Transformer lug welding equipment

A technology for welding equipment and lugs, applied in connection, coil manufacturing, circuit/collector components, etc., can solve problems such as affecting bearing performance, increasing the maintenance of bearings and other components, and affecting the welding efficiency of the welding mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

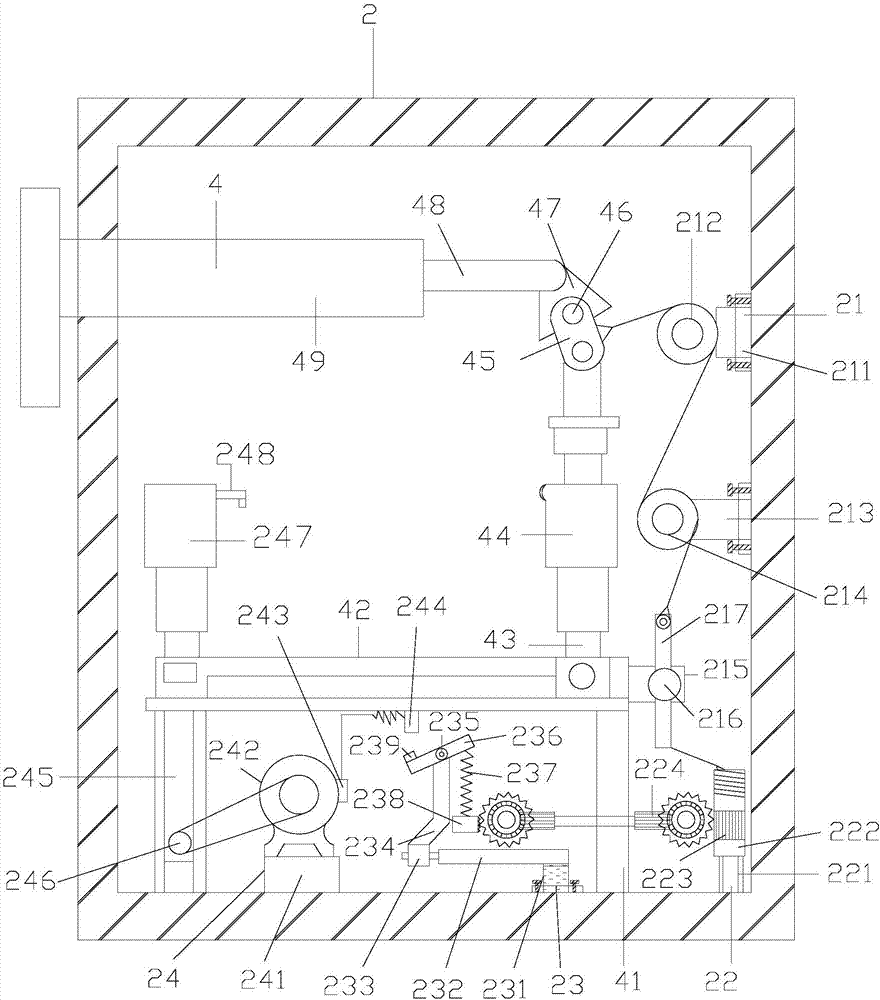

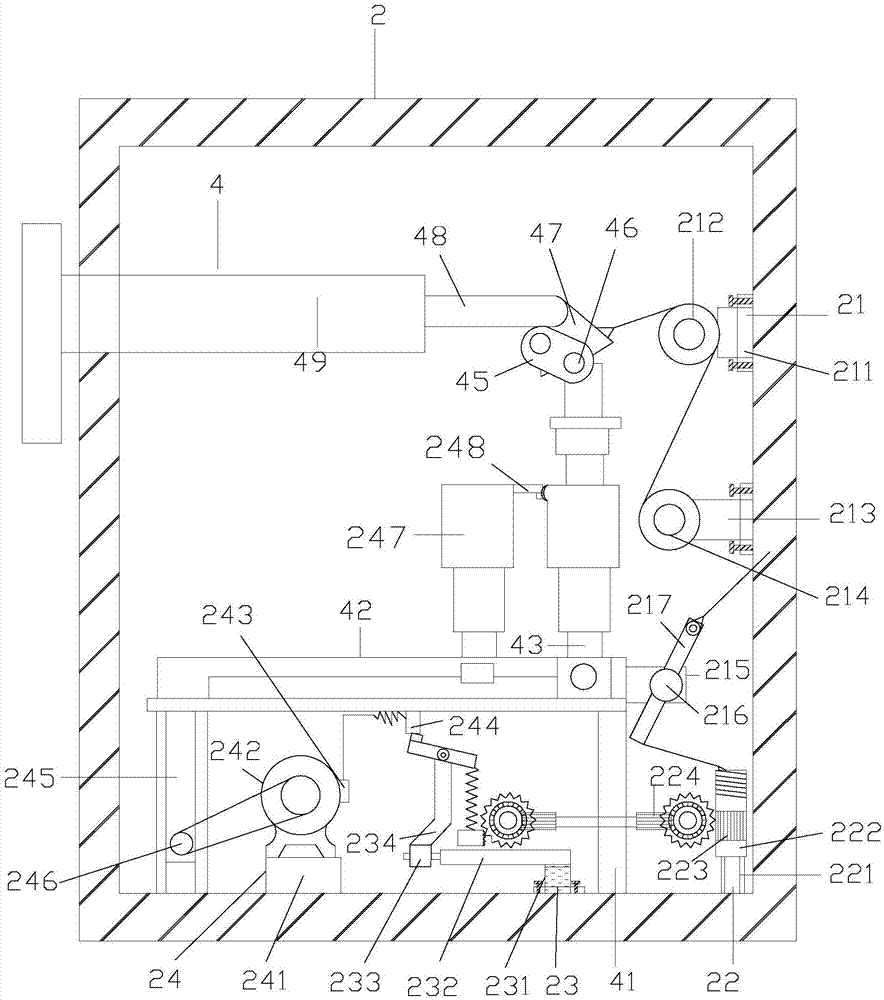

[0020] see Figure 1-Figure 4 , the present invention provides a transformer lug welding equipment, the structure of which includes a frame 1, a self-lubricating chassis 2, an upper workpiece 3, a welding mechanism 4, a welding head 5, a cast iron backing plate 6, and a copper bar 7. The self-lubricating Type chassis 2 is fixedly welded on the right part of the upper surface of frame 1 and they are in the state of being perpendicular to each other. The cabinets 2 are in a state perpendicular to each other. The self-lubricating cabinet 2 is provided with a cavity, and the welding mechanism 4 is movably connected to the internal cavity of the self-lubricating cabinet 2 and its left half runs through the self-lubricating cabinet. 2, the welding head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com