Coke oven raw gas heat continuous recovery system

A recovery system and waste gas technology, which are applied in the heating, coke oven, energy input and other directions of coke ovens, can solve the problem of water leakage from the coke oven riser pipe to the coke oven carbonization chamber, the complex composition of coke oven waste gas, and the impact on the safe production of coke ovens. and other problems, to achieve the effect of improving the cycle utilization rate, speed and utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

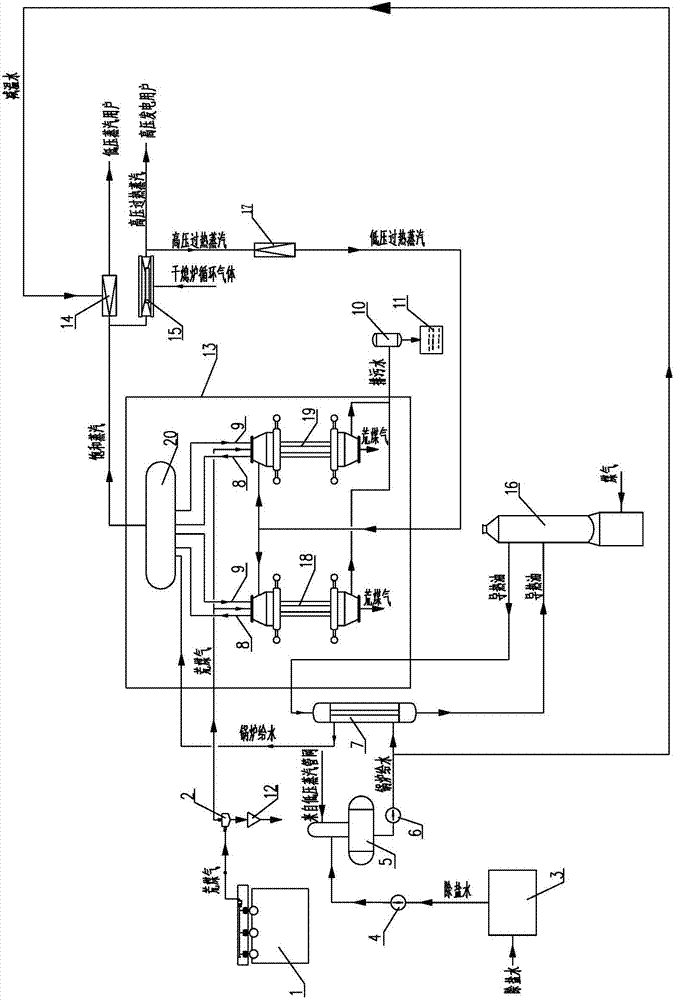

[0021] Such as figure 1 As shown, a coke oven raw gas heat recovery system without interruption according to the present invention includes a high-temperature dust collector 2, a waste heat boiler 13, a low-temperature heat exchanger 7, a deaerator 5, a desalinated water tank 3, a heating furnace 16, a Temperature and decompression device 14, steam superheater 15 and decompression device 17; described waste heat boiler 13 is composed of steam drum 20 and steam heat exchanger A 18 connected with steam drum 20 through rising pipe 8 and down pipe 9 respectively, steam exchanger Heater B 19; the raw gas input end of the high temperature dust collector 2 is connected to the gas collecting pipe of the coke oven 1, and the raw gas output end of the high temperature dust collector 2 is connected to the steam heat exchanger A 18 and the steam heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com