Desulphurization dust removal process of smoke clean emission

A technology for desulfurization, dust removal and flue gas, applied in gas treatment, use of liquid separation agent, membrane technology, etc., can solve the problems of increasing flue gas resistance, high energy consumption, and high operating costs, achieving high dust removal rate and reducing secondary pollution. the effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

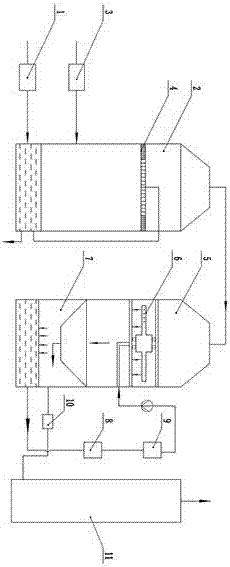

[0028] see figure 1 , the desulfurization and dust removal system for clean flue gas discharge in the illustration is a preferred embodiment of the present invention, including a desulfurization system, a flue gas washing system and a flue gas discharge system. The desulfurization system is composed of an absorption tower, a desulfurizer preparation and a circulation system; The flue gas washing system consists of a cooling scrubber and a washing water supply system. The cooling scrubber is a water spray tower; the flue gas discharge system includes a chimney, and the cleaned flue gas is finally discharged through the chimney.

[0029] In this example, magnesium flue gas desulfurization is adopted, and the specific process is as follows:

[0030] After the purchased MgO powder is matured and digested, it is sent to the desulfurizer slurry tank 1, and the produced Mg(OH) 2 The emulsion (absorbing liquid) is sent to the absorbing liquid pool at the lower part of the absorption ...

example 1

[0043] Flue gas condition: 8000Nm3 / h; SO 2 The concentration is 800mg / L; the dust concentration is 50 mg / L; the boiler flue gas temperature: 120°C.

[0044] Measured after the steps of the foregoing examples:

[0045] Temperature after absorption tower: 55°C; Temperature after low-temperature washing tower: 30°C;

[0046] After the flue gas is cleaned, the SO 2 The concentration is 1.5mg / L; the dust concentration is 0.5 mg / L.

[0047] Desulfurization efficiency: 99.8% Dust removal efficiency: 99%

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com