Silicon steel production planning system

A technology for production planning and silicon steel, applied in computing, instrumentation, data processing applications, etc., can solve the problems of non-silicon steel making-continuous casting production planning and design, complex operation of the production planning system, long production cycle of silicon steel, etc., so as to optimize silicon steel production mode, enhance market competitiveness, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

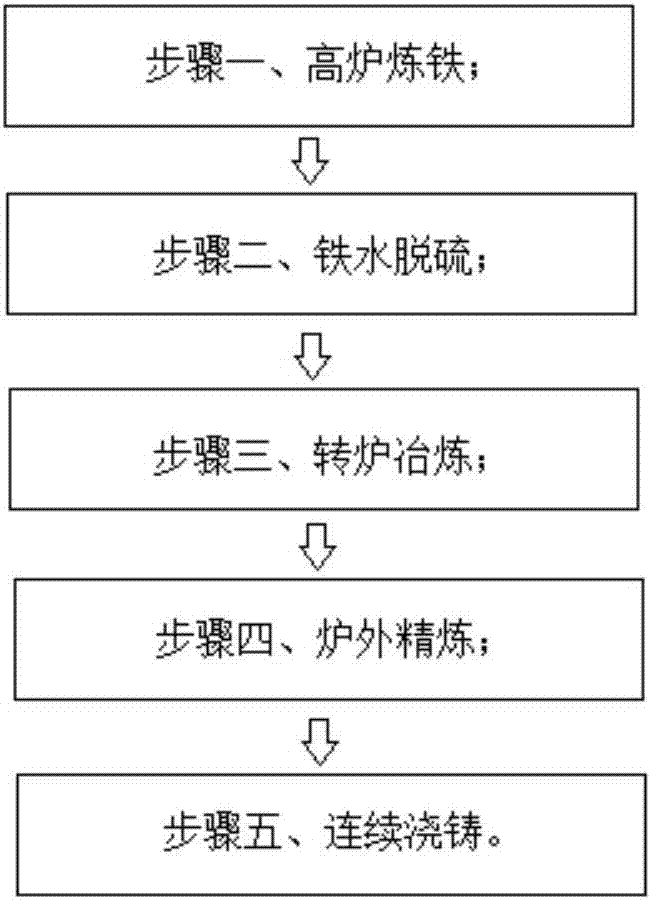

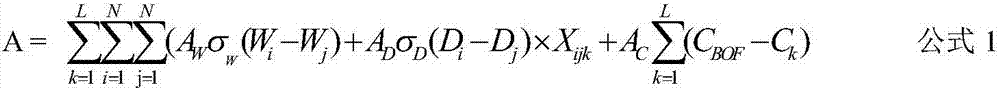

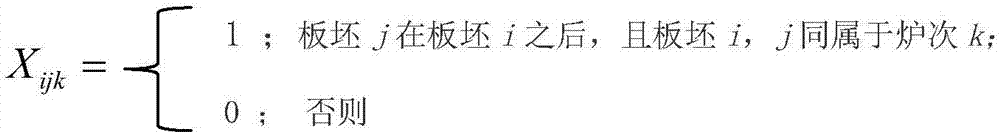

[0074] combine figure 1 , the silicon steel production planning system of the present embodiment produces silicon steel according to the following steps: step one, blast furnace ironmaking; step two, molten iron desulfurization, in step two, the sulfur content in molten iron is reduced to below 0.005% wt; For smelting, the top-bottom composite blowing is adopted in step 3, so that the carbon content is reduced to below 0.06%wt; step 4, refining outside the furnace, vacuum treatment is adopted in step 4, and the carbon content is reduced to below 0.01%wt; step 5, continuous casting. Among them: the following conditions are met in the process of controlling silicon steel making and continuous casting:

[0075]

[0076] in,

[0077] k: Converter heat schedule number, k∈{1,2...L};

[0078] L: the total number of converter heats;

[0079] i: the i-th slab;

[0080] j: the jth slab;

[0081] N: total number of slabs;

[0082] A W : Standard deviation correction coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com