Casting floating and rotating mechanism

A technology of rotating mechanism and floating mechanism, which is applied in the direction of grinding workpiece support, grinding drive device, grinding machine tool parts, etc. It can solve the problem of inconvenient grinding of brake discs, and achieve manual or automatic grinding and prevent movement. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

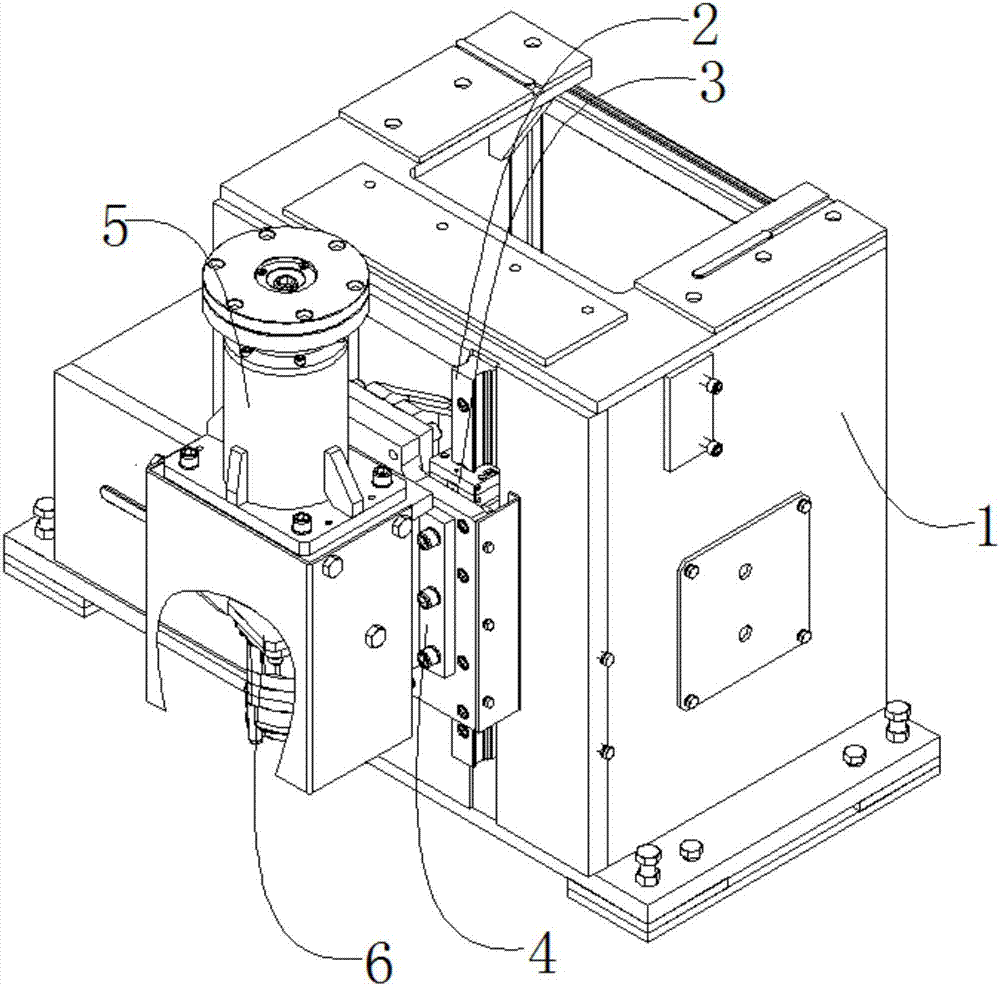

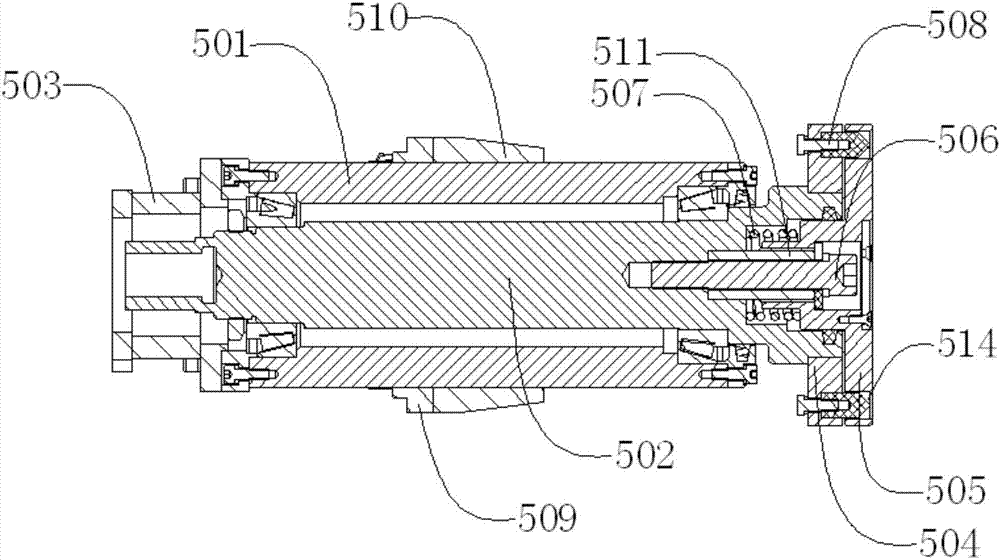

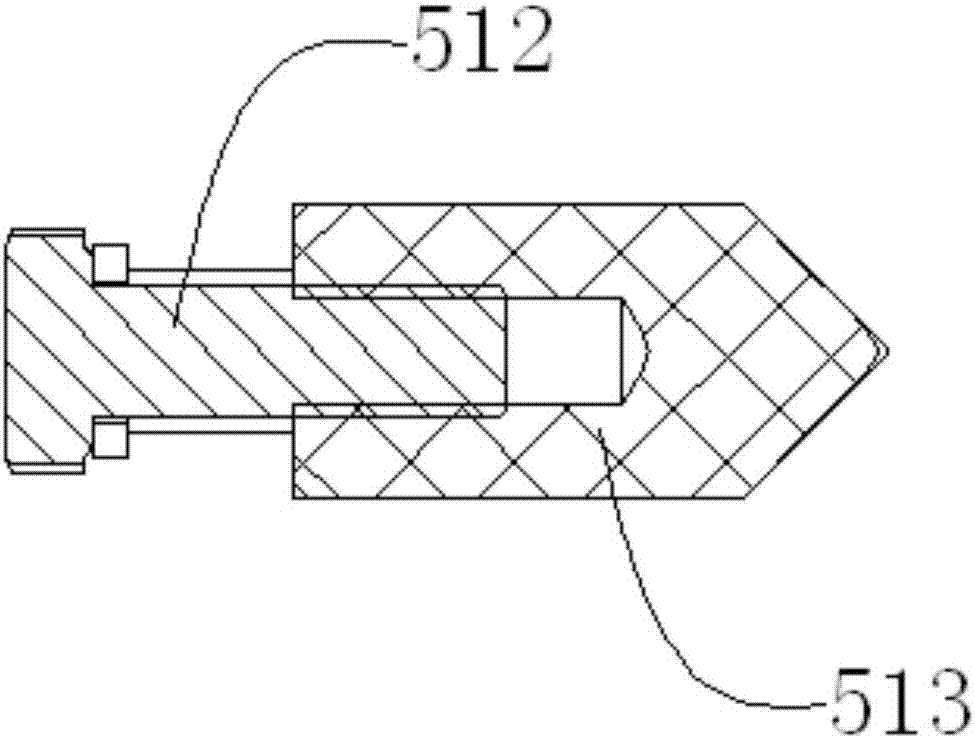

[0019] Such as figure 1 , figure 2 , image 3 As shown, a casting floating rotating mechanism includes a frame 1, a guide rail 2, a slider 3, a sliding plate 4, a floating mechanism 5, and a speed regulating motor 6. The guide rail 2 is located outside the frame 1, and the guide rail 2 is connected with the frame 1 by bolts, the guide rail 2 runs through the slider 3, the slider 3 can move up and down along the guide rail 2, the sliding plate 4 is located outside the slider 3, and the sliding plate 4 It is connected with the slider 3 through bolts, the floating mechanism 5 is located outside the sliding plate 4, the floating mechanism 5 is connected with the sliding plate 4 through bolts, the speed regulating motor 6 is located at the lower end of the floating mechanism 5, and the The speed-regulating motor 6 is connected with the floating mechanism 5 through bolts, and the floating mechanism 5 also includes a shaft sleeve 501, a rotating shaft 502, a motor seat 503, a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com