A polymer conductive fiber toughened sulfide composite electrolyte

A composite electrolyte and conductive fiber technology, applied in electrolytes, non-aqueous electrolytes, solid electrolytes, etc., can solve problems such as limiting the development and application of all-solid-state lithium-ion batteries, poor mechanical properties, and poor overall performance of organic-inorganic composite electrolytes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

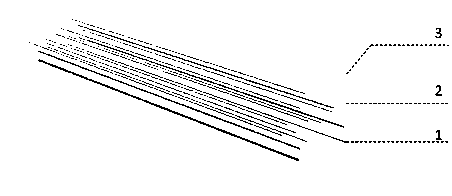

[0023] Dissolve 1 g of polyimide and 0.2 g of LiTFSI in 10 ml of DMF, stir to dissolve completely. Move the solution into an electrospinning machine, and under the action of 30 KV voltage and gravity, the polymer is spun onto a collecting plate equipped with tiny electrodes, and after 60 s, the one-dimensional nanopolymer lithium-ion conductive fibers aligned in alignment are collected and moved into Dry in a vacuum oven at 80°C. 1.9 g Li 3 P.S. 4 Disperse in 10 ml of toluene solution, scrape-coat it on a smooth aluminum foil, and move it into a vacuum oven at 80°C to dry. After drying, the one-dimensional nanopolymer lithium-ion conductive fibers are uniformly arranged in the same direction to the Li 3 P.S. 4 On, heat-compression compounding at 300°C. Repeat the above steps of scraping-arranging fibers-hot pressing to obtain a sulfide composite electrolyte toughened by polymer conductive fibers. The thickness of the electrolyte is 200 μm, and the lithium ion conductivit...

Embodiment 2

[0025] 1 g polyetherimide and 0.2 g LiBF 4 Dissolve in 10 ml DMAC and stir to dissolve completely. The solution was filtered, defoamed, and 0.1 g min -1 The pump supply is wet spinning, and the spinneret with a diameter of 0.01 mm is selected. After solidification and stretching, it is wound and taken up by a winding machine to obtain a stable and continuous one-dimensional nanopolymer lithium ion conductive fiber. 1.9 gLi 6 P.S. 5 Cl was dispersed in 10 ml of toluene solution, scraped onto a smooth aluminum foil, and dried in a vacuum oven at 80°C. After drying, the one-dimensional nanopolymer lithium-ion conductive fibers are uniformly arranged in the same direction to the Li 6 P.S. 5 Cl, at 300 ° C hot-compression composite. Repeat the above steps of scraping-arranging fibers-hot pressing to obtain a sulfide composite electrolyte toughened by polymer conductive fibers. The thickness of the electrolyte is 200 μm, and the lithium ion conductivity of the electrolyte at ...

Embodiment 3

[0027] Dissolve 1 g of Kevlar and 0.2 g of LiBOB in 10 ml of DMAC, stir to dissolve completely. Scrape the solution on a polytetrafluoroethylene plate, dry it in a vacuum oven at 80°C, and crush it into a 100-mesh powder by ultra-cooling and low temperature. Adopt the melt spinning method, set the hot air temperature to 330°C, and the melt flow rate to 3.9 ml min -1 , the air pressure is 4 atm, the polymer is spun onto a collecting plate with tiny electrodes 15 cm away from the spinneret hole, and the aligned one-dimensional nanopolymer lithium ion conductive fibers are collected, and then moved into a 60°C oven for drying. 2.2 g Li 3 P.S. 4 Disperse in 10 ml of toluene solution, scrape-coat it on a smooth aluminum foil, and move it into a vacuum oven at 80°C to dry. After drying, the one-dimensional nanopolymer lithium-ion conductive fibers are uniformly arranged in the same direction to the Li 3 P.S. 4 On, heat-compression compounding at 300°C. Repeat the above steps o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap