GC-MS method for detecting dimethyl sulphate content in industrial waste liquid

A technology of dimethyl sulfate and GC-MS, which is applied in the field of chemical analysis, can solve the problems of instability in contact with water, lack of UV-absorbing functional groups, low content of dimethyl sulfate, etc., and achieve the effect of accurate sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Instruments and Conditions:

[0033] Gas chromatography mass spectrometry: Agilent 7890B GC, 5977A MS detector

[0034] Chromatographic column: Agilent DB-5MS (30m×0.25mm ID×0.25μm)

[0035] Ion source: Electron ionization source

[0036] Carrier Gas: Helium

[0038] Mode: Constant Current

[0039] Flow rate: 0.65ml / min

[0040] Split ratio: 10:1

[0041] Injection volume: 1μL

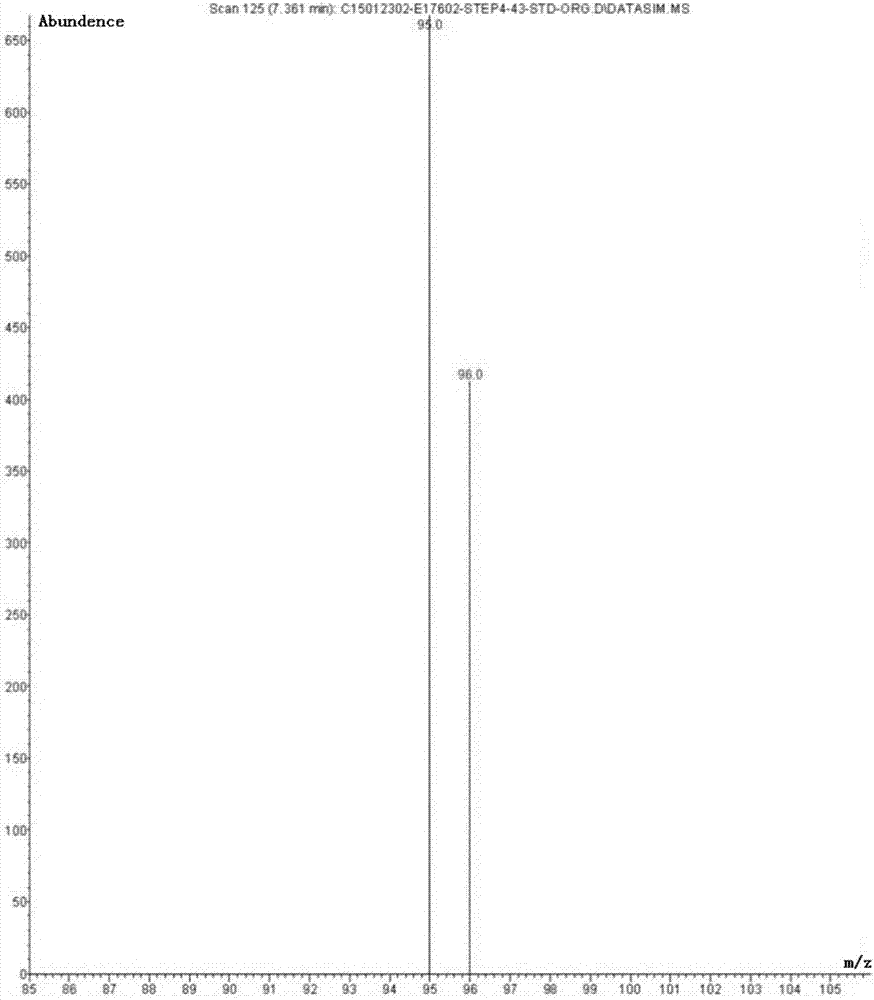

[0042] Extracted molecular weight: 95 and 96;

[0043] Injection port temperature: 200°C

[0044] The column temperature gradient is as follows:

[0045] Ramp

temperature

-

50℃

0min

10℃ / min

120℃

2min

30℃ / min

240℃

5min

[0046] Experimental steps:

[0047] Diluent: Acetonitrile.

[0048] Standard dimethyl sulfate solution: Accurately weigh about 50mg of dimethyl sulfate into a 10mL volumetric flask containing 2ml of diluent, add diluent to constant volume and shake well, accurately ...

Embodiment 2

[0052] Instruments and Conditions:

[0053] Gas chromatography mass spectrometry: Agilent 7890B GC, 5977A MS detector

[0054] Chromatographic column: Agilent DB-1 (30m×0.25mm ID×0.25μm)

[0055] Ion source: Electron ionization source

[0056] Carrier Gas: Helium

[0058] Mode: Constant Current

[0059] Flow rate: 0.65ml / min

[0060] Split ratio: 10:1

[0061] Injection volume: 1μL

[0062] Extracted molecular weight: 95 and 96;

[0063] Injection port temperature: 200°C

[0064] The column temperature gradient is as follows:

[0065] Ramp

temperature

-

50℃

0min

10℃ / min

120℃

2min

30℃ / min

240℃

5min

[0066] Experimental steps:

[0067] Diluent: Acetonitrile.

[0068] Standard dimethyl sulfate solution: Accurately weigh about 50mg of dimethyl sulfate into a 10mL volumetric flask containing 2ml of diluent, add diluent to constant volume and shake well, accurately pi...

Embodiment 3

[0071] Example 3: Methodological Validation

[0072] 1. Exclusive experiment

[0073] Get dimethyl sulfate reference substance appropriate amount, according to the method for example 2, prepare standard dimethyl sulfate solution, and this solution adopts gas chromatography mass spectrometry to detect and analyze according to the method for example 2.

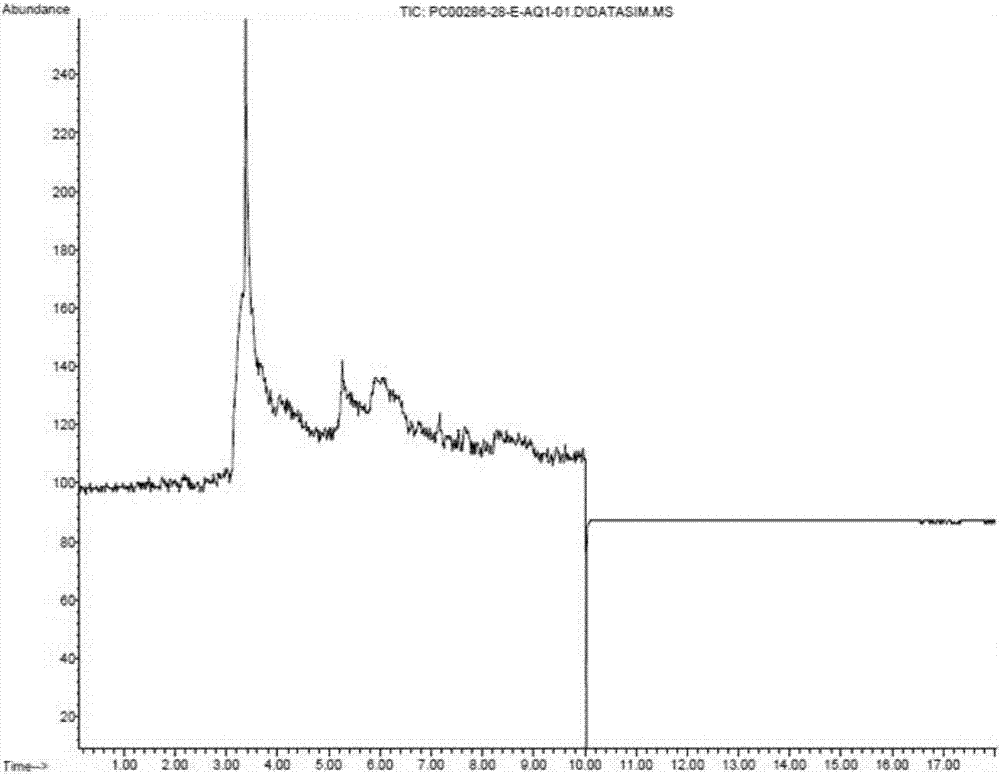

[0074] The experimental results show that at the retention time of dimethyl sulfate, there is no interference from the blank; the tailing factor of dimethyl sulfate is 0.93, and the peak shape is good; the separation between dimethyl sulfate and its adjacent peaks is 6.65, which is good. see details Figure 6 .

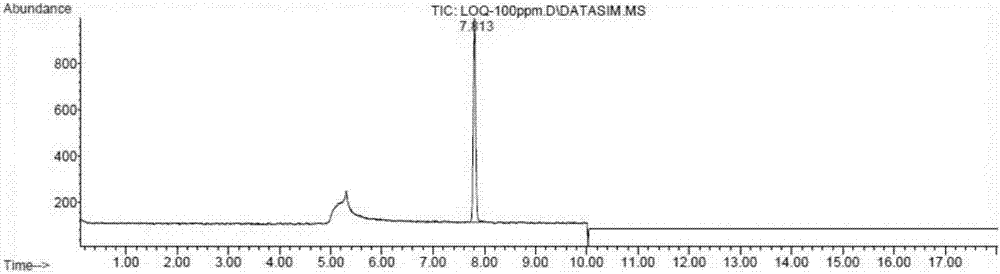

[0075] 2. Quantitation limit experiment

[0076] Get an appropriate amount of dimethyl sulfate reference substance, according to the method for example 2, prepare standard dimethyl sulfate solution, accurately pipette 5mL of the above-mentioned solution to a 10mL volumetric flask, add diluent to constant volume and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com