Molding machine rotating valve device with backflow protecting function

A protection function and molding machine technology, applied to valve devices, cocks including cut-off devices, valve details, etc., can solve problems such as unstable shaping pressure, tire damage, gas path disorder, etc., achieve low cost of transformation, eliminate equipment Failure, structure design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

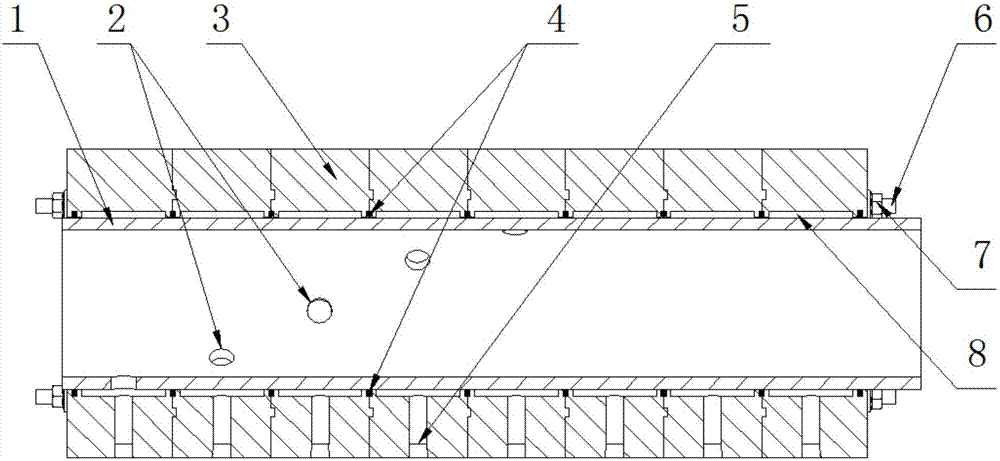

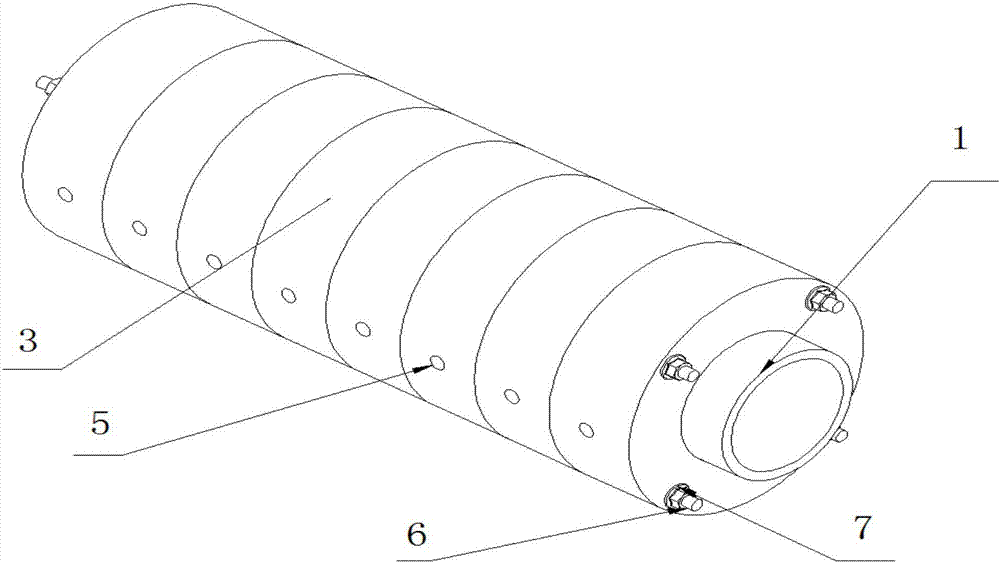

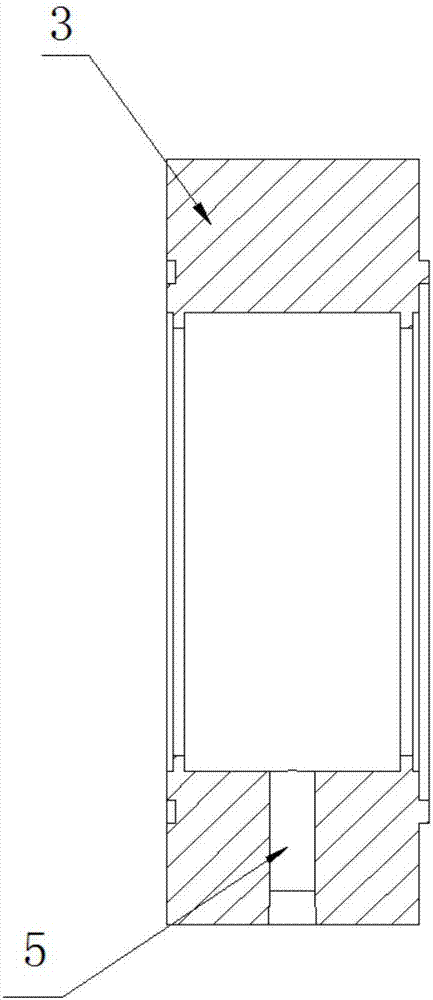

[0022] like Figure 1-6 As shown, a molding machine rotary valve device with the function of cross gas protection includes a plurality of rotary valves 11 arranged side by side installed on the main shaft 1, and between each rotary valve and the main shaft, there is a phase close to the adjacent rotary valve. A sealing ring 4 is provided at the joint, so that each independent rotary valve is provided with a sealing ring, so that when a certain sealing ring 4 fails, the gas leak can be directly discharged into the atmosphere, and the adjacent two air channels 8 There will be no cross-gas failure.

[0023] A first cavity 12 is independently isolated between the two sealing rings 4, and a step 13 is provided near the main shaft end at the junction of the adjacent rotary valves, and the junction of the step 13 and the adjacent rotary valve is formed There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com