Electronic component module and manufacturing method thereof

一种电子部件、制造方法的技术,应用在半导体/固态器件制造、电气元件、电固体器件等方向,能够解决屏蔽剥离、反射率降低等问题,达到附着性高、反射率低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

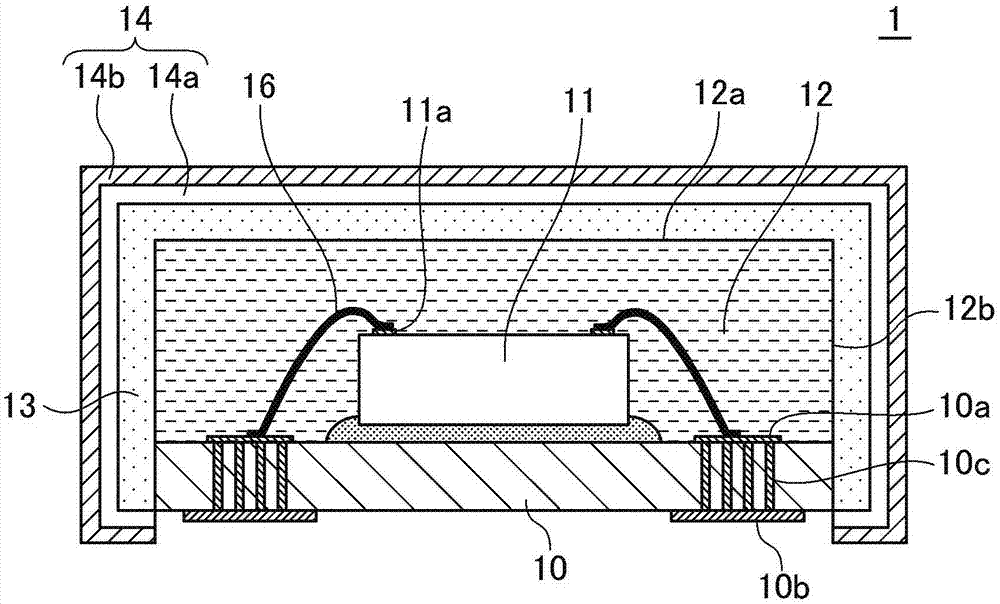

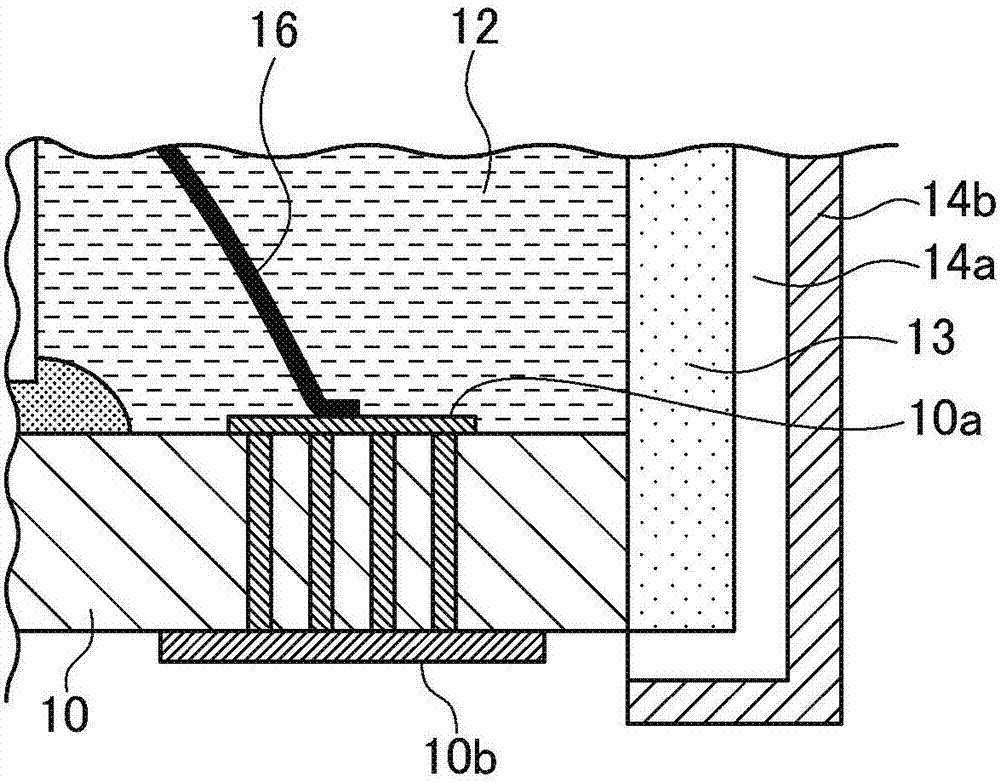

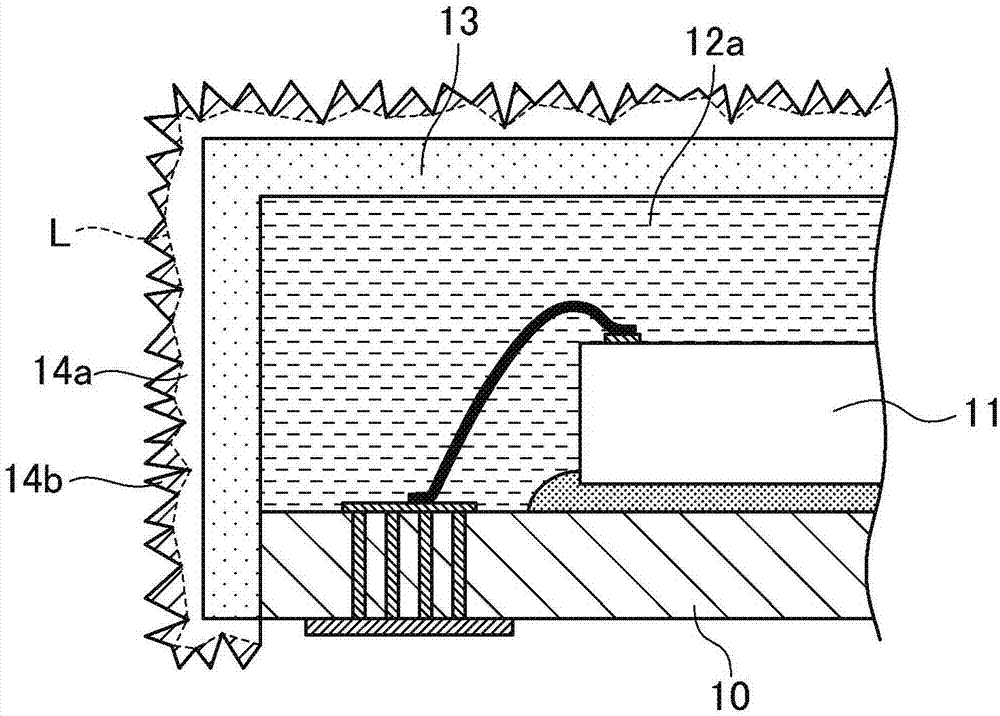

[0047] The actual production has the same figure 1 The samples of Examples 1 to 4 having the same structure as the electronic component module 1 shown have Image 6 A sample of Example 5 having the same structure as the electronic component module 2 shown.

[0048] First, prepare a sample of an electronic component module as an intermediate product in which an electronic component is mounted on a mounting substrate and the electronic component is sealed with a sealing resin (molding resin) containing a filler made of silica (see Figure 4A ). As the mounting board, an FR4 (Flame Retardant Type 4) resin printed circuit board was used.

[0049] Next, a mask tape is pasted on the bottom surface of the mounting substrate to cover the entire bottom surface of the mounting substrate (see Figure 4B ). Next, a conductive film is formed by electroless plating (see Figure 4C ). In the electroless plating process, first, after immersing the electronic component module in an aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com