Transverse cushioning, energy absorption, anti-seismic and anti-drop beam structure with conical butting balls and check blocks

A technology for cross-bridge and anti-drop beams, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of irreparable stoppers, beam body damage, damage, etc., to avoid beam body partial damage, long life, absorbing High effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The conception, specific details and obtained technical effects of the present invention will be further described below in conjunction with the accompanying drawings.

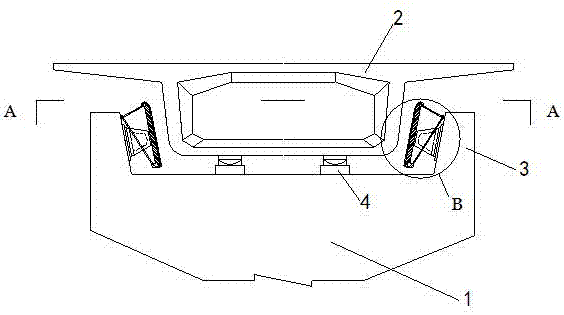

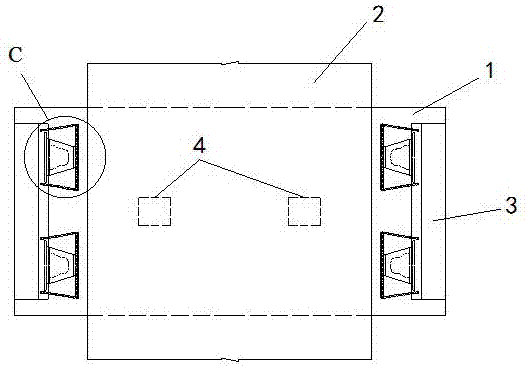

[0030] Such as Figure 1 to Figure 7 Shown, the present invention a kind of horizontal bridge to cone-shaped rubber to rely on the ball buffer anti-seismic stopper anti-falling beam structure

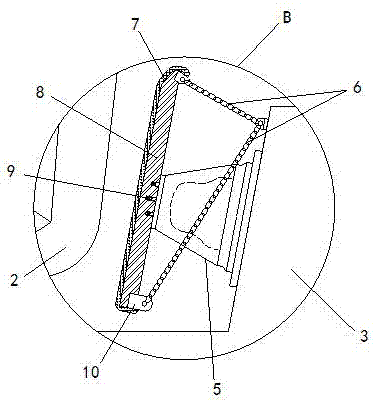

[0031] A specific embodiment includes a tapered rubber ball (5), a steel frame anti-shock plate (8), a veneer (7), an iron chain (6), and a trapezoidal block body (3). The bridge selected in this embodiment is a prestressed concrete bridge, and the bridge anti-seismic block structure and arrangement method are also applicable to other bridge types such as steel bridges.

[0032] Such as Figure 1 to Figure 4 As shown, the pier top cover beam (1) is provided with a support (4), the trapezoidal block body (3) is arranged on both sides of the pier top cover beam (1), and the inner side of the trapezoidal block blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com