A multi-flow heat exchanger, a split flow adjustment method and a refrigerant circulation system

A heat exchanger and multi-flow path technology, which is applied in the field of refrigerant circulation system, can solve the problems that the heat exchange area of the evaporator cannot be fully utilized, there are too many refrigerants, and the manufacturing cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

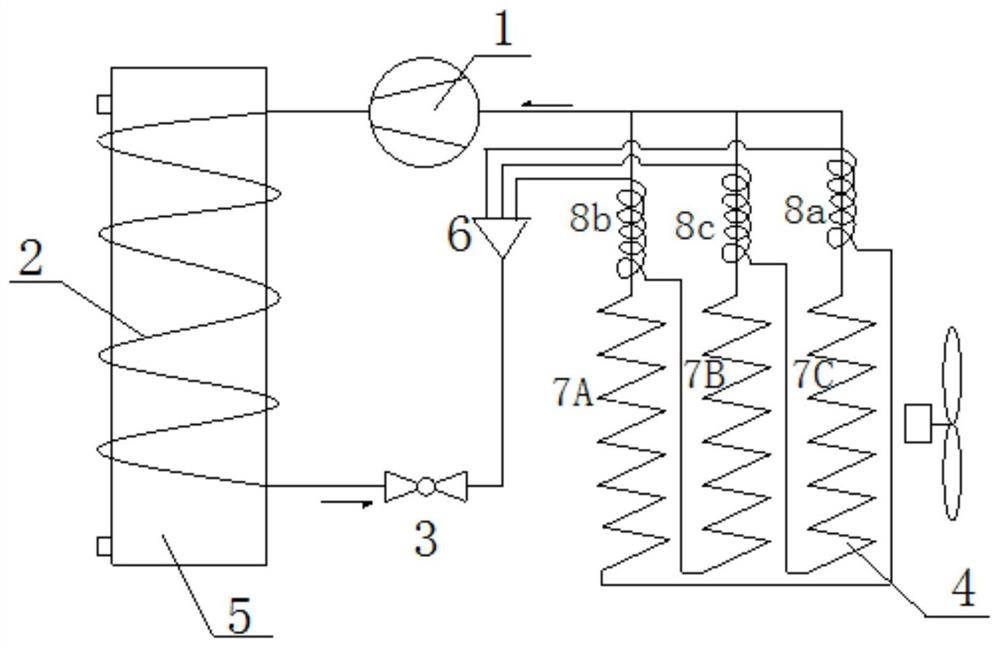

[0025] Such as figure 1 As shown, a refrigerant circulation system provided by the present invention is a heat pump water heater system, including a working medium circulation circuit composed of a compressor 1 , a condenser 2 , a main throttling element 3 and an evaporator 4 . Among them, the main throttling element 3 adopts an electronic expansion valve, which is a first-stage throttling element. The condenser 2 is installed in a water storage tank 5 to exchange heat with the water in the water storage tank 5. The heat of the high-temperature refrigerant working medium heats the water in the water storage tank 5 for use by users. The refrigerant circulation system can also be an air conditioner, refrigerator, freezer and other refrigeration equipment, and only the compressor 1, the condenser 2, the main throttling element 3 and the evaporator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com