Preparation method of nano ferric oxide doped styrene-divinylbenzene copolymer hydrophobic catalyst carrier

A technology of triiron tetroxide and divinylbenzene, which is used in catalyst carriers, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of small catalyst particle size, poor catalytic stability, Problems such as poor hydrophobic stability, to achieve the effect of easy industrial production, mild reaction conditions and high degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

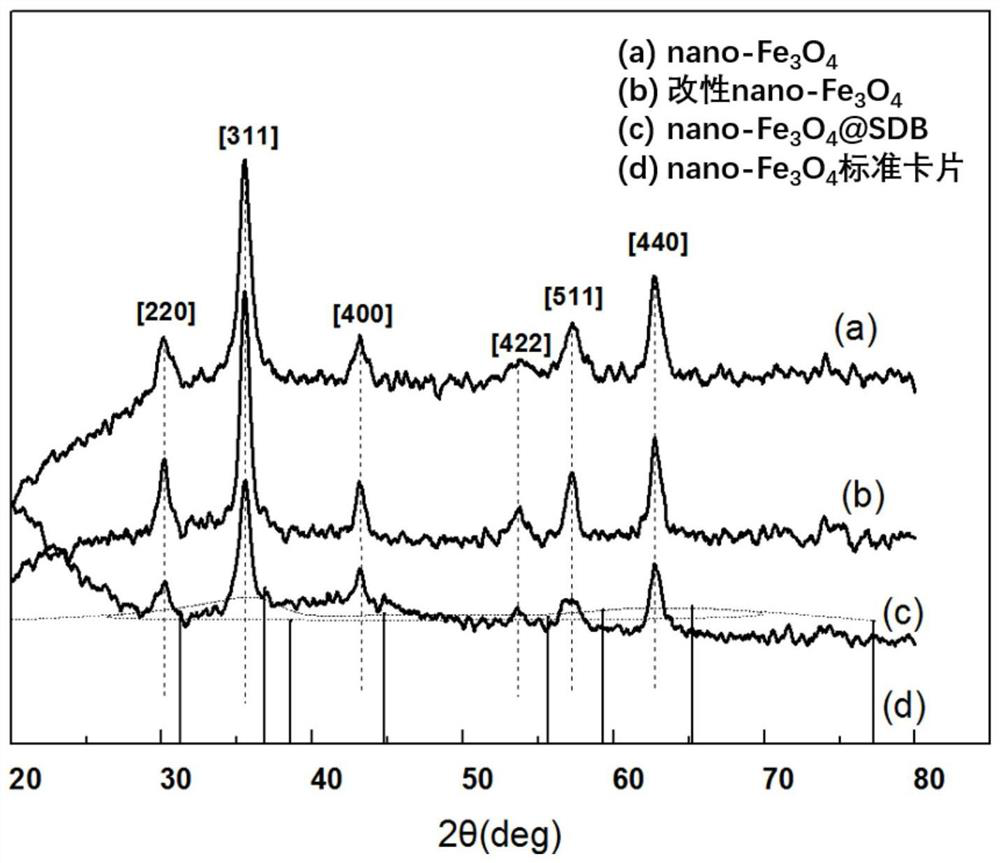

Image

Examples

Embodiment 1

[0049] A method for preparing a nanometer iron ferric oxide doped styrene-divinylbenzene copolymer hydrophobic catalyst carrier, the steps are:

[0050] a, preparation of nano ferric oxide ion:

[0051] Add 100g of deionized water, 100g of absolute ethanol, and 40°C constant temperature water bath to preheat and stir in the reactor (three-necked flask), take 15g of ferric chloride and 10g of ferric chloride, add 50g of deionized water to dissolve each, and pour them in turn Put it into the reactor, quickly pour 8g of 25%wt ammonia water under the protection of nitrogen (that is, 25% of the mass percentage of ammonia water, the same below), adjust the rotation speed to 400rpm, react for 1.5h, add 2g of silane coupling agent, and heat to 60°C , reacted to 2h, centrifuged at 550rpm to precipitate, washed the precipitate with deionized water and absolute ethanol in sequence, and dried in vacuum at 70°C for 12h;

[0052] b. Preparation of nano ferric oxide doped styrene-divinylben...

Embodiment 2

[0055] A method for preparing a nanometer iron ferric oxide doped styrene-divinylbenzene copolymer hydrophobic catalyst carrier, the steps are:

[0056] a, preparation of nano ferric oxide ion:

[0057] Add 100g of deionized water, 100g of absolute ethanol, and a constant temperature water bath at 50°C to preheat and stir in the reactor (three-necked flask), take 15g of ferric chloride and 10g of ferric chloride, add 50g of deionized water to dissolve each, and pour them in turn In the reactor, quickly pour 6g of 25%wt ammonia water under the protection of nitrogen, adjust the rotation speed to 450rpm, react for 1.5h, add 3g of silane coupling agent, heat to 60°C, react for 2h, centrifuge at 550rpm / min, and precipitate Wash with deionized water and absolute ethanol once, and vacuum dry at 70°C for 12 hours;

[0058] b. Preparation of nano ferric oxide doped styrene-divinylbenzene copolymer hydrophobic catalyst support:

[0059] Add 400g of deionized water, 5g of polyvinyl al...

Embodiment 3

[0061] A method for preparing a nanometer iron ferric oxide doped styrene-divinylbenzene copolymer hydrophobic catalyst carrier, the steps are:

[0062] a, preparation of nano ferric oxide ion:

[0063] Add 150g of deionized water and 150g of absolute ethanol to the reactor (three-necked flask), preheat and stir with a 40°C constant temperature water bath, take 15g of ferric chloride and 10g of ferric chloride, add 50g of deionized water to dissolve each, and then Pour into the reactor, quickly pour 5g of 25%wt ammonia water under the protection of nitrogen, adjust the rotation speed at 500rpm / min, react for 1.5h, add 4g of silane coupling agent, heat to 60°C, react for 2h, centrifuge at 550rpm / min to precipitate , the precipitate was washed with deionized water and absolute ethanol in sequence, and dried in vacuum at 65°C for 24h;

[0064] b. Preparation of nano ferric oxide doped styrene-divinylbenzene copolymer hydrophobic catalyst carrier:

[0065] Add 400g of deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com