A kind of hydrophilic polyester and preparation method thereof

A water-polyester and hydrophilic technology, applied in the field of polymers, can solve the problems of large viscosity drop and easy yellowing of hydrophilic polyesters, and achieve low production energy consumption, good product quality stability, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

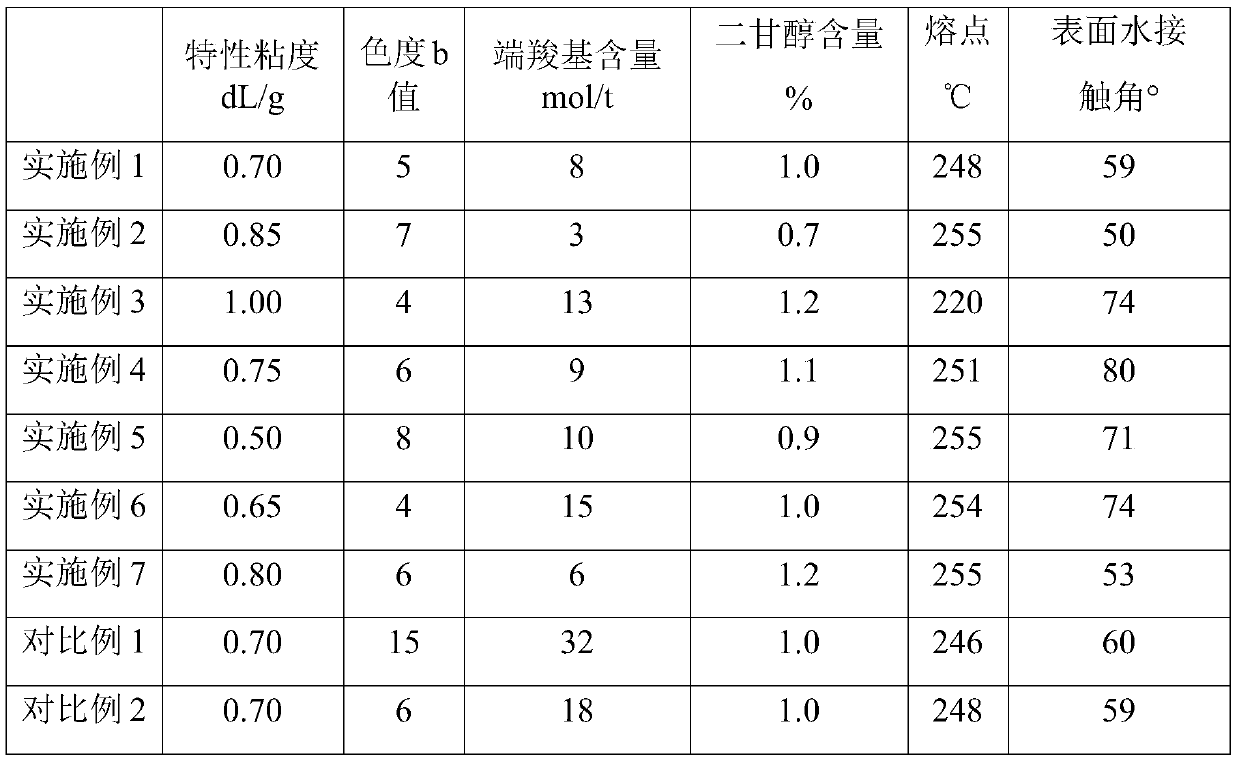

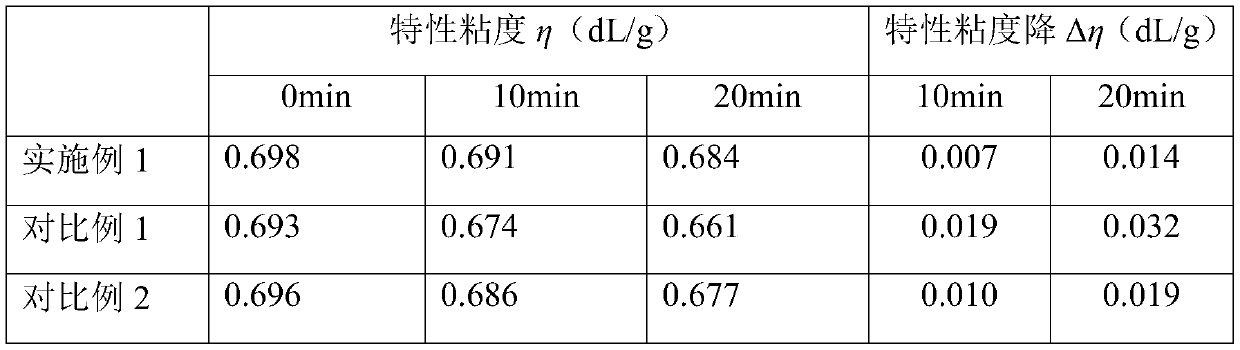

Examples

Embodiment 1

[0047] Prepare hydrophilic polyester according to the preparation method provided by the invention, the steps are as follows:

[0048] (1) Terephthalic acid and ethylene glycol are prepared into a slurry according to a molar ratio of 1:1.15;

[0049] (2) The slurry prepared in step (1) is continuously added to the esterification system composed of the first vertical esterification kettle and the second vertical esterification kettle for esterification reaction. The reaction temperature of the first esterification kettle is The reaction temperature of the second esterification tank is 265°C and the reaction pressure is 120kPa. When the degree of polymerization of the ethylene terephthalate oligomer reached 5, the oligomer was continuously and stably extracted from the esterification kettle by the oligomer pump;

[0050] (3) After the ethylene terephthalate oligomer prepared in step (2) is adjusted to 235° C. through a heat exchanger, it is mixed with polyethylene glycol and di...

Embodiment 2

[0054] Prepare hydrophilic polyester according to the preparation method provided by the invention, the steps are as follows:

[0055] (1) Terephthalic acid and ethylene glycol are prepared into a slurry according to a molar ratio of 1:1.05;

[0056] (2) The slurry prepared in step (1) is continuously added to the esterification system composed of the first vertical esterification kettle and the second vertical esterification kettle for esterification reaction. The reaction temperature of the first esterification kettle is The reaction temperature of the second esterification tank is 275°C and the reaction pressure is 200kPa. When the degree of polymerization of the ethylene terephthalate oligomer reaches 8, the oligomer is continuously and stably extracted from the esterification tank by the oligomer pump;

[0057] (3) After the ethylene terephthalate oligomer prepared in step (2) is adjusted to 250°C through a heat exchanger, it is mixed with polyethylene glycol with a mole...

Embodiment 3

[0061] Prepare hydrophilic polyester according to the preparation method provided by the invention, the steps are as follows:

[0062] (1) Terephthalic acid and ethylene glycol are prepared into a slurry according to a molar ratio of 1:2.0;

[0063] (2) The slurry prepared in step (1) is continuously added to the esterification system composed of a vertical esterification tank for esterification reaction. The reaction temperature of the esterification tank is 240 ° C and the reaction pressure is 100 kPa. When the degree of polymerization of the ethylene glycol diformate oligomer reaches 1, the oligomer is continuously and stably taken out from the esterification kettle by the oligomer pump;

[0064] (3) After the ethylene terephthalate oligomer prepared in step (2) is adjusted to 200°C through a heat exchanger, it is mixed with polyethylene glycol and glycerol / phosphorous acid with a molecular weight of 200 added online Triphenyl ester / N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com