Elastic castor assembly applied to household movable door window

An elastic and caster technology, applied in door/window accessories, wing fan parts, wing fan suspension devices, etc., can solve the problems of high cost of metal materials, reduced production efficiency, not smooth enough pushing and pulling, etc., and achieves convenient and fast installation. Improve safety and smooth push-pull effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

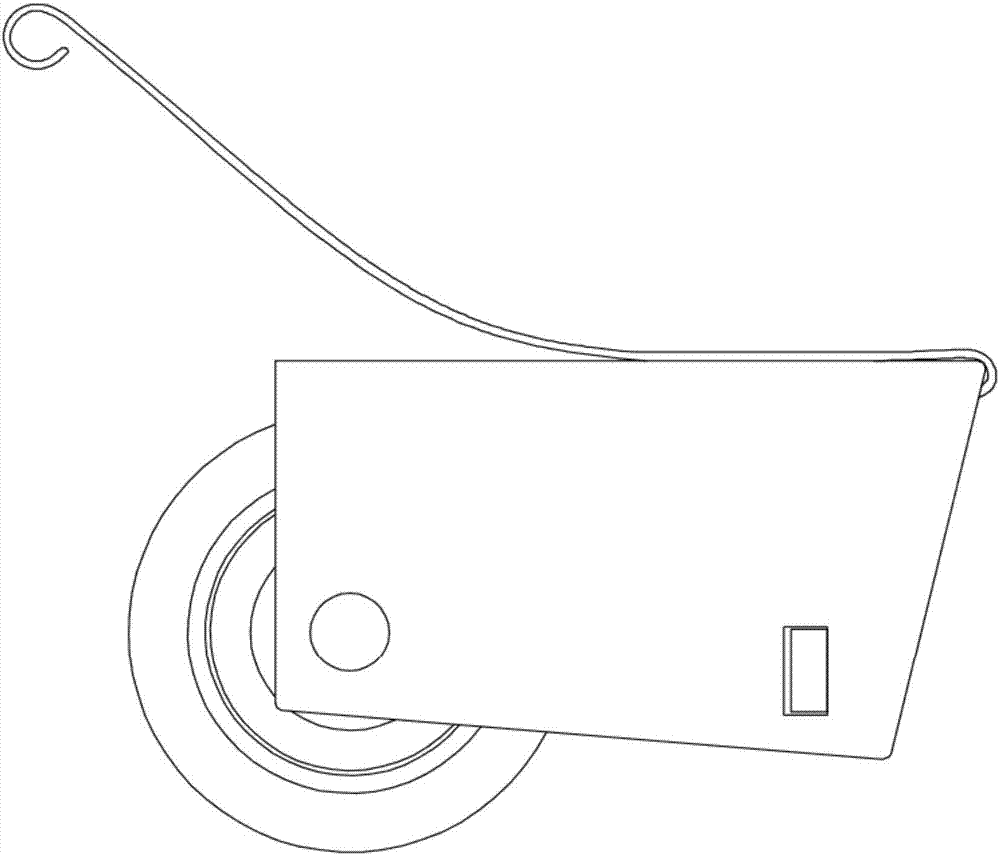

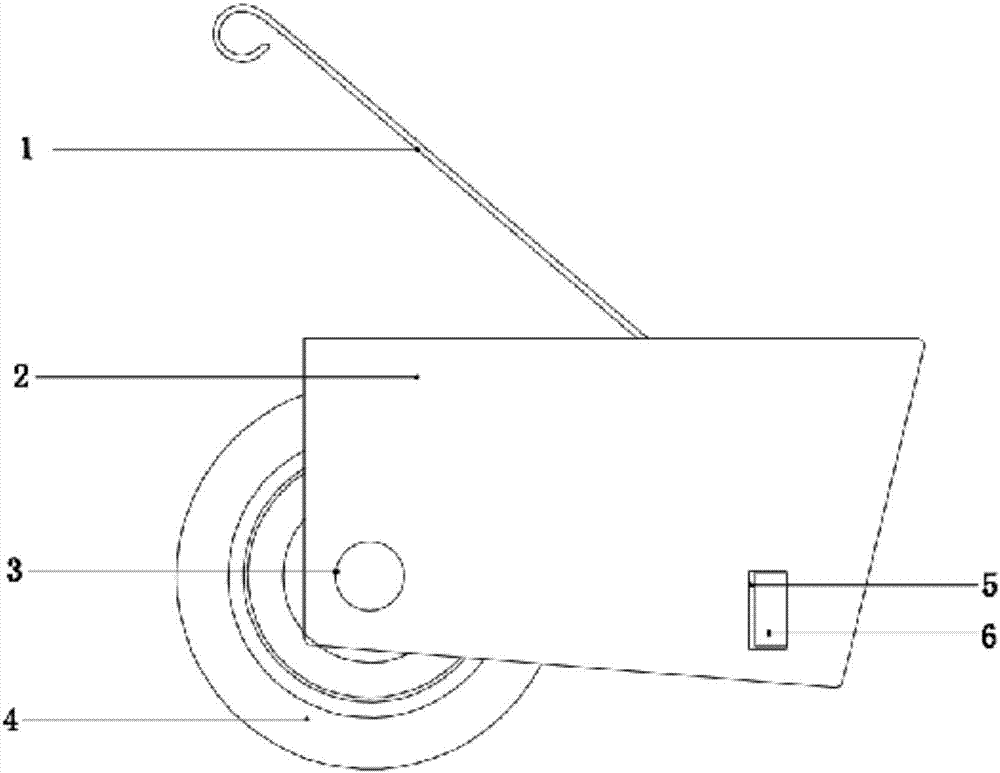

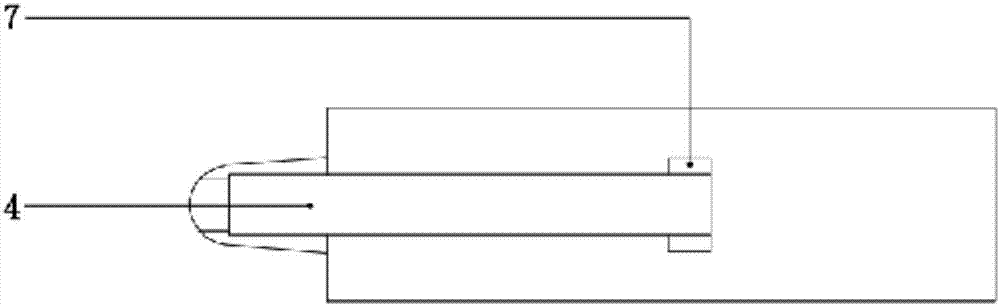

[0030] see Figure 2-Figure 7 , the specific embodiment adopts the following technical solutions: an elastic caster assembly applied to home moving doors and windows, which includes a self-locking lever shrapnel 1, a non-metallic shell 2, a pulley bearing hole 3, a pulley 4, a positioning piece opening 5, a positioning Sheet 6, shrapnel insertion port 7, bearing 8, thimble insertion hole 9, pulley groove 10 and self-locking fixing buckle 11, the lower part of the non-metallic shell 2 is provided with a pulley groove 10, and the front ends of both sides of the pulley groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com