Concrete reinforcing agent and preparation method thereof

A technology of concrete reinforcing agent and water reducing agent, applied in the field of concrete, can solve the problems affecting the quality and strength of concrete, and achieve the effects of improving comprehensive performance, enhancing strength and increasing curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

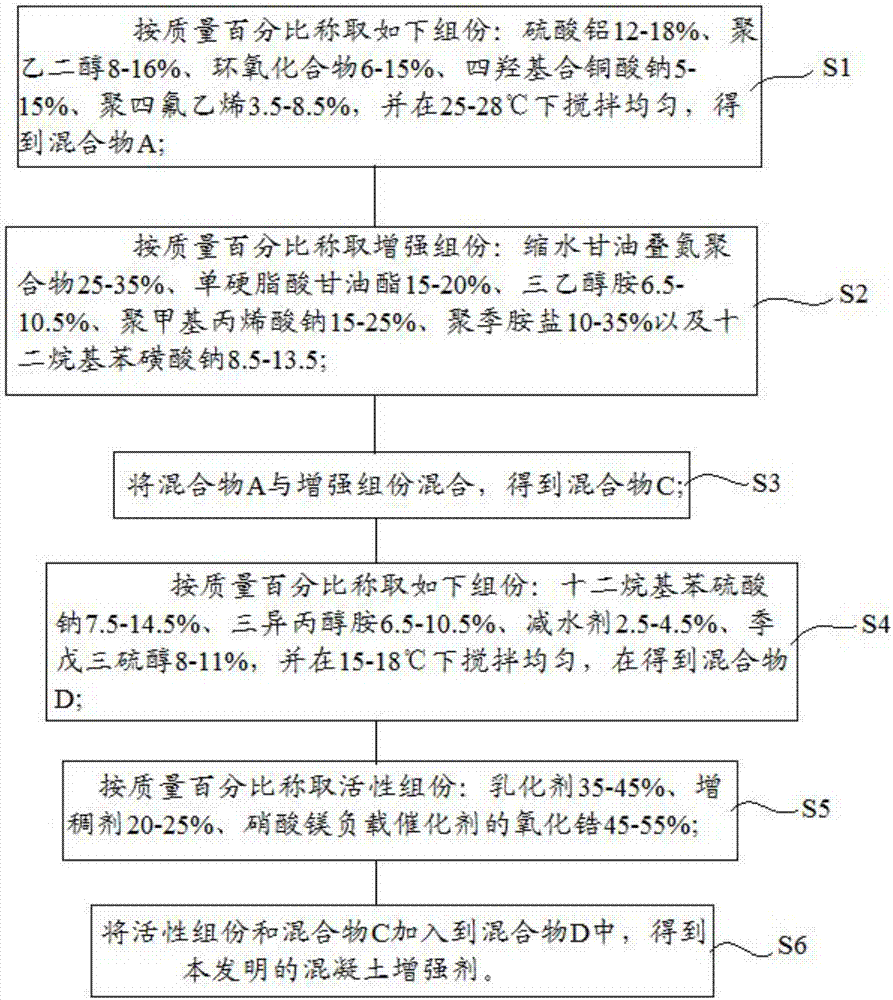

Embodiment 1

[0038] Weigh the following components by mass percentage: 12% aluminum sulfate, 8% polyethylene glycol, 6% epoxy compound, 5% sodium tetrahydroxycuprate, 3.5% polytetrafluoroethylene, and stir evenly at 25°C , to obtain mixture A. Weigh the reinforcement components by mass percentage: 35% glycidyl azide polymer, 20% glyceryl monostearate, 10.5% triethanolamine, 25% sodium polymethacrylate, 10% polyquaternary ammonium salt and dodecane Sodium phenyl sulfonate 8.5-13.5. Mixture A is mixed with the reinforcing component to obtain Mixture C. Weigh the following components by mass percentage: sodium dodecylbenzenesulfate 7.5%, triisopropanolamine 10.5%, water reducer 2.5%, pentaerythritthiol 11%, and stir evenly at 15-18°C , to obtain mixture D. The active components are weighed by mass percentage: 45% of emulsifier, 25% of thickener, and 45% of zirconia supported by magnesium nitrate catalyst. The active component and the mixture C are added to the mixture D to obtain the conc...

Embodiment 2

[0040] Weigh the following components by mass percentage: 18% of aluminum sulfate, 16% of polyethylene glycol, 6-15% of epoxy compound, 5% of sodium tetrahydroxycuprate, 8.5% of polytetrafluoroethylene, and at 25-28 Stir evenly at ℃ to obtain mixture A; weigh the reinforcing components by mass percentage: glycidyl azide polymer 25%, glyceryl monostearate 15%, triethanolamine 6.5%, sodium polymethacrylate 25%, poly quaternary ammonium salt 35% and sodium dodecylbenzenesulfonate 13.5%; mix mixture A with the reinforcing component to obtain mixture C; weigh the following components by mass percentage: sodium dodecylbenzenesulfate 14.5%, triiso 6.5% propanolamine, 2.5% water reducer, 8% pentaerythrthiol, and stir evenly at 18°C to obtain mixture D; weigh active components by mass percentage: emulsifier 35%, thickener 20%, 55% of zirconia supported by magnesium nitrate catalyst; adding the active component and mixture C to the mixture D to obtain the concrete reinforcing agent of...

Embodiment 3

[0042] Weigh the following components by mass percentage: aluminum sulfate 14%, polyethylene glycol 15%, epoxy compound 12%, sodium tetrahydroxycuprate 5-15%, polytetrafluoroethylene 8.5%, and at 28 ℃ Stir evenly to obtain mixture A; weigh the reinforcement components by mass percentage: 27% glycidyl azide polymer, 18% glyceryl monostearate, 8.5% triethanolamine, 25% sodium polymethacrylate, polyquaternary ammonium Salt 28% and sodium dodecylbenzenesulfonate 10.5%; mixture A is mixed with the reinforcing component to obtain mixture C; the following components are weighed by mass percentage: sodium dodecylbenzenesulfonate 2.5%, triisopropanol 8.5% amine, 3.5% water reducer, 10% pentaerythrthiol, and stir evenly at 16°C to obtain mixture D; weigh active components by mass percentage: emulsifier 40%, thickener 22% , 48% of zirconia supported by magnesium nitrate catalyst; the active component and the mixture C are added to the mixture D to obtain the concrete reinforcing agent of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com