Adsorption, aeration and nanofiltration combined technology for arsenic-containing water treatment and special device for technology

A combined process and special device technology, applied in the field of water treatment, can solve problems such as excessive arsenic content, achieve the effects of slowing down the process of membrane fouling, improving removal efficiency, and high retention efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

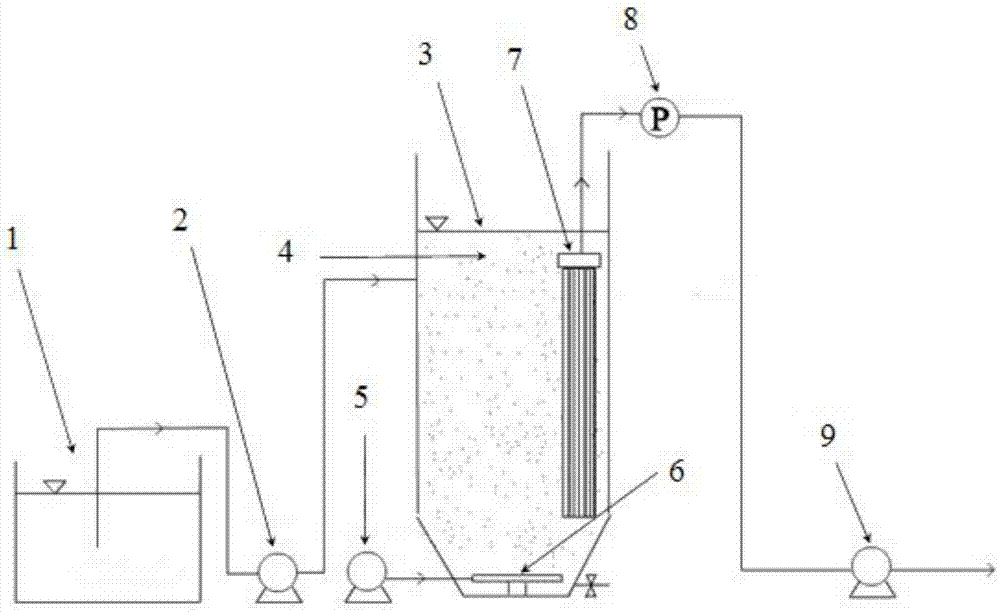

Method used

Image

Examples

Embodiment 1

[0042] Prepare 500L of arsenic-containing wastewater (the pH is 6.1, the total arsenic content is 1mg / L, the content of As(III) is 0.5mg / L, and the content of As(V) is 0.5mg / L), and it is discharged under the action of the water inlet pump. Enter the adsorption reaction tank, add goethite 1g / L to the adsorption reaction tank, turn on the aeration pump, adjust the aeration intensity to 0.2L / min, and aerate and stir for 30min. Turn on the outlet pump, its operating pressure is 0.1MPa, and the purified water passes through the membrane module and is discharged from the adsorption reactor. Collect the effluent, and use the hydride generation-atomic fluorescence (HG-AFS) method to detect the arsenic content in the effluent, which is less than 0.001mg / L. It is lower than the arsenic concentration limit (0.01mg / L) stipulated in the national "GB5749-2006 Sanitary Standard for Drinking Water". During continuous operation, the reading on the pressure gauge does not change.

Embodiment 2

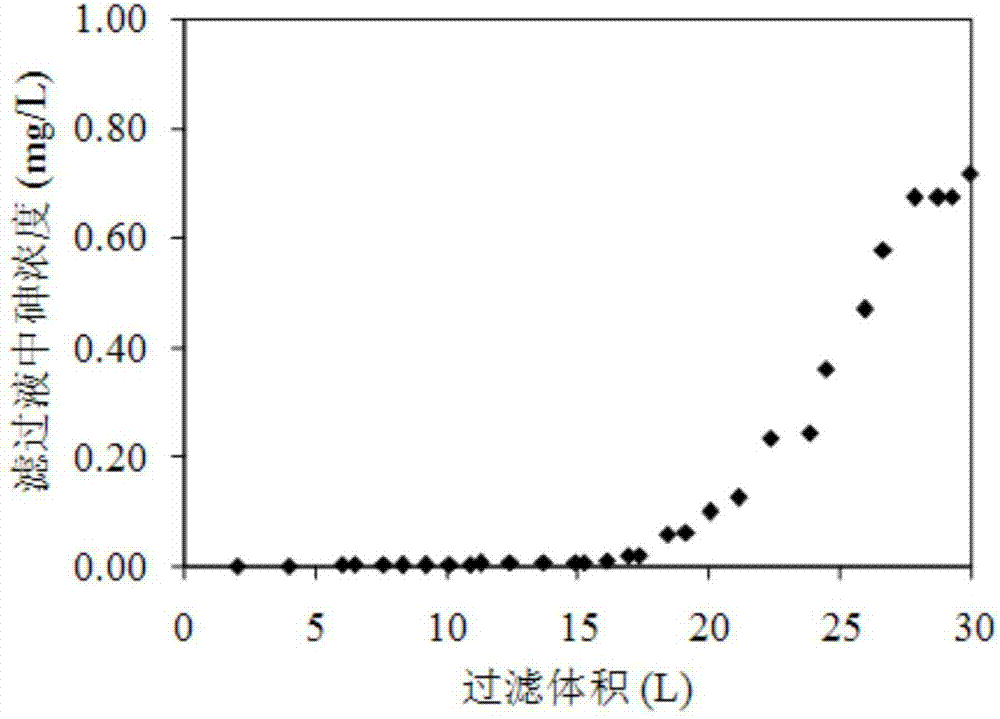

[0044] Prepare 500L of arsenic-containing wastewater (the pH is 6.1, the total arsenic content is 1mg / L, the As(III) content is 0.5mg / L, and the As(V) content is 0.5mg / L), the arsenic content in Songhua River water is The background value is lower than 0.01mg / L, COD Cr It was 346mg / L, and the concentration of suspended particulate matter was 10.5mg / L. Under the action of the water inlet pump, it is discharged into the adsorption reaction tank, 1g / L of goethite is added to the adsorption reaction tank, the aeration pump is turned on, the aeration intensity is adjusted to 0.3L / min, and the aeration is stirred for 30min. Turn on the outlet pump, its operating pressure is 0.1MPa, and the purified water passes through the membrane module and is discharged from the adsorption reactor. Collect the effluent, and use the method of hydride generation-atomic fluorescence (HG-AFS) to detect the arsenic content in the effluent, which is lower than 0.001mg / L, which is lower than the nation...

Embodiment 3

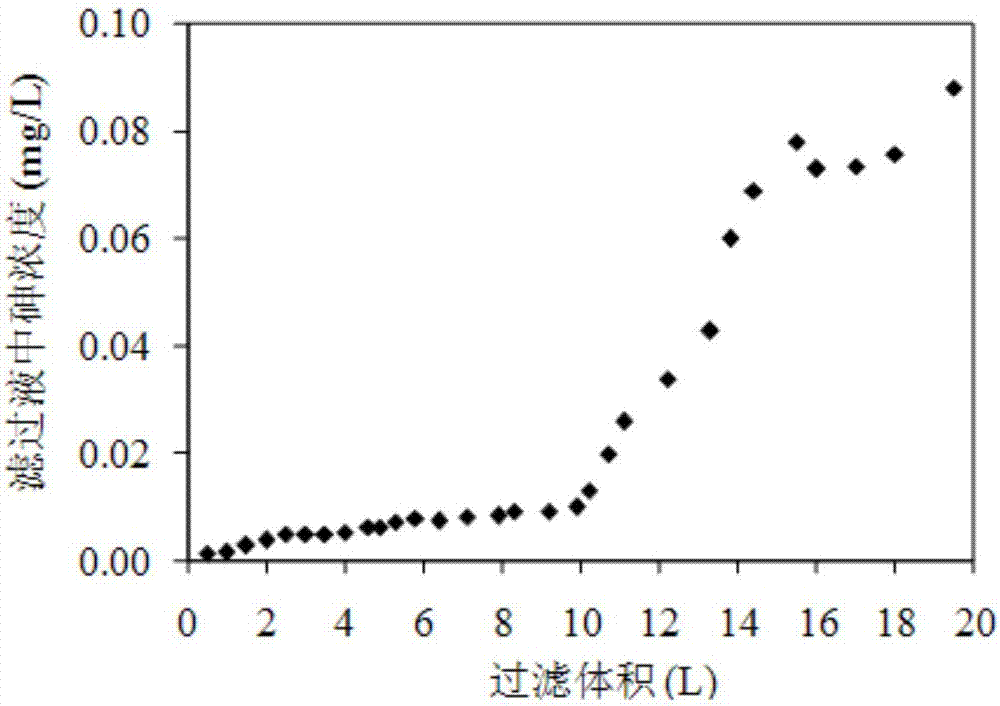

[0046] Prepare 20L of arsenic-containing wastewater (the pH is 6.9, the total arsenic content is 0.1mg / L, the As(III) content is 0.05mg / L, and the As(V) content is 0.05mg / L), under the action of the water inlet pump Discharge into the adsorption reaction tank, add 0.5g / L hematite into the adsorption reaction tank, turn on the aeration pump, adjust the aeration intensity to 0.8L / min, and aerate and stir for 50min. Turn on the outlet pump, its operating pressure is 0.3MPa, and the purified water passes through the membrane module and is discharged from the adsorption reactor. The effluent was collected, and the arsenic content in the effluent was detected by the method of hydride generation-atomic fluorescence (HG-AFS). figure 2 As shown, when the filtration volume does not exceed 10L, the arsenic concentration in the effluent is lower than 0.001mg / L, which is lower than the arsenic concentration limit (0.01mg / L) stipulated in the national "GB5749-2006 Hygienic Standard for Dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com