Semi-finished product removing device of doubling machine

A semi-finished product and removal technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of limiting the use range of woven cladding, and achieve the effect of convenient and fast transfer, improved efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

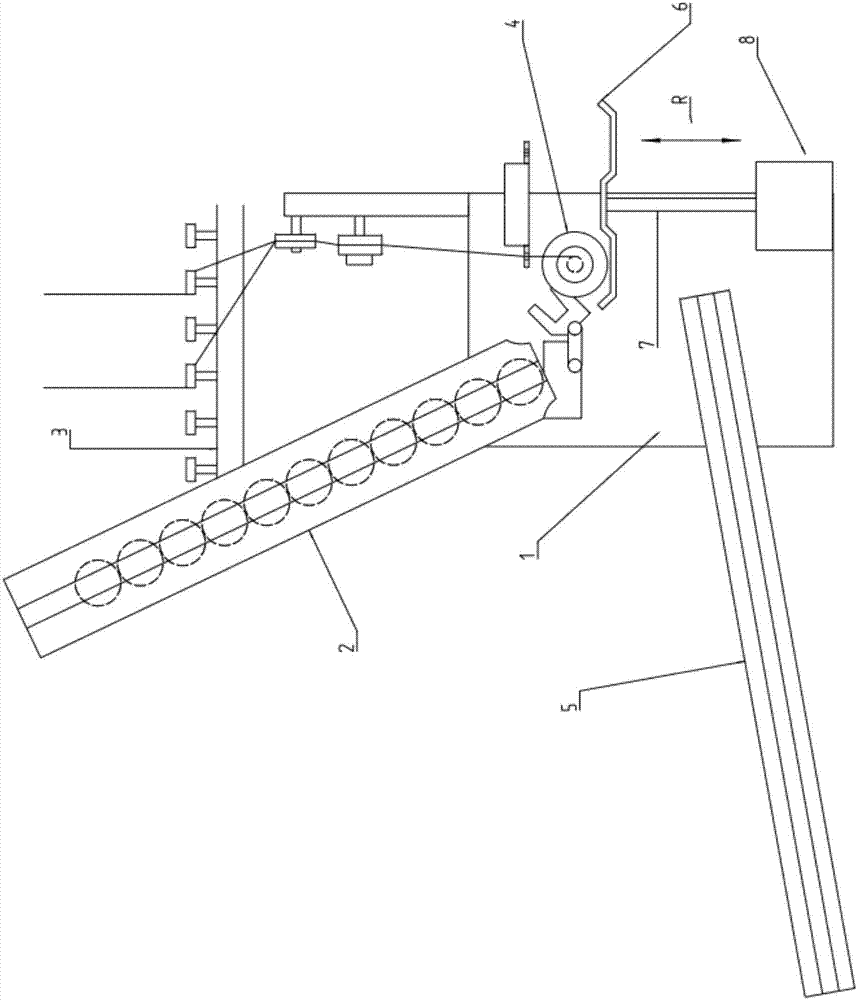

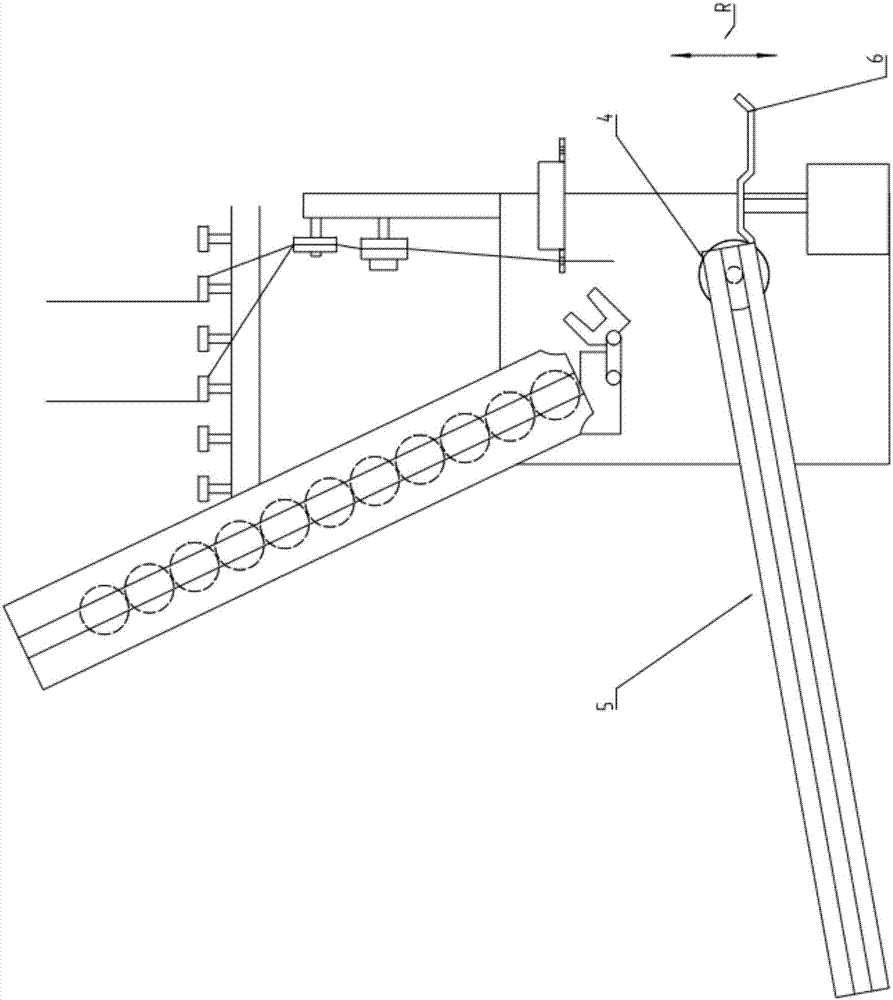

[0014] Such as Figure 1-2 Shown is an embodiment of the semi-finished product removal device of the doubling machine according to the present invention.

[0015] The semi-finished product removal device of the doubling machine includes machine 1, bobbin supply rack 2, doubling rack 3, bobbin 4, removal slot 5, bracket 6, slide bar 7, and actuator 8, of which the front of machine 1 is close to one end The position is provided with a bobbin supply rack 2, and the bobbin supply rack 2 accommodates the bobbin 4 to be wound, and the middle part of the front of the machine 1 is provided with a rotor for removably installing and driving the bobbin 4 to rotate, and a removal slot 5 is arranged under the rotor , a bracket 6, a slide bar 7 and an actuator 8 are arranged between the bobbin supply frame 2 and the removal slot 5, wherein the actuator 8 is configured to drive the slide bar 7 to reciprocate along the longitudinal moving direction R, and the slide bar 7 One end is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com