Slot wedge machining and positioning device and using method thereof

A positioning device and slot wedge technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as low production efficiency, inability to realize automatic slot wedge processing, etc. The effect of convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

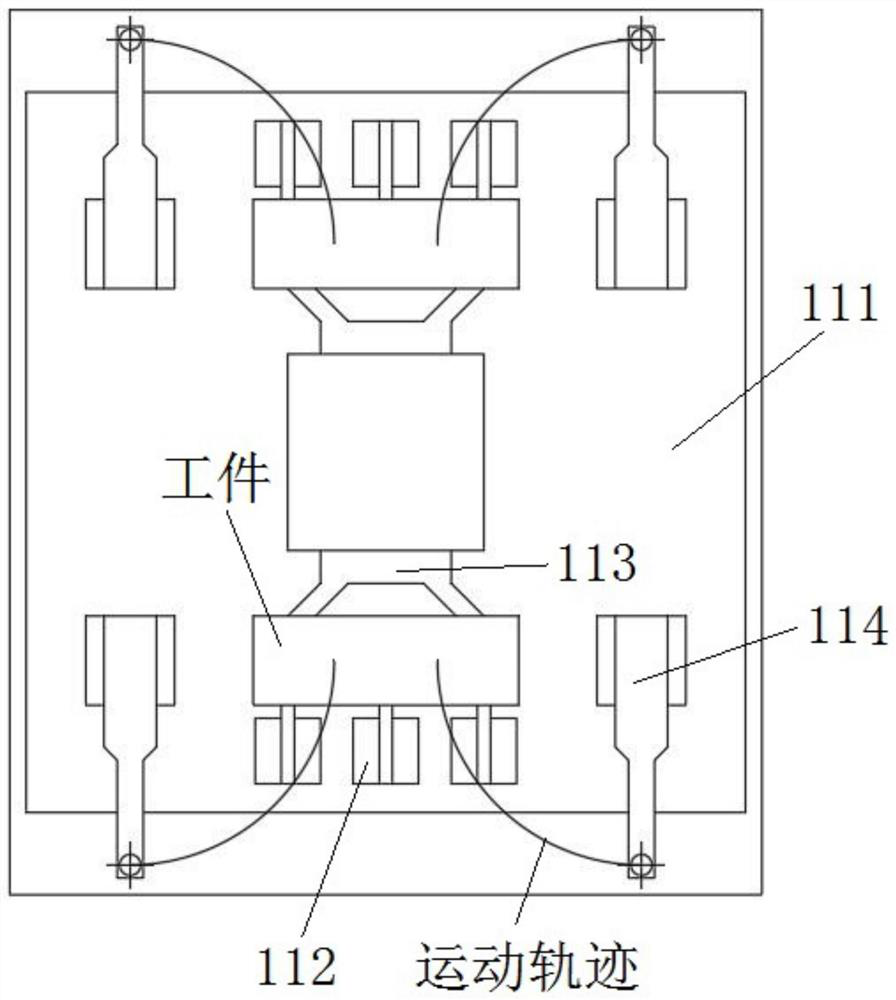

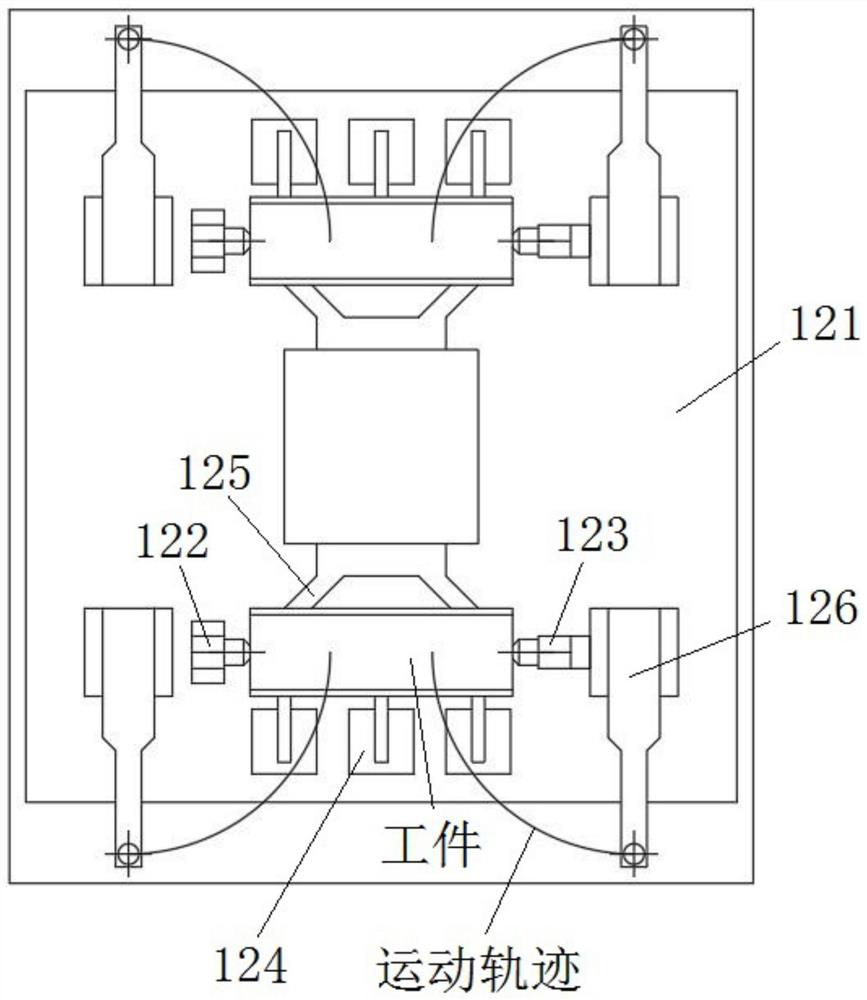

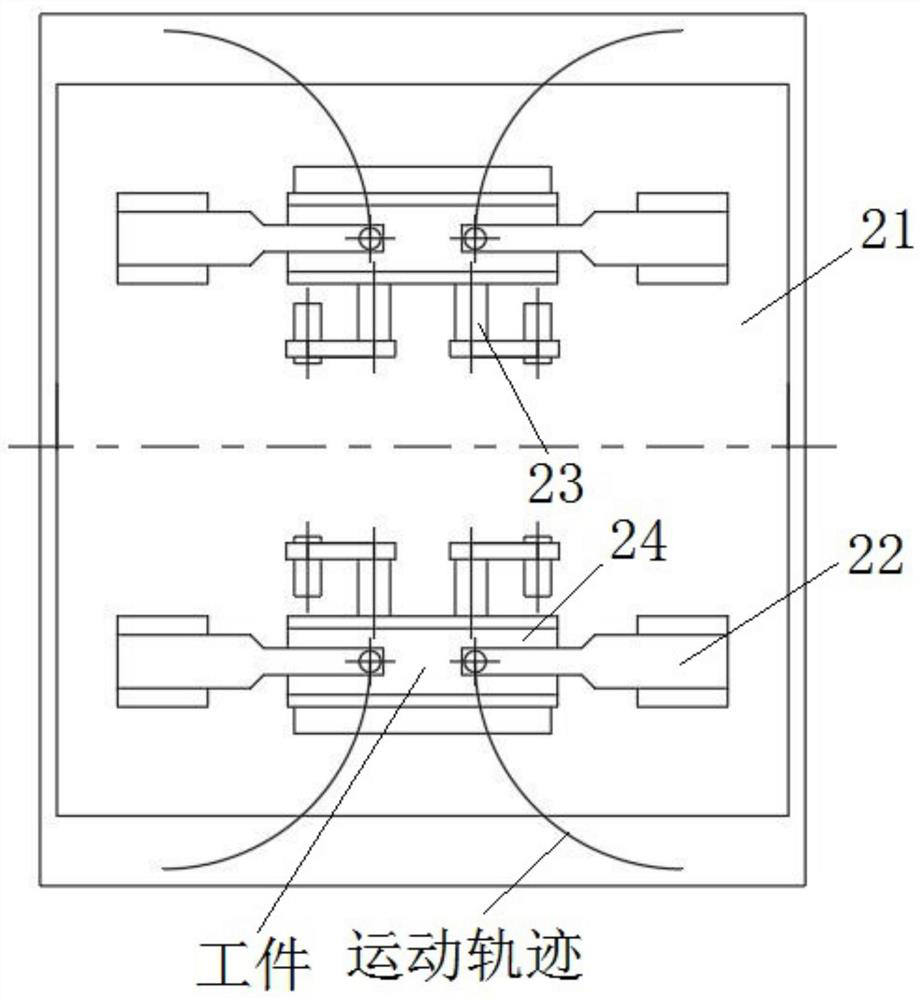

[0046] Such as Figure 1 to Figure 5 As shown, a positioning device for slot wedge processing includes a milling sequence positioning fixture 1 for positioning the slot wedge during profile milling, and a milling sequence positioning fixture 2 for positioning the slot wedge during profile milling.

[0047] Using the milling profile sequence positioning fixture 1 and the matching milling sequence positioning fixture 2, in conjunction with their respective machining centers, in a slot wedge processing positioning device of the present invention, it is possible to complete the full sequence of milling the profile of the slot wedge (that is, the workpiece to be processed). Slot wedge processing for machining and matching milling. In this way, the full-sequence automatic processing of slot wedges is realized, and the full-sequence slot wedge processing positioning and automatic clamping actions that meet the requirements of automatic loading and unloading are realized. The existing...

Embodiment 2

[0061] Such as Figure 1 to Figure 5 As shown, as a further optimization of Embodiment 1, this embodiment includes all the technical features of Embodiment 1. In addition, this embodiment also includes the following technical features:

[0062] A method for using the slot wedge processing and positioning device includes the following steps:

[0063] S1, using the milling profile sequence positioning fixture 1 to perform milling profile processing and positioning of the slot wedge;

[0064] S2, using the matching milling sequence positioning fixture 2 to position the slot wedge during the matching milling process.

[0065] Utilizing the milling profile sequence positioning fixture 1 and the matching milling sequence positioning fixture 2, and cooperating with their respective machining centers, in a slot wedge processing positioning device of the present invention, it is possible to complete the process of milling profile processing and matching milling processing for the slot...

Embodiment 3

[0070] Such as Figure 1 to Figure 5 As shown, this embodiment includes all the technical features of Embodiment 1 and Embodiment 2. On the basis of Embodiment 1 and Embodiment 2, this embodiment provides a more detailed implementation mode.

[0071] A positioning device for slot wedge processing, comprising: 1 set of positioning jig for milling shape sequence (including two positive and negative stations), 1 set of positioning jig for milling and bending hole sequence, and 1 set of positioning jig for matching milling sequence, a set consisting of 3 sets of jigs in total Group automatic positioning device system. Among them, 3 sets of automatic fixtures correspond to 3 machining centers respectively and are used together.

[0072] Positioning fixture for contour milling, including front and back clamping stations, among which the positive station (side A) clamps and processes the first side; the reverse station (side B) flips and clamps and processes the parts that cannot be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com