Fuel cell heat dissipation system for high-power power station and control method

A fuel cell and heat dissipation system technology, which is applied in the field of power stations, can solve the problems of low heat dissipation efficiency of fuel cell systems, achieve the effects of solving uneven distribution, improving heat exchange efficiency, and better performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

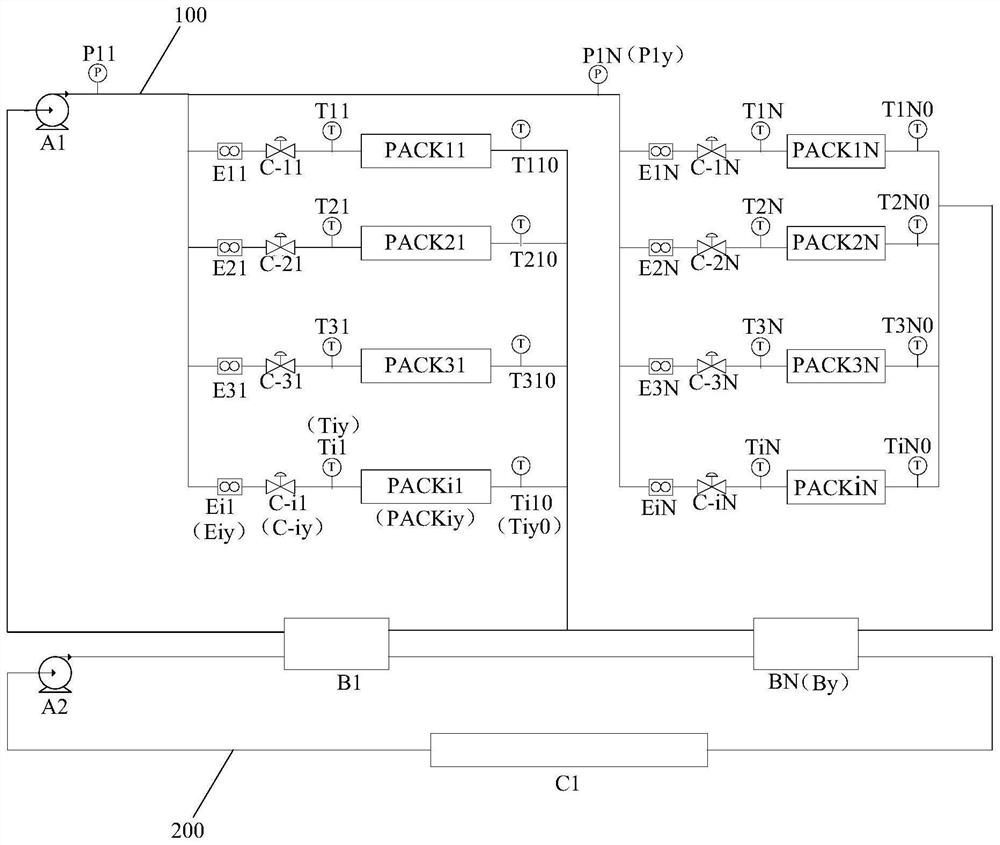

[0024] See figure 1 , an embodiment of the present invention provides a fuel cell heat dissipation system for a high-power power station, including a coolant circuit 100 and a heat dissipation circuit 200 .

[0025] The coolant circuit 100 includes a first water pump A1, N fuel cell modules and N heat exchangers By, and the N fuel cell modules include the first fuel cell module...the Nth fuel cell module, N The heat exchangers By include the first heat exchanger B1 ... the Nth heat exchanger BN, N is a natural number and greater than 1 (N is the number of fuel cell modules), the fuel cell module and the heat exchanger Heaters By are in one-to-one correspondence, the first water pump A1 is connected in series with the first fuel cell module and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com