Parameter optimization method of in-wheel vibration reduction system of electric wheels

A technology of vibration reduction system and optimization method, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as affecting the working performance of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0091] The present invention provides a parameter optimization method for the internal vibration reduction system of an electric wheel, including:

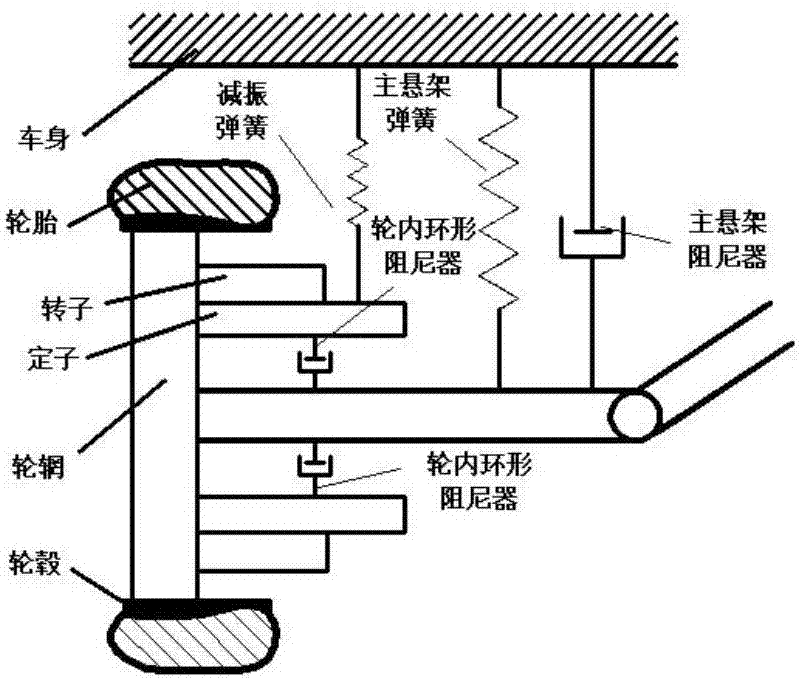

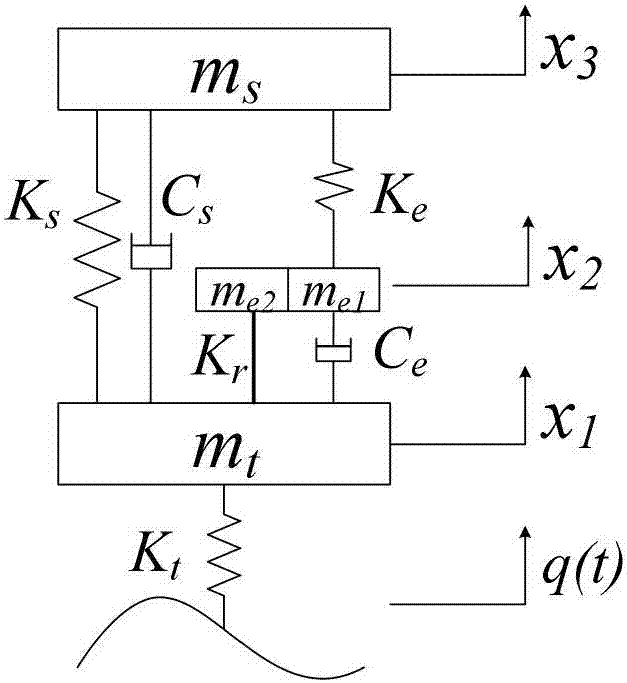

[0092] Such as figure 1 As shown in the two-dimensional schematic diagram, set up as figure 2 The vibration model of the three-degree-of-freedom 1 / 4 vibration-damping electric wheel vehicle is shown, and the dynamic differential equation for the 1 / 4 vibration-damping electric wheel is established as:

[0093]

[0094]

[0095]

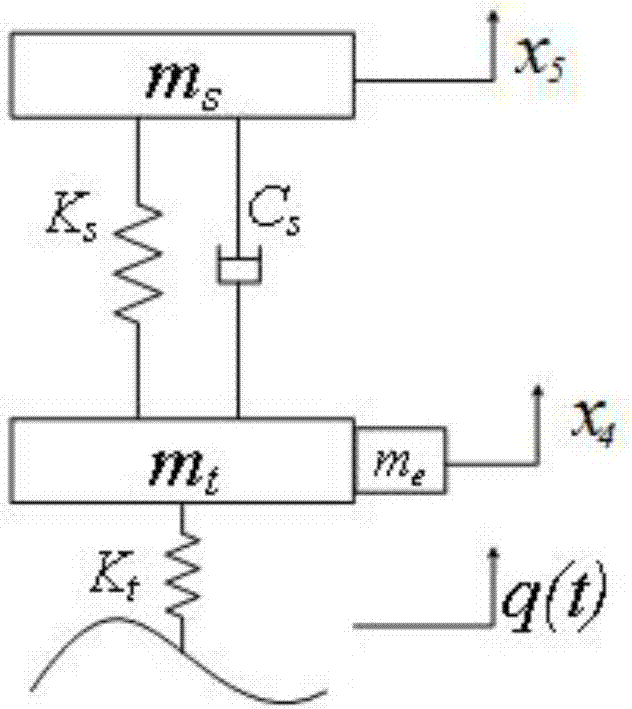

[0096] Such as image 3 As shown, for the original electric wheel vehicle, a 1 / 4 electric wheel vehicle two-degree-of-freedom linear vibration model is established as follows:

[0097]

[0098]

[0099] Among them, m s is 1 / 4 body mass, m t is the wheel mass, m e is the mass of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com