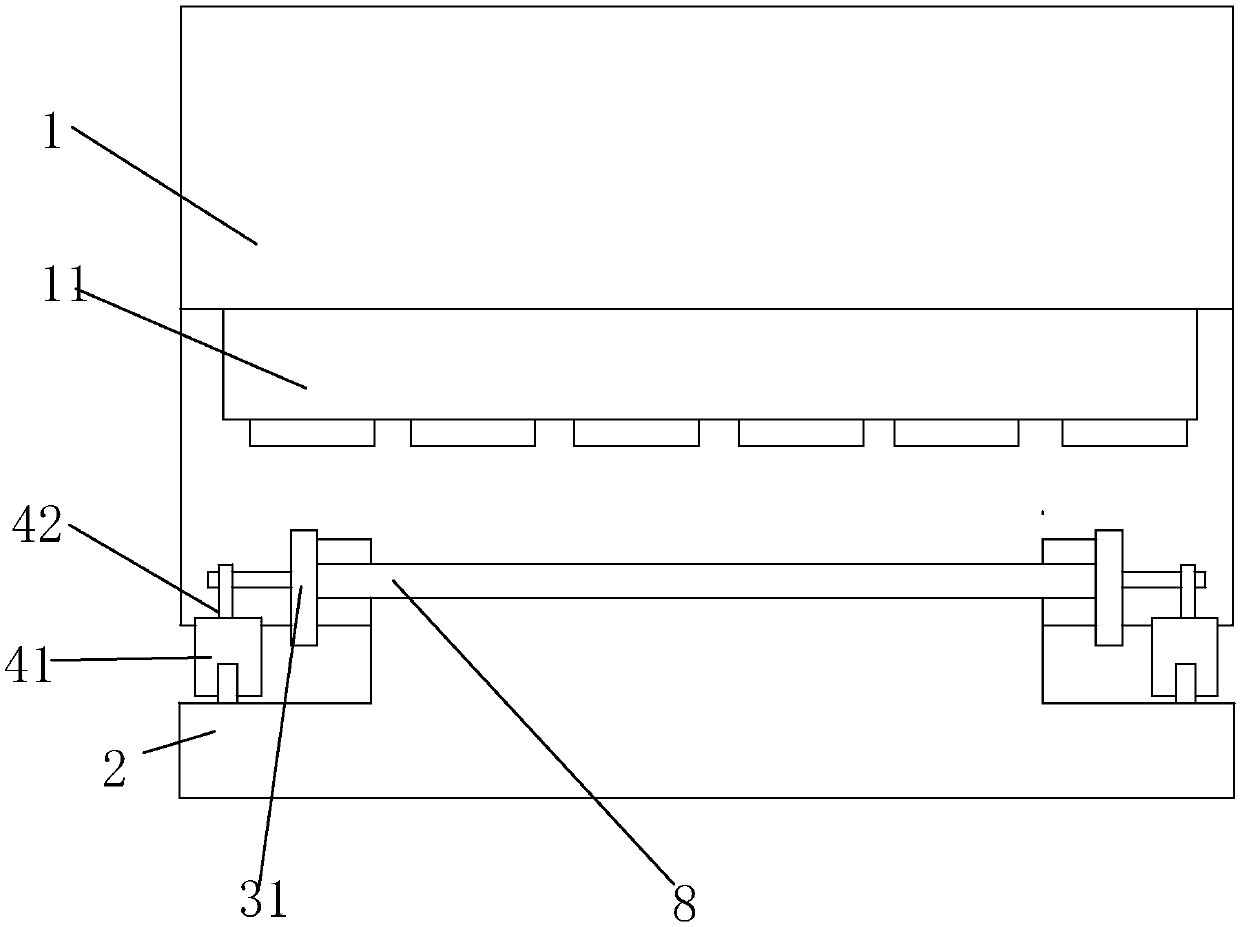

[0022] Embodiment: A safe and reliable bending machine, including a machine body 1, a bending work area 11 arranged on the machine body 1, and a power source (not shown in the figure) that controls the bending work area 11 for bending processing. The part of the workpiece 8 to be bent is placed in the bending work area 11 , and the power source controls the work of the bending work area 11 to realize the bending process of the workpiece 8 .

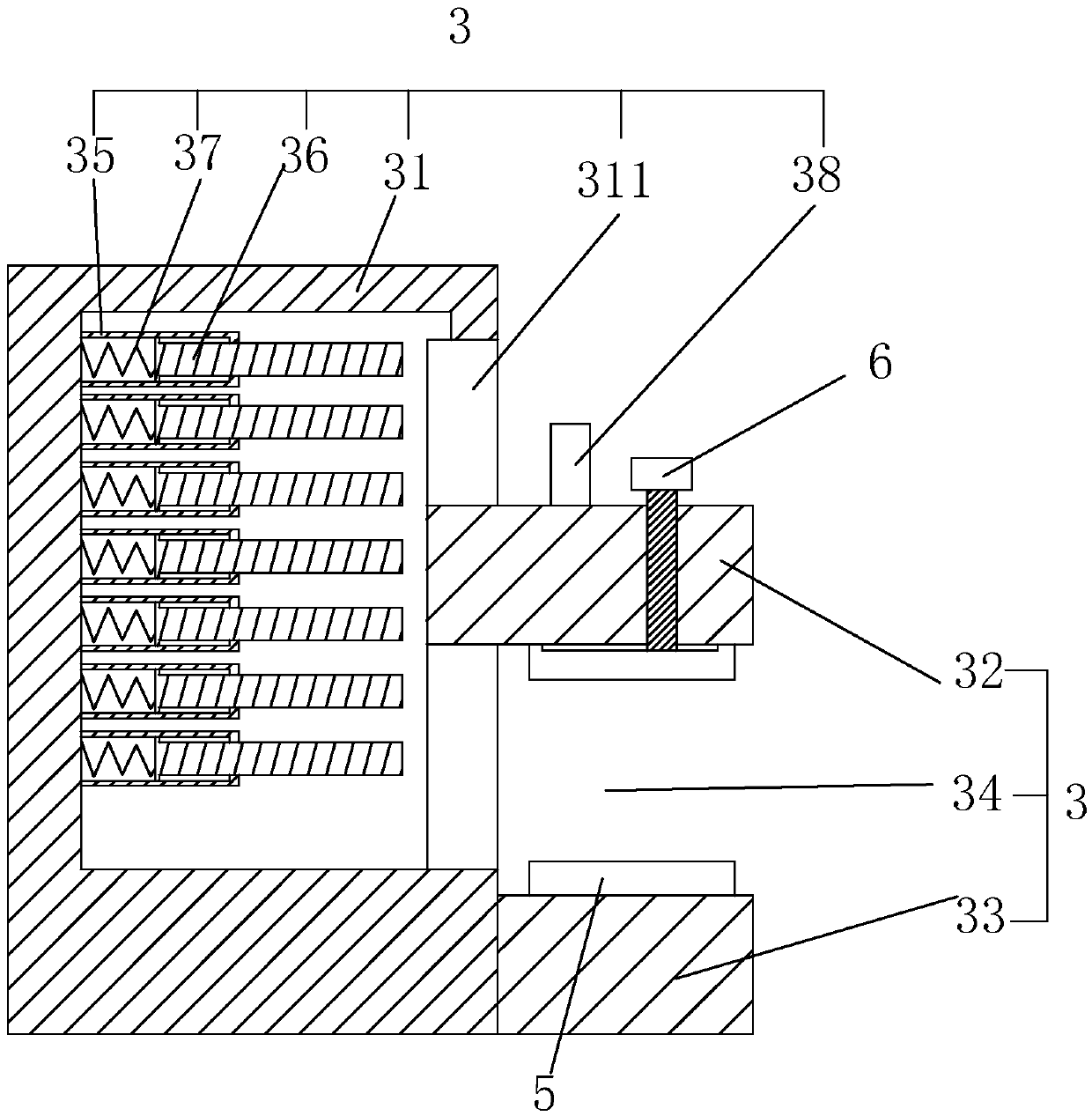

[0023] At this time, a workbench 2 for placing the workpiece 8 is provided on the body 1 close to the bending work area 11. A pair of clamping devices 3 for clamping the workpiece 8 are symmetrically provided at both ends of the workbench 2. The clamping device 3 It includes a connecting plate 31 arranged at one end of the workbench 2, a lower splint 33 and an upper splint 32 are provided on the side of the connecting plate 31 close to the workbench 2, and a working space for inserting the workpiece 8 is formed between the upper splint 32 ...

specific Embodiment approach

[0026] Specific implementation method: Place the sheet workpiece 8 on the workbench 2, and insert the two ends of the workpiece 8 into the working groove 34 of the clamping device 3, so that the workpiece 8 is in conflict with the lower splint 33, and then slide the upper splint 32, to make it slide near the workpiece 8, and conflict with the sheet workpiece 8, and then control the electromagnet 38 to be energized. The upper surface of the upper clamping plate 32 is in contact, so as to realize the impact on the upper clamping plate 32, so that the upper clamping plate 32 is fixed at this position.

[0027] At this time, the clamping work of the upper splint 32 and the lower splint 33 to the sheet workpiece 8 is ensured. During the bending process of the workpiece 8, the hydraulic cylinder 41 works at the same time, and the telescopic movement of the piston rod 42 can drive the clamping device. 3's lifting work, it can also drive the lifting of the sheet workpiece 8, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com