Alumina fiber reinforced nitride based wave permeable composite material and preparation method thereof

A technology of alumina fiber and composite materials, which is applied in the field of alumina fiber-reinforced nitride-based wave-transparent composite materials and its preparation, can solve the problems of unreported high-temperature mechanical properties, complicated and time-consuming three-dimensional weaving process, and poor overall mechanical properties of materials To achieve the effects of improving cross-linking curing efficiency, reducing air pressure, improving high-temperature mechanical properties and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

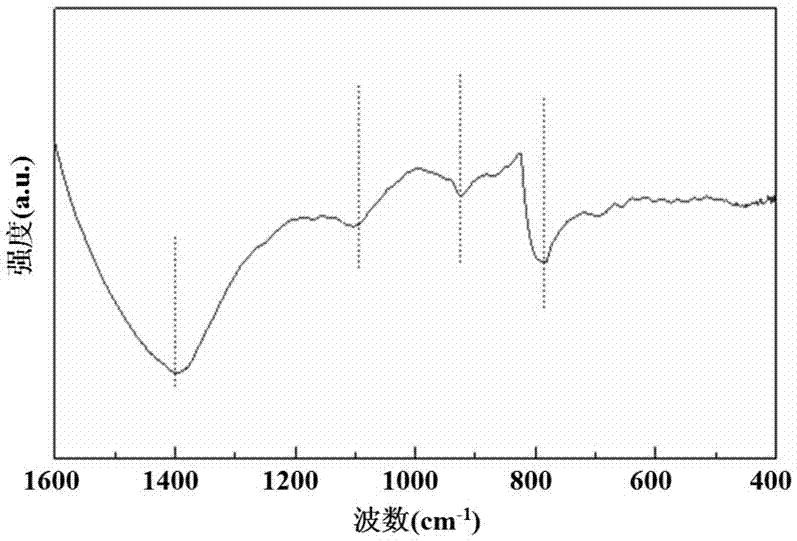

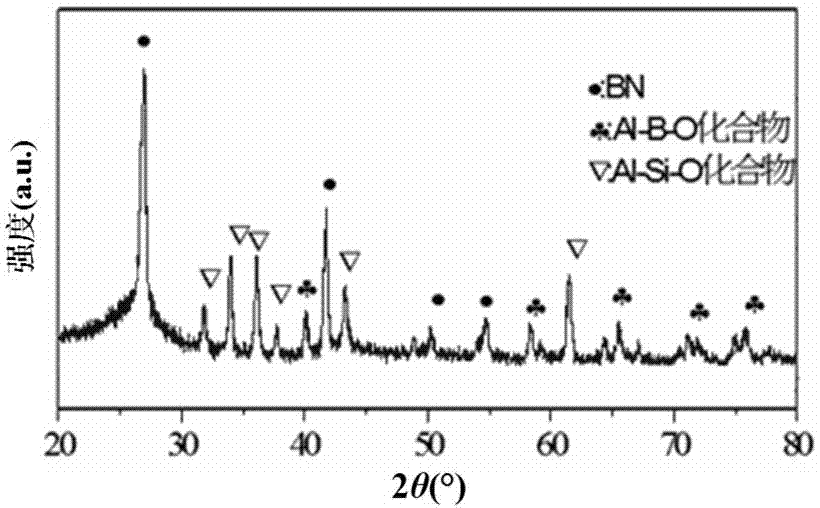

Method used

Image

Examples

Embodiment 1

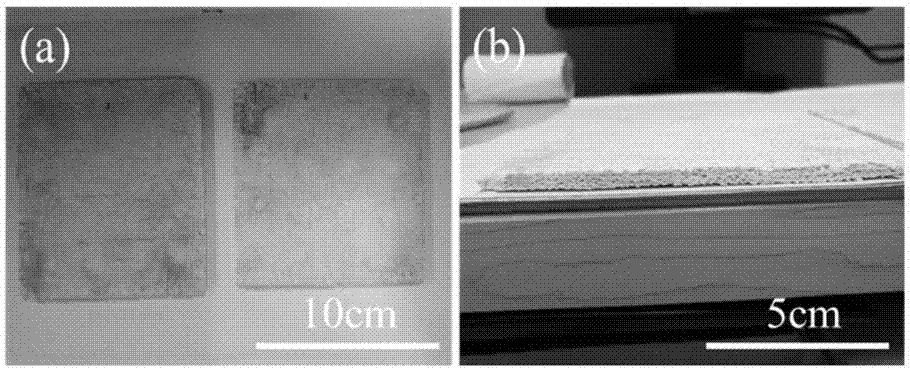

[0032] A preparation method of alumina fiber reinforced nitride-based wave-transparent composite material of the present invention, comprising the following steps:

[0033] (1) Laminate and compact the alumina two-dimensional fiber cloth, and stitch the alumina fiber along the longitudinal direction (stacking direction) to make the alumina three-dimensional fiber prefabricated part. The volume fraction of the alumina fiber is 38vol%, and the density of the longitudinal stitching is 2×2 needles / cm 2 ;

[0034] (2) The aluminum oxide three-dimensional fiber preform obtained in step (1) is subjected to debinding treatment. The debinding process is as follows: the temperature is raised to 800°C at a rate of 10°C / min, and the temperature is kept for 5 hours;

[0035] (3) Put the degummed fiber preform obtained in step (2) into an airtight container, evacuate the container to below 500Pa, inhale an appropriate amount of liquid borazine precursor, and let it stand for 60 minutes to ...

Embodiment 2

[0043] A preparation method of alumina fiber reinforced nitride-based wave-transparent composite material of the present invention, comprising the following steps:

[0044] (1) Laminate and compact the alumina two-dimensional fiber cloth, and stitch the alumina fiber along the longitudinal direction (stacking direction) to make the alumina three-dimensional fiber prefabricated part, wherein the volume fraction of the alumina three-dimensional fiber is 42vol%, and the longitudinal stitching The density is 2×2 needles / cm 2 ;

[0045] (2) The aluminum oxide three-dimensional fiber preform obtained in step (1) is subjected to debinding treatment. The debinding process is as follows: the temperature is raised to 800°C at a rate of 10°C / min, and the temperature is kept for 5 hours;

[0046] (3) Put the alumina three-dimensional fiber prefabricated part after degumming obtained in step (2) into a closed container, vacuum the container below 500Pa, inhale an appropriate amount of liq...

Embodiment 3

[0051] A preparation method of alumina fiber reinforced nitride-based wave-transparent composite material of the present invention, comprising the following steps:

[0052] (1) Laminate and compact the alumina two-dimensional fiber cloth, and stitch the alumina fiber along the longitudinal direction (stacking direction) to make the alumina three-dimensional fiber prefabricated part. The volume fraction of the alumina three-dimensional fiber is 40vol%, and the density of the longitudinal stitching is 2×2 stitches / cm 2 ;

[0053] (2) The aluminum oxide three-dimensional fiber preform obtained in step (1) is subjected to debinding treatment. The debinding process is as follows: the temperature is raised to 800°C at a rate of 10°C / min, and the temperature is kept for 5 hours;

[0054] (3) Put the alumina three-dimensional fiber prefabricated part after degumming obtained in step (2) into a closed container, vacuum the container below 500Pa, inhale an appropriate amount of liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com