Dust treatment device purifying filter element by virtue of compressed air

A technology for dust treatment and compressed air, which is applied in membrane filter, dispersed particle filtration, transportation and packaging, etc. It can solve problems such as production environment or warehouse explosion, achieve good effect, simple principle and structure, and improve occupational health conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

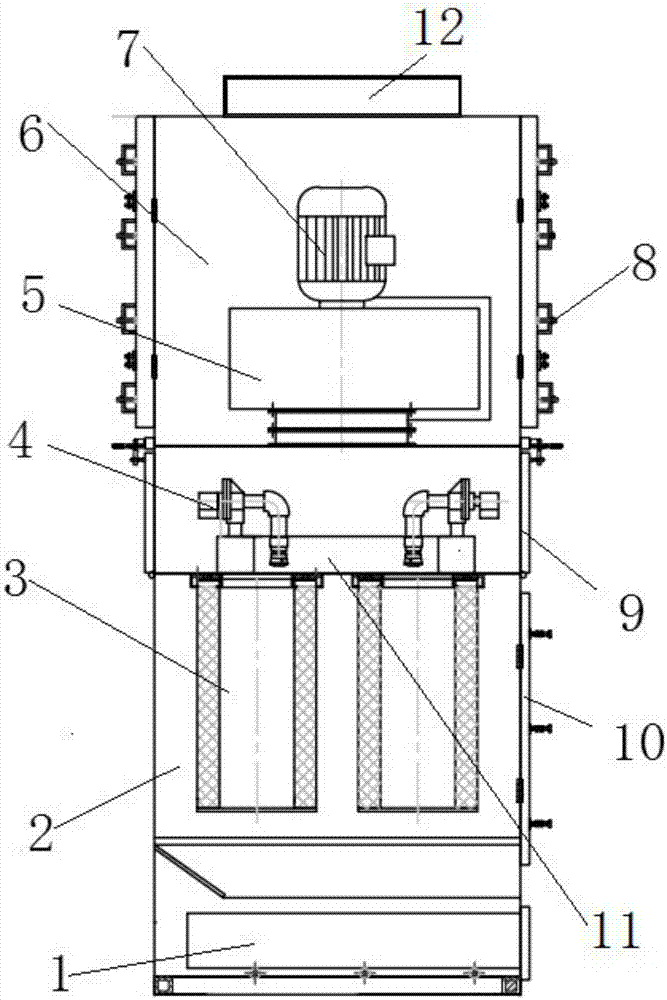

[0018] The present invention provides a dust treatment device for purifying the filter element by compressed air, which is characterized in that: the dust treatment device for purifying the filter element by compressed air comprises a recovery powder box 1, a lower base 2, a cylindrical filter system 3, Pulse valve 4, air induction system 5, upper cover body 6, motor 7, high efficiency filter 8, inspection door 9, pressure regulating device 10, air bag 11, filter device 12;

[0019] Wherein: the recovered powder box 1 is arranged at the bottom of the lower base 2, the cylindrical filter system 3 is arranged in the lower base 2, and the cylindrical filter system 3 is connected with the air induction system 5 through the pulse valve 4;

[0020] After the air induction system 5 is connected with the motor 7, it is arranged in the upper cover body 6, and a high-efficiency filter 8 is installed on the side of the upper cover body 6, and the maintenance door 9 is arranged on the side...

Embodiment 2

[0028] The present invention provides a dust treatment device for purifying the filter element by compressed air, which is characterized in that: the dust treatment device for purifying the filter element by compressed air comprises a recovery powder box 1, a lower base 2, a cylindrical filter system 3, Pulse valve 4, air induction system 5, upper cover body 6, motor 7, high efficiency filter 8, inspection door 9, pressure regulating device 10, air bag 11, filter device 12;

[0029] Wherein: the recovered powder box 1 is arranged at the bottom of the lower base 2, the cylindrical filter system 3 is arranged in the lower base 2, and the cylindrical filter system 3 is connected with the air induction system 5 through the pulse valve 4;

[0030] After the air induction system 5 is connected with the motor 7, it is arranged in the upper cover body 6, and a high-efficiency filter 8 is installed on the side of the upper cover body 6, and the maintenance door 9 is arranged on the side...

Embodiment 3

[0036] The present invention provides a dust treatment device for purifying the filter element by compressed air, which is characterized in that: the dust treatment device for purifying the filter element by compressed air comprises a recovery powder box 1, a lower base 2, a cylindrical filter system 3, Pulse valve 4, air induction system 5, upper cover body 6, motor 7, high efficiency filter 8, inspection door 9, pressure regulating device 10, air bag 11, filter device 12;

[0037] Wherein: the recovered powder box 1 is arranged at the bottom of the lower base 2, the cylindrical filter system 3 is arranged in the lower base 2, and the cylindrical filter system 3 is connected with the air induction system 5 through the pulse valve 4;

[0038] After the air induction system 5 is connected with the motor 7, it is arranged in the upper cover body 6, and a high-efficiency filter 8 is installed on the side of the upper cover body 6, and the maintenance door 9 is arranged on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com