Preparation method of bacteriostatic deodorized durable deodorizing agent

A deodorant and durable technology, which is applied in the field of deodorant preparation, can solve the problems of poor antibacterial properties of deodorant and unsustainable deodorizing effect, achieve long-lasting deodorizing time, increase light utilization rate, and improve catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

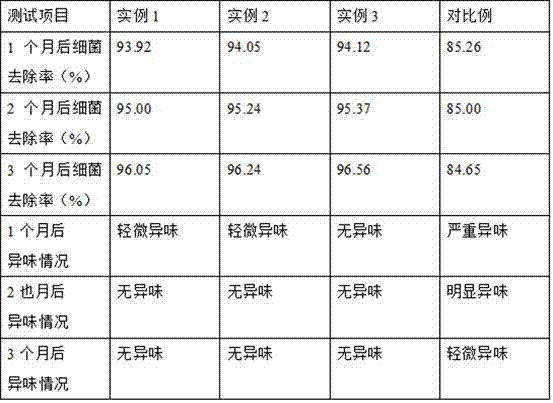

Examples

example 1

[0026]Weigh 100g of high-titanium slag and 30g of sodium bicarbonate, place them in a resistance furnace, heat up to 1200°C with a power program, calcine at high temperature for 2 hours, and naturally cool to room temperature to obtain light-burned high-titanium slag. Place light-burned high-titanium slag in In a three-necked flask with a stirrer, add 200mL of hydrochloric acid with a mass fraction of 20% into the three-necked flask, start the agitator, stir and mix at a speed of 400r / min for 1.0h, let it stand for 10h, filter with suction, remove the residue, and obtain four Titanium chloride solution; add 100mL of the above-mentioned titanium tetrachloride solution to a three-necked flask with a reflux device and a stirrer, start the stirrer, stir at a speed of 250r / min, heat up to 70°C, and add 5g of rutile to the three-necked flask Type titanium dioxide, continue to heat up to 110 ° C, hydrolysis reaction 1.5h, discharge, to obtain nano-titanium dioxide; weigh 40g of diatom...

example 2

[0028] Weigh 110g of high-titanium slag and 35g of sodium bicarbonate, place them in a resistance furnace, power on and heat up to 1220°C, calcine at high temperature for 2.5 hours, and cool to room temperature naturally to obtain light-burned high-titanium slag, place light-burned high-titanium slag in In a three-necked flask with a stirrer, add 210mL of hydrochloric acid with a mass fraction of 20% into the three-necked flask, start the agitator, stir and mix at a speed of 410r / min for 1.2h, let stand for 11h, filter with suction, remove the residue, and obtain four Titanium chloride solution; add 110mL of the above-mentioned titanium tetrachloride solution to a three-necked flask with a reflux device and a stirrer, start the stirrer, stir at a speed of 260r / min, heat up to 75°C, and add 6g of rutile to the three-necked flask Type titanium dioxide, continue to heat up to 115°C, hydrolyze for 1.7h, and discharge to obtain nano-titanium dioxide; weigh 45g of diatomaceous earth ...

example 3

[0030] Weigh 120g of high-titanium slag and 40g of sodium bicarbonate, place them in a resistance furnace, power on and heat up to 1250°C, calcine at high temperature for 3 hours, and cool naturally to room temperature to obtain light-burned high-titanium slag, place light-burned high-titanium slag in In a three-necked flask with a stirrer, add 220mL of hydrochloric acid with a mass fraction of 20% into the three-necked flask, start the agitator, stir and mix at a speed of 420r / min for 1.2h, let it stand for 11h, filter with suction, remove the residue, and obtain four Titanium chloride solution; add 110mL of the above-mentioned titanium tetrachloride solution to a three-necked flask with a reflux device and a stirrer, start the stirrer, stir at a speed of 260r / min, heat up to 75°C, and add 6g of rutile to the three-necked flask Type titanium dioxide, continue to heat up to 115 ° C, hydrolysis reaction 1.7h, discharge, to obtain nano-titanium dioxide; weigh 45g of diatomaceous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com