Method for efficiently producing KMTB (alpha-keto-gamma-methylthiobutyric acid)

A high-yield, amino acid technology, applied in the field of bioengineering, can solve the problems of increasing cost, protein denaturation, affecting the utilization of D-amino acid oxidase, etc., and achieve the effect of improving production efficiency and high vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

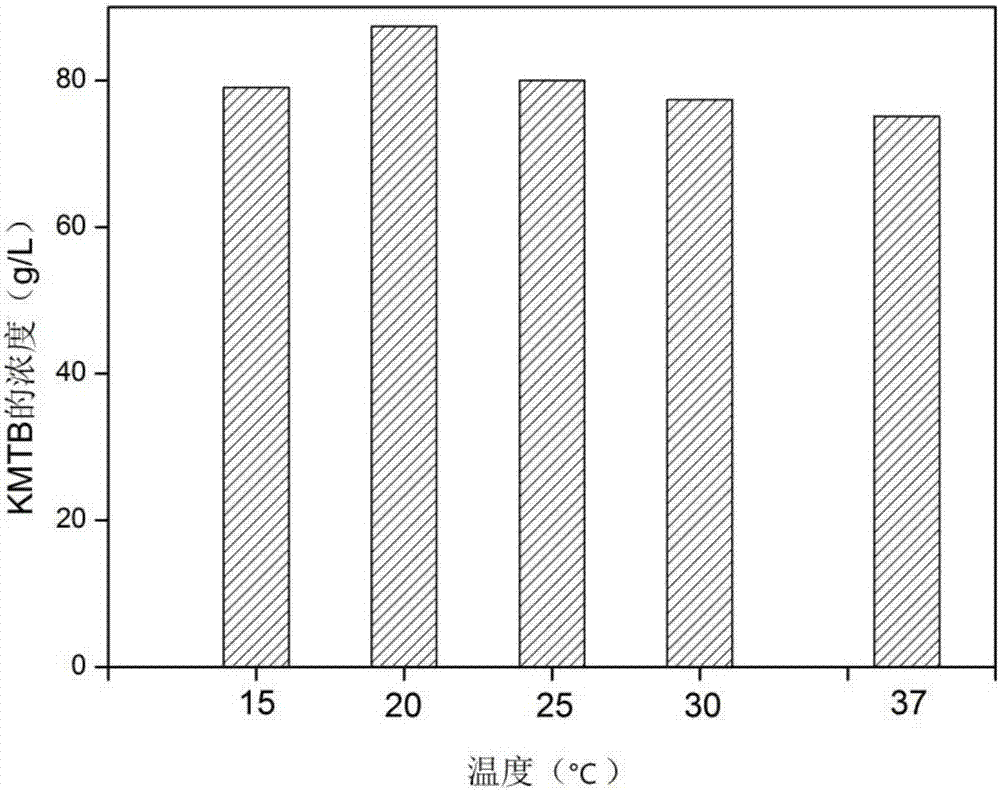

Image

Examples

Embodiment 1

[0032] Embodiment 1: Containing the construction of L-amino acid oxidase genetically engineered bacteria

[0033] (1) The codon-optimized artificially synthesized L-AAO deaminase gene containing BamHI and XhoI restriction sites, as shown in SEQ ID NO.2.

[0034] (2) Digest the target gene and expression vector pET28a at 37°C for 2 hours with restriction endonucleases BamHI and XhoI;

[0035] (3) Ligate the target gene and plasmid pET28a after digestion and gel recovery with T4 ligase at 16°C for 10 h;

[0036] (4) Introduce the constructed expression plasmid into E.coli BL21(DE3), and culture it on the LB plate containing kanamycin for 12h;

[0037] (5) Perform PCR and enzyme digestion verification on the colonies grown on the plate, and perform sequencing verification on the plasmid containing the target gene, and select the strain with the correct target gene, which is the genetically engineered strain expressing L-amino acid oxidase E.coli BL21-L-AAO.

Embodiment 2

[0038] Embodiment 2: Induced expression of genetically engineered bacteria

[0039] (1) Insert the constructed genetically engineered bacteria E.coli BL21-L-AAO into LB slant medium and cultivate for 12 hours;

[0040] (2) Put a ring of slanted seeds into the LB medium and cultivate for 6 hours;

[0041] (3) Put the E.coli BL21-L-AAO seed liquid into the TB fermentation medium and cultivate it to OD 600 0.6, adding IPTG with a final concentration of 0.4mM for induction, after induction at 25°C for 12 hours, the cells were collected, and the cells were washed with sterile normal saline.

Embodiment 3

[0042] Embodiment 3: the influence of different bacterial body weights on the production of α-keto-γ-methylthiobutyric acid

[0043]The wet thallus obtained in Example 2 was taken, collected by centrifugation and used as a catalyst for whole cell transformation. The pH is controlled to be 8.0, the temperature is 30°C, and the addition amount of bacteria is adjusted (30g / L, 40g / L, 50g / L, 60g / L). The reaction solution included L-methionine with a final concentration of 100 g / L and 20 mM Tris-HCL. After converting 24h, the situation of the concentration of α-keto-γ-methylthiobutyric acid in the supernatant liquid after adopting high performance liquid chromatography to measure reaction (such as figure 2 shown), when the final concentration of bacterium was 30g / L, the concentration of α-keto-γ-methylthiobutyric acid was 77.45g / L; when the bacterium was 40g / L, the concentration of α-keto-γ -The concentration of methylthiobutyric acid is 94.46g / L; when the final concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com