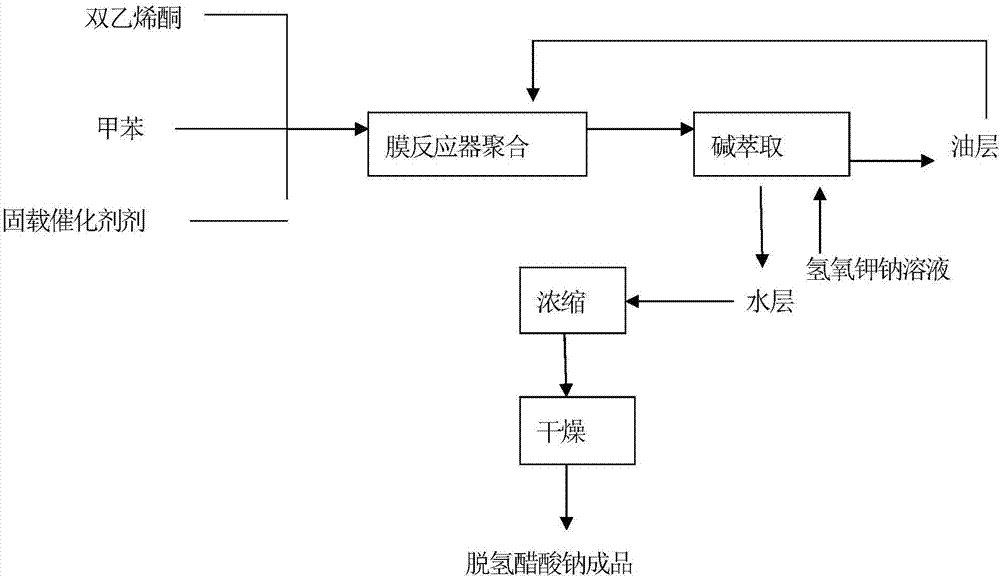

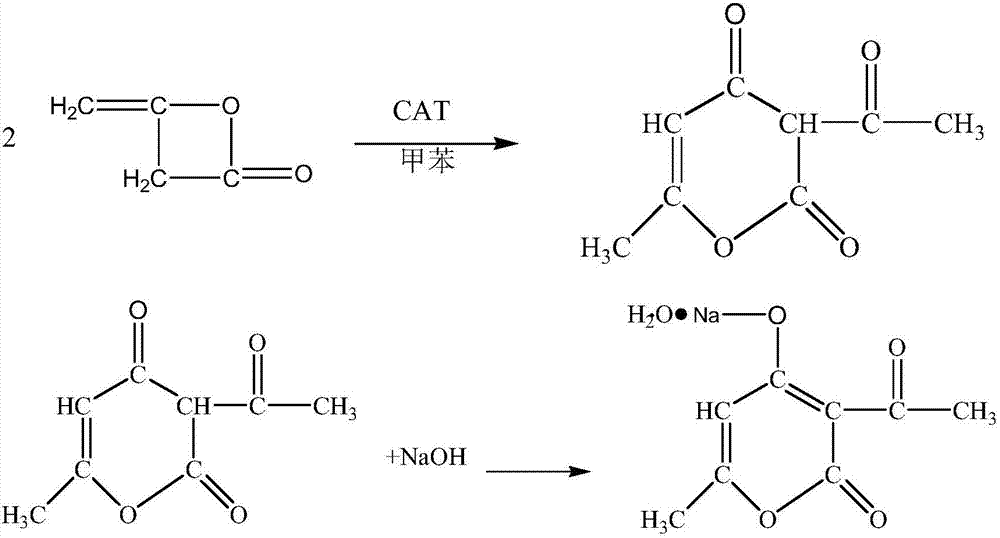

Technology for preparing sodium dehydroacetate in membrane reactor with immobilized catalyst

A technology of sodium dehydroacetate and membrane reactor, which is applied in the field of preparation technology of sodium dehydroacetate, can solve the problems of difficult separation of by-products of diketene polymerization, unrecoverable catalyst, etc., and achieves high catalytic activity, reaction selectivity, and mechanical strength. High, improve the effect of reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) First, toluene is injected into the ceramic membrane reactor equipped with a solid-supported catalyst, the circulation pump is turned on, and then the diketene feeding pump is turned on, and the diketene feeding pump is turned on within 0.5h. The feed mass ratio of diketene and toluene is 1:5 The reaction temperature is controlled to 50°C, the reactor pressure is controlled to 0.8MPa, and the catalyst addition amount is 0.5wt% of the total feed amount (the total mass of the mixed solution of the catalyst, diketene and toluene). The ceramic nanofiltration membrane is made of Al 2 O 3 With TiO 2 Manufactured, the membrane pore size is 1~2nm;

[0038] 2) The solid supported catalyst KOH-NaOH / Al described in step 1 2 O 3 It is prepared by dipping method, KOH-NaOH is used as the active component, the mass ratio of KOH to NaOH is 1:1, the active component is weighed and prepared into a 20wt% aqueous solution, the carrier is Al2O3, the particle size is 100 mesh, and the active ...

Embodiment 2

[0041] 1) First, toluene is injected into the ceramic membrane reactor equipped with a solid-supported catalyst, the circulation pump is turned on, and then the diketene feeding pump is turned on, and the diketene feeding pump is turned on within 1 hour. The feed mass ratio of diketene and toluene is 1:10. The reaction temperature is controlled at 60°C, the reactor pressure is controlled at 1 MPa, and the catalyst addition amount is 0.5 wt% of the total feed amount (the total mass of the mixed solution of the catalyst, diketene and toluene). The ceramic nanofiltration membrane is made of Al 2 O 3 With TiO 2 Manufactured, the membrane pore size is 1~2nm;

[0042] 2) The supported catalyst KOH-NaOH / SiO as described in step 1 2 Prepared by dipping method, with KOH-NaOH as the active component, the mass ratio of KOH to NaOH is 2:1, weigh the active component and prepare a 25wt% aqueous solution, the carrier is SiO 2 , The particle size is 200 meshes, the active component accounts for ...

Embodiment 3

[0045] 1) First, toluene is injected into the ceramic membrane reactor equipped with a solid-supported catalyst, the circulation pump is turned on, and then the diketene feeding pump is turned on, and the diketene feeding pump is turned on within 1 hour. The feed mass ratio of diketene and toluene is 1:15. The reaction temperature is controlled at 70°C, the reactor pressure is controlled at 2MPa, and the catalyst addition amount is 3wt% of the total feed amount (the total mass of the mixed solution of the catalyst, diketene and toluene). The ceramic nanofiltration membrane is made of Al 2 O 3 With TiO 2 Manufactured, the membrane pore size is 1~2nm;

[0046] 2) The solid-supported catalyst KOH-NaOH / ZSM-5 described in step 1 is prepared by an impregnation method, with KOH-NaOH as the active component, and the mass ratio of KOH to NaOH is 3:1. Weigh the active component and prepare 30wt% aqueous solution, the carrier is ZSM-5, the particle size is 300 mesh, the ratio of the active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com