Core-shell type oil-based drilling fluid plugging and bridging particle and preparation method thereof

An oil-based drilling fluid and particle technology, applied in chemical instruments and methods, drilling compositions, products, etc., can solve problems such as the limitation of plugging performance, the lack of dispersion performance of calcium carbonate particles, and the lack of pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

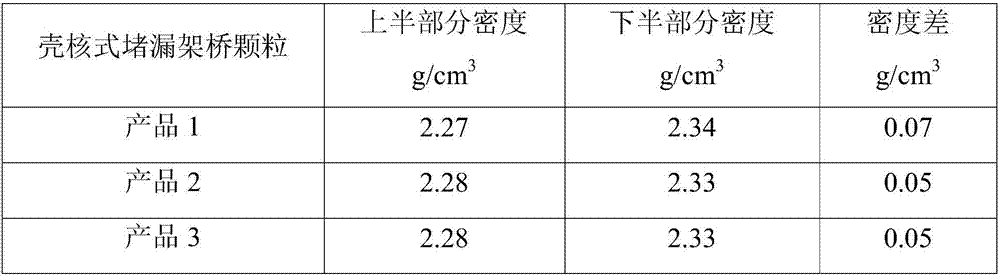

Embodiment 1

[0018] A core-shell type oil-based drilling fluid plugging and bridging particles, prepared by the following method: first, 30 parts by weight of butyl acrylate, 30 parts by weight of styrene, 25 parts by weight of stearyl methacrylate, 0.3 parts by weight Parts of oligomeric siloxane with a degree of polymerization of 2 to 4 and 0.1 part by weight of azobisisobutyronitrile were added to the reaction kettle in sequence, and under nitrogen protection, the temperature was raised to 50°C, and the reaction was carried out at a constant temperature for 24 hours under stirring to obtain lipophilic high polymer; then the prepared lipophilic high polymer is poured into the tray, the calcium carbonate particles are placed in the tray and the tray is slightly shaken, so that the lipophilic high polymer is evenly and completely coated on the calcium carbonate particles Surface; Finally, put the calcium carbonate particles coated with lipophilic polymer layer in another tray, and bake in a...

Embodiment 2

[0020] A core-shell type oil-based drilling fluid plugging and bridging particles, prepared by the following method: first, 40 parts by weight of butyl acrylate, 40 parts by weight of styrene, 25 parts by weight of stearyl methacrylate, 0.2 parts by weight Parts of oligomeric siloxane with a degree of polymerization of 2 to 4 and 0.2 parts by weight of azobisisobutyronitrile were added to the reaction kettle in sequence. Under nitrogen protection, the temperature was raised to 50°C, and the temperature was reacted for 24 hours under stirring to obtain lipophilic high polymer; then the prepared lipophilic high polymer is poured into the tray, the calcium carbonate particles are placed in the tray and the tray is slightly shaken, so that the lipophilic high polymer is evenly and completely coated on the calcium carbonate particles Surface; Finally, put the calcium carbonate particles coated with lipophilic polymer layer in another tray, and bake in an oven at 105°C for 2 hours, t...

Embodiment 3

[0022] A core-shell type oil-based drilling fluid plugging and bridging particles, prepared by the following method: first, 35 parts by weight of butyl acrylate, 35 parts by weight of styrene, 20 parts by weight of stearyl methacrylate, 0.2 parts by weight Parts of oligomeric siloxane with a degree of polymerization of 2 to 4 and 0.15 parts by weight of azobisisobutyronitrile were added to the reaction kettle in sequence, and the temperature was raised to 52°C under nitrogen protection, and the reaction was carried out at a constant temperature for 24 hours under stirring to obtain lipophilic high polymer; then the prepared lipophilic high polymer is poured into the tray, the calcium carbonate particles are placed in the tray and the tray is slightly shaken, so that the lipophilic high polymer is evenly and completely coated on the calcium carbonate particles Surface; Finally, put the calcium carbonate particles coated with lipophilic polymer layer in another tray, and bake in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com