Device and method for separating gas from pressurized liquid

A technology for separating gas and liquid, applied in separation methods, liquid degassing, auxiliary substance liquid degassing, etc., can solve the problem of inability to accurately quantify the content of dissolved gas components, the inability to provide effective support for the subsequent treatment of gas components, and the inability to Gas quantification and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

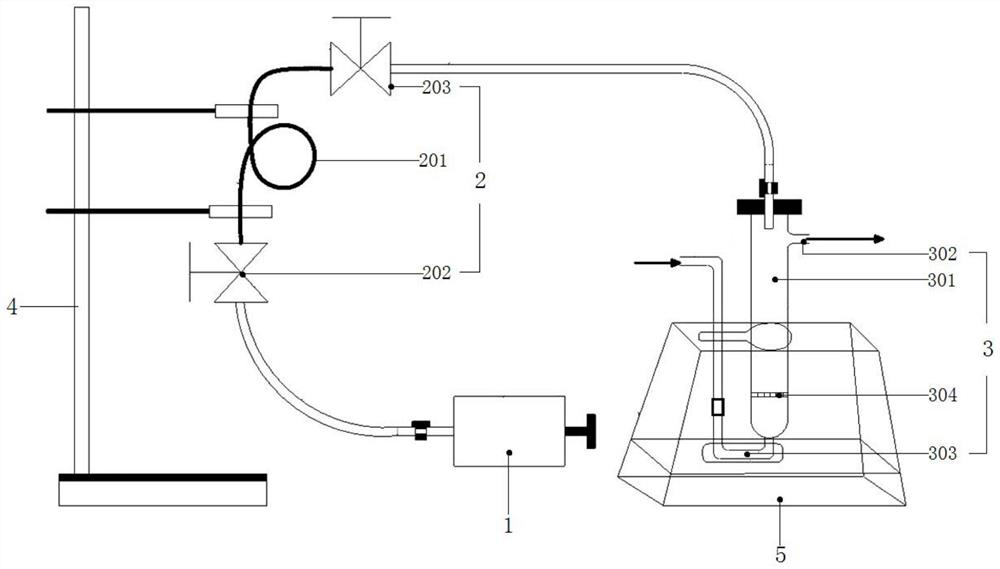

[0033] On the one hand, the embodiment of the present invention provides a device for separating gas from pressurized liquid, such as the attached figure 1 As shown, the device includes: an injector 1, a sampler 2 and a stripper 3 connected in sequence through a connecting pipeline.

[0034] Wherein, the sampler 2 includes: a quantitative sampling tube 201 , an inlet valve 202 and an outlet valve 203 respectively arranged at both ends of the quantitative sampling tube 201 .

[0035] Stripper 3 comprises: the stripping pipe 301 that is communicated with connecting pipeline, the outlet pipe 302 that communicates with the stripping pipe 301 top, the inlet pipe 303 that communicates with the bottom of stripping pipe 301, and be arranged on the stripping pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com