Binder for solvent-based printing ink, and solvent-based printing ink including same

A printing ink and adhesive technology, which is applied in the field of solvent-based printing ink adhesives and solvent-based printing inks, can solve the problem of insufficient ink resolubility, poor ink stability, and poor boiling resistance. problems, to achieve the effects of excellent ink stability, excellent boiling resistance, and less blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

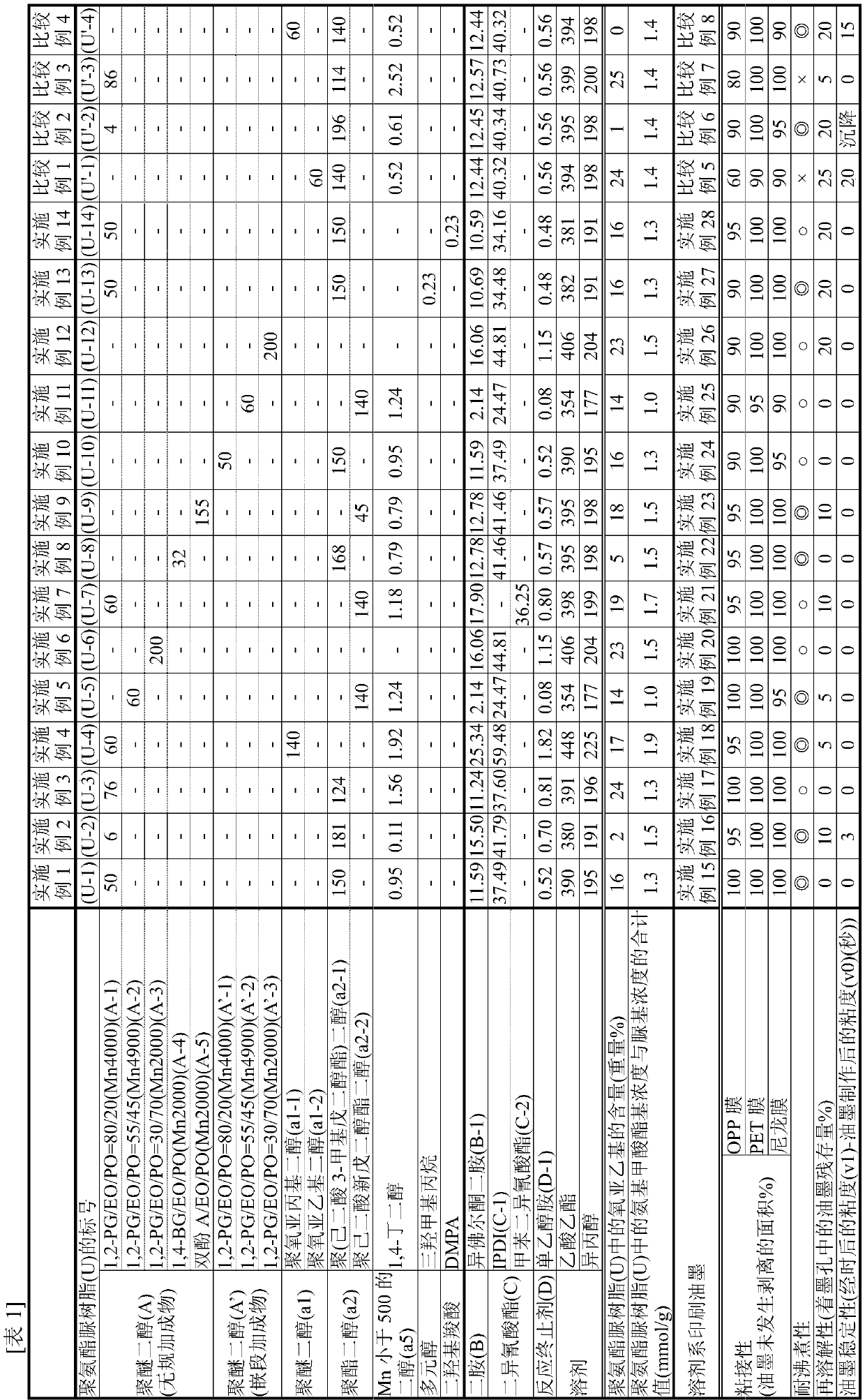

Examples

manufacture example 1

[0115] After adding 57.9 parts of 1,2-propanediol and 1.0 parts of potassium hydroxide into a reaction vessel with a stirring device and a temperature control device, continuously add 2380.3 parts of EO while controlling the reaction temperature at 100°C to 110°C under stirring and PO 540.8 parts. 60.0 parts of water and 60.0 parts of alkali adsorbent "Kyoward 600" (manufactured by Kyowa Chemical Industry Co., Ltd.) were added to the obtained crude polyether polyol containing a catalyst, purified by adsorption treatment, filtration, and drying, and further added 3- (3,5-di-tert-butyl-4-hydroxyphenyl) 6-methylheptyl propionate ("IRGANOX1135" manufactured by BASF Japan Co., Ltd.) 0.9 parts, stirred and dissolved to obtain polyether diol (A-1) 3000 copies. Polyether diol (A-1) is an EO / PO random addition product of 1,2-propanediol, and the weight ratio of EO / PO is 80 / 20 and Mn=4000.

manufacture example 2

[0117] After adding 50.6 parts of 1,2-propanediol and 1.0 parts of potassium hydroxide into a reaction vessel with a stirring device and a temperature control device, continuously add 1651.2 parts of EO while controlling the reaction temperature at 100°C to 110°C under stirring and PO 1297.2 parts. 60.0 parts of water and 60.0 parts of alkali adsorbent "Kyoward 600" (manufactured by Kyowa Chemical Industry Co., Ltd.) were added to the obtained crude polyether polyol containing a catalyst, purified by adsorption treatment, filtration, and drying, and further added 3- (3,5-di-tert-butyl-4-hydroxyphenyl) 6-methylheptyl propionate ("IRGANOX1135" manufactured by BASF Japan Co., Ltd.) 0.9 part, stirred and dissolved to obtain polyether diol (A-2) 3000 copies. Polyether diol (A-2) is an EO / PO random addition product of 1,2-propanediol, and the weight ratio of EO / PO is 55 / 45 and Mn=4900.

manufacture example 3

[0119] After adding 87.8 parts of 1,2-propanediol and 1.0 parts of potassium hydroxide into a reaction vessel equipped with a stirring device and a temperature control device, continuously add 898.7 parts of EO while controlling the reaction temperature at 100°C to 110°C under stirring and PO 2012.5 copies. 60.0 parts of water and 60.0 parts of alkali adsorbent "Kyoward 600" (manufactured by Kyowa Chemical Industry Co., Ltd.) were added to the obtained crude polyether polyol containing a catalyst, purified by adsorption treatment, filtration, and drying, and further added 3- (3,5-di-tert-butyl-4-hydroxyphenyl) 6-methylheptyl propionate ("IRGANOX1135" manufactured by BASF Japan Co., Ltd.) 0.9 part, stirred and dissolved to obtain polyether diol (A-3) 3000 copies. Polyether diol (A-3) is an EO / PO random addition product of 1,2-propanediol, and the weight ratio of EO / PO is 30 / 70 and Mn=2000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com