Drug testing reagent kit and manufacturing method thereof

A manufacturing method and kit technology, applied to other household appliances, household components, household appliances, etc., can solve the problems of poor quality of reagent bottles and caps, and achieve the requirements of aesthetic appearance, convenient use, and reduced pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

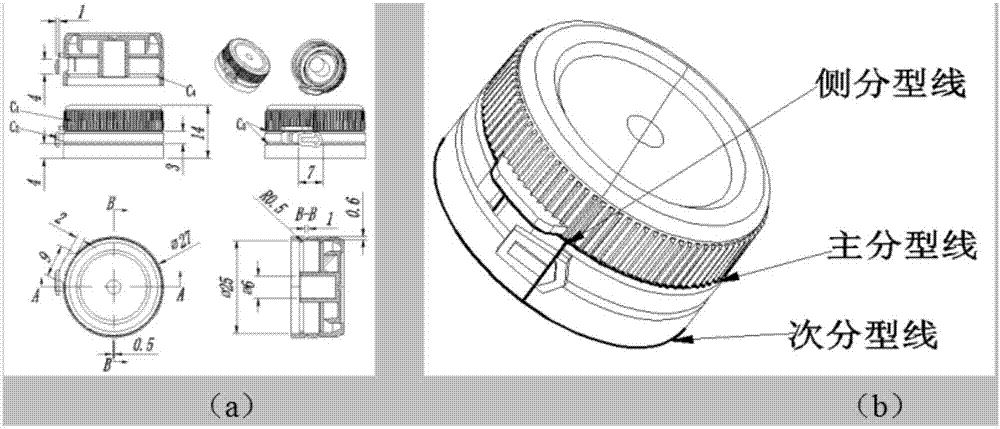

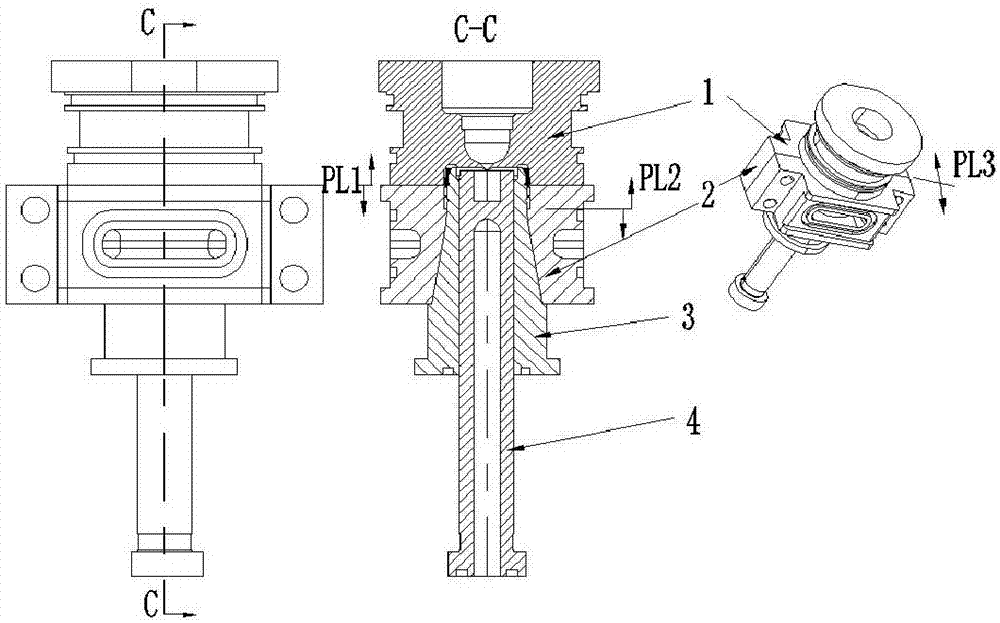

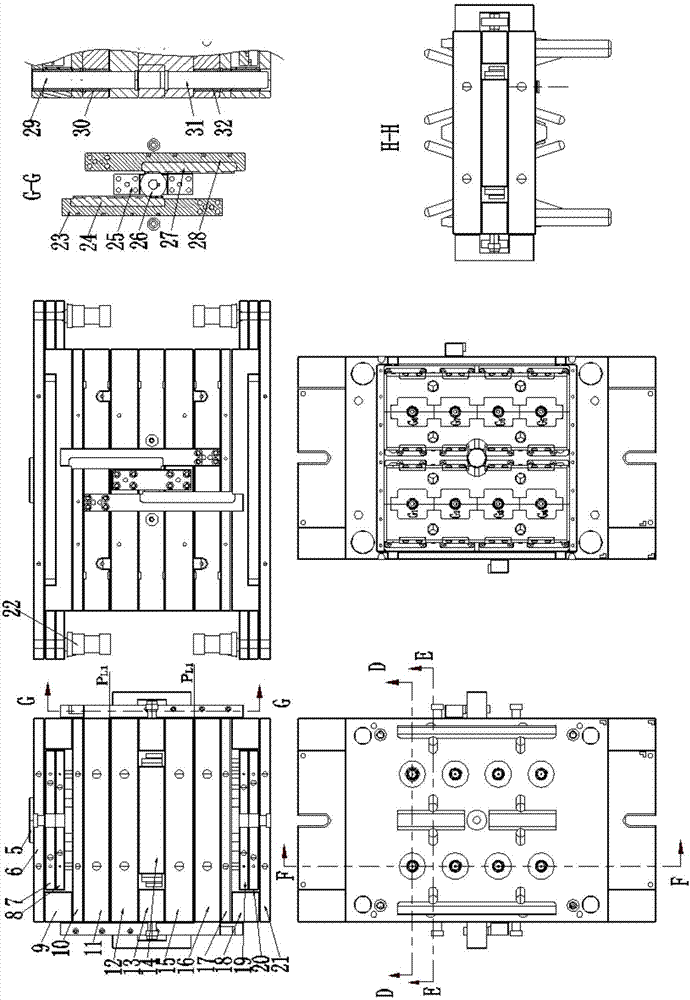

[0030] Figure 1-5 Shown is the relevant explanatory figure of the present invention; figure 1 , figure 2 As shown in the analysis, a hot runner injection mold for a bottle cap laminated mold includes a cavity insert 1, a side cavity insert 2, a core insert 3, a central core insert 4, a positioning ring 5, and an upper bottom plate 6 , Upper push plate 7, Upper ejection panel 8, Upper mold foot block 9, Upper backing plate 10, Upper core fixing plate 11, Upper cavity fixing plate 12, Runner space pad 13, Central hot runner plate 14 , Lower cavity fixed plate 15, lower core fixed plate 16, lower backing plate 17, lower mold foot block 18, lower ejector panel 19, lower push plate 20, lower bottom plate 21, top plate oil cylinder 22, mold opening active pull Bar 23, mold opening driving rack 24, gear mounting block 25, transmission gear 26, mold opening driven rack 27, mold opening driven pull bar 28, upper mold guide post 29, upper mold guide sleeve 30, lower mold guide Colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com