Processing method of PVC pipe joint

A PVC pipe and processing method technology, which is applied to metal processing equipment, manufacturing tools, tangent devices, etc., can solve the problems of complicated control methods of the internal thread processing machine for PVC pipe joints, save labor resources, avoid the influence of processing accuracy, Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0045] A processing method for a PVC pipe joint, characterized in that it comprises the following processing steps:

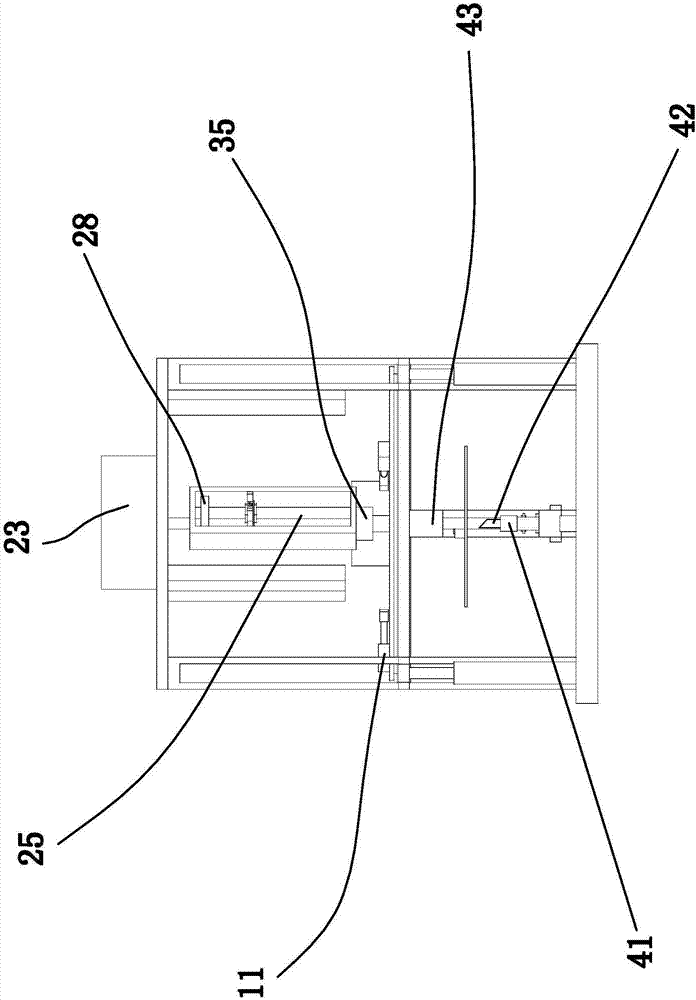

[0046] 1) Positioning and clamping: position and clamp the annular PVC pipe to be processed on the thread cutting device. The thread cutting device includes a frame body, a workbench, a drive motor 1 23, a drive motor 2 35, a drive motor 3 48, and a push cylinder 1 40, push cylinder two 43, push cylinder three 46, push cylinder four 54, push cylinder five 55, turning tool one 32, turning tool two 42, turning tool three 45 and turning tool four 53, workbench includes lifting plate 7 and work Plate 9, the annular PVC pipe to be processed is positioned and clamped through the clamping mechanism on the workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com