High-temperature magnesium oxychloride thermosetting resin gel system as well as solidified body and preparation method of system

A magnesium oxychloride thermosetting and epoxy resin curing technology, applied in the field of oil and gas well cementing, can solve the problems of inability to achieve performance control, failure to achieve bonding, etc., achieve controllable curing time, solve easily damaged, and meet cementing requirements. The effect of construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

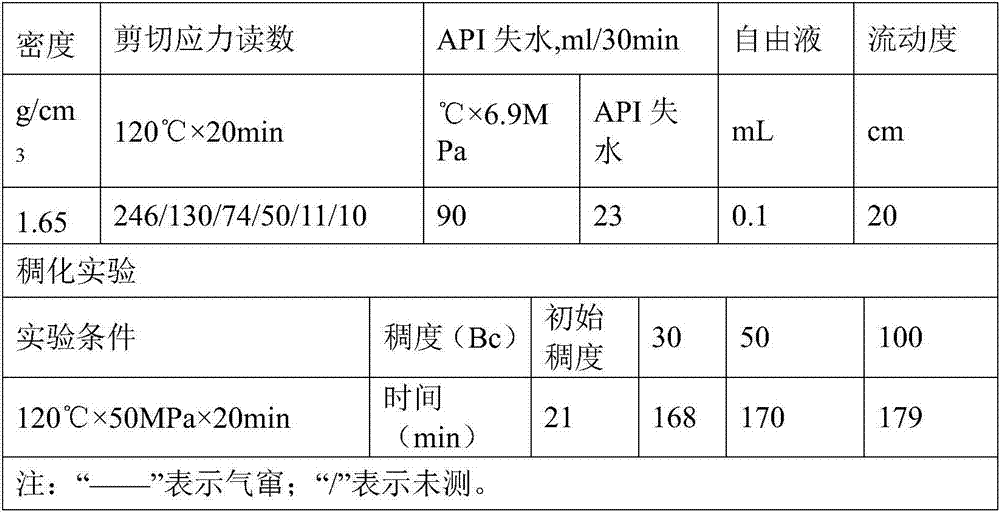

Embodiment 1

[0018] (1) Weigh 300g of light-burned magnesia (MgO, Hebei Xingtai Meishen Chemical Co., Ltd.), 300g of magnesium chloride (MgCl 2 , Shandong Zibo Huayan Chemical Co., Ltd.), polyvinyl alcohol fluid loss reducer 6g (FSAM, Shandong Dezhou Continental Shelf Auxiliary Factory), polyphosphate medium temperature coagulant 30g (NP2, Shandong Dezhou Continental Shelf Auxiliary Factory), EDTA salt chelating agent 15g (NP3, Shandong Dezhou Continental Shelf Auxiliary Factory, EDTA calcium salt), silicone oil defoamer 1.5g (DZX, Shandong Dezhou Continental Shelf Auxiliary Factory), glycidylamine type epoxy resin emulsion 60g (RS, Shandong Dezhou Continental Shelf Auxiliary Factory), epoxy resin amine curing agent 30g (RSC, Shandong Dezhou Continental Shelf Auxiliary Factory), fresh water 135g.

[0019] (2) The mixture of magnesium chloride, glycidyl amine type epoxy resin emulsion, epoxy resin amine curing agent, silicone oil defoamer, polyphosphate medium temperature coagulant and EDTA...

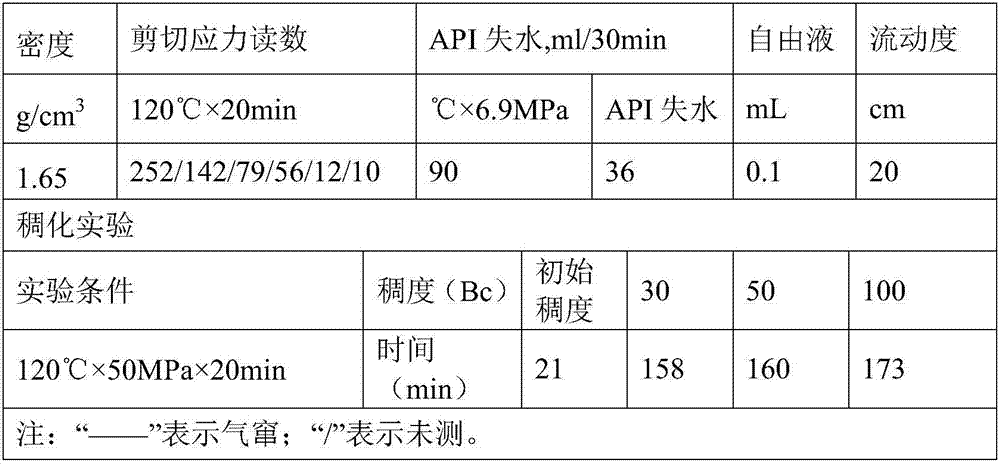

Embodiment 2~5

[0030] Change the amount of polyphosphate medium temperature coagulant to 15g, 24g, 30g, 45g respectively, and at the same time change the amount of EDTA salt chelating agent to 9g, 9g, 9g, 15g respectively. The amount and steps of other components All are the same as steps (1) to (3) of Example 1 to prepare a high-temperature magnesium oxychloride thermosetting resin gelling system.

[0031] The high-temperature magnesium oxychloride thermosetting resin gelling system obtained in Examples 2-5 was tested for thickening time according to the main performance test method of GB / T19139-2012 cement slurry, and the results are shown in Table 3.

[0032] Table 3 Thickening time of high temperature magnesium oxychloride thermosetting resin gelling system with different dosage of coagulation regulator

[0033] formula

[0034] It can be seen from Table 3 that with the increase of the amount of coagulation regulator, the thickening time of the high-temperature magnesium oxychl...

Embodiment 6~8

[0036] Change the consumption of glycidylamine type epoxy resin emulsion into 15g, 30g, 45g respectively, the consumption and steps of other components are all identical with the step (1)~(3) of embodiment 1, make high temperature magnesium oxychloride heat Solid resin gelling system.

[0037] The elastic modulus of the high-temperature magnesium oxychloride thermosetting resin gelling system in Example 1 and Examples 6-8 was tested according to the main performance test method of Q / SH 0275.1-2009 cement slurry. The results are shown in Table 4 below.

[0038] Table 4 Cured elastic modulus of high temperature magnesium oxychloride thermosetting resin gelling system with different epoxy resin additions

[0039] formula

[0040] It can be seen from Table 4 that the indoor test shows that the cured body of the high-temperature magnesium oxychloride thermosetting resin gelling system has a lower elastic modulus, and as the amount of epoxy resin increases, the elastic mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com