Activated carbon supporting ferric oxyhydroxide composite adsorbent, and preparation and application thereof

An iron oxyhydroxide and composite adsorption technology, which is applied in adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of low adsorption efficiency of activated carbon, expensive materials, poor removal effect, etc. Recycling, high load rate and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of activated carbon loaded iron oxyhydroxide composite adsorbent, comprising the following steps:

[0035] (1) Ultrasonicate 30g of activated carbon in 1L of 60wt% acetic acid solution (power 200W, frequency 100KHz, time 30min), seal, magnetically stir for 24h, change the water to boil, wash, change the water to boil, repeat this until the filtrate after the activated carbon is washed Clear and transparent, dry, and calcined at 500°C for 24 hours to obtain pretreated activated carbon; the boiling time for each boiling is 10 minutes; the drying temperature is 80°C;

[0036] (2) Mix 3g of pretreated activated carbon with 50mL of 0.001mol / L FeCl 3 The solution was stirred for 15 minutes, sealed, soaked and reacted at 100° C. for 10 hours, washed, and dried to constant weight (the drying temperature was 70° C.) to obtain an activated carbon-loaded iron oxyhydroxide composite adsorbent. The loading rate of iron oxyhydroxide in this embodiment is 2.03%. ...

Embodiment 2

[0038] A preparation method of activated carbon loaded iron oxyhydroxide composite adsorbent, comprising the following steps:

[0039] (1) Ultrasonicate 30g of activated carbon in 1L of 60wt% acetic acid solution (power 200W, frequency 100KHz, time 30min), seal, magnetically stir for 24h, change the water to boil, wash, change the water to boil, repeat this until the filtrate after the activated carbon is washed Clear and transparent, dry, and calcined at a high temperature of 500°C for 24 hours to obtain pretreated activated carbon; each time of boiling in the boiling is 15min; the drying temperature is 70°C;

[0040] (2) Mix 3g of pretreated activated carbon with 50mL of 0.01mol / L FeCl 3 The solution was stirred for 15 minutes, sealed, soaked and reacted at 140° C. for 15 hours, washed, and dried to constant weight (the drying temperature was 70° C.) to obtain an activated carbon-loaded iron oxyhydroxide composite adsorbent.

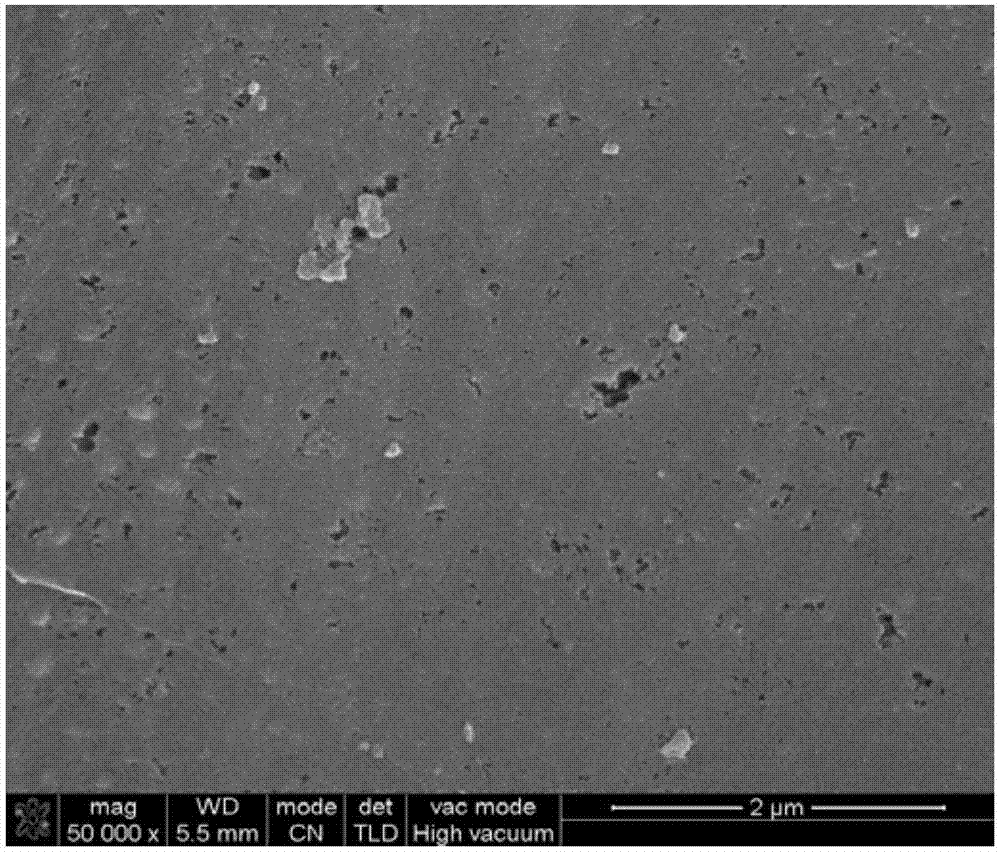

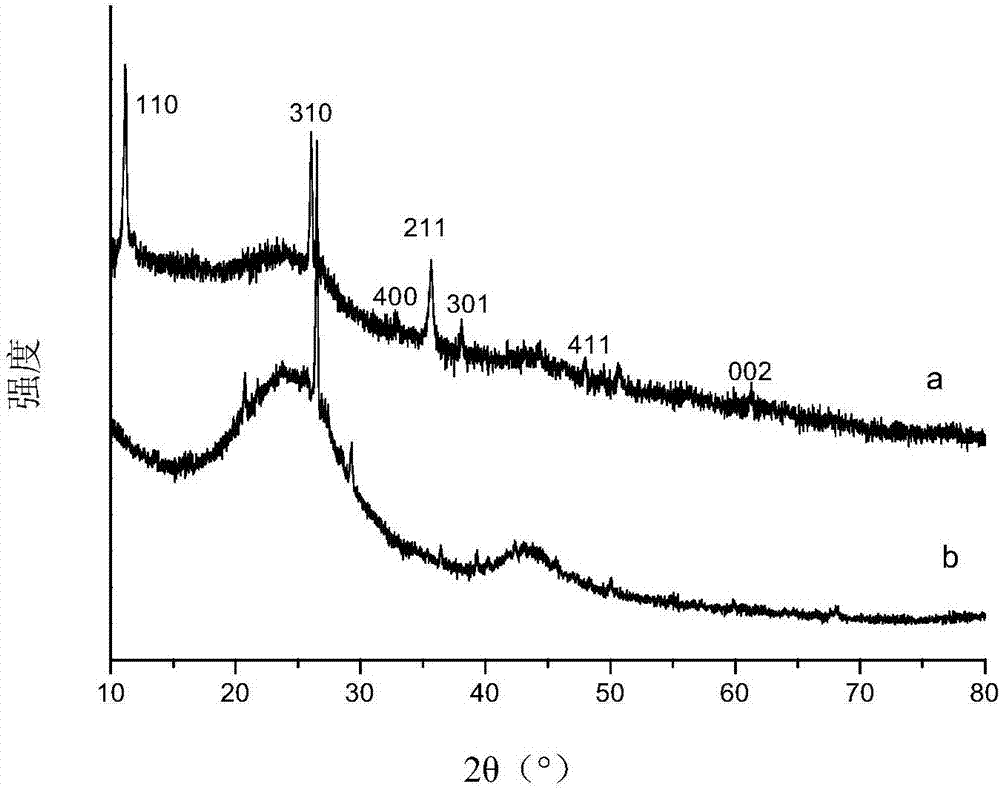

[0041] The SEM image of the activated carbon-lo...

Embodiment 3

[0045] A preparation method of activated carbon loaded iron oxyhydroxide composite adsorbent, comprising the following steps:

[0046] (1) Ultrasonicate 30g of activated carbon in 1L of 60wt% acetic acid solution (power 200W, frequency 100KHz, time 30min), seal, magnetically stir for 24h, change the water to boil, wash, change the water to boil, repeat this until the filtrate after the activated carbon is washed Clear and transparent, dry, and calcined at a high temperature of 500°C for 24h to obtain pretreated activated carbon; each time of boiling in the boiling is 15min; the drying temperature is 80°C;

[0047] (2) Mix 3g of pretreated activated carbon with 50mL of 0.02mol / L FeCl 3 The solution was stirred for 15 minutes, sealed, soaked and reacted at 150° C. for 20 hours, washed, and dried to constant weight (the drying temperature was 70° C.) to obtain an activated carbon-loaded iron oxyhydroxide composite adsorbent.

[0048] The loading rate of iron oxyhydroxide in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com