Triangular cable with optical fiber

An optical cable and triangular technology, applied in the field of triangular cables, can solve the problems of troublesome use and maintenance, short circuit of cables, shortened service life of cables, etc., and achieve the effect of saving filling materials and wrapping tapes, reducing material waste, and convenient use and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

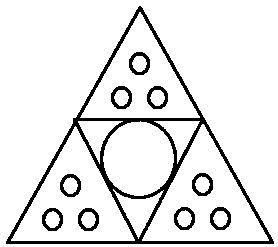

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] The structure of the present invention is as figure 1 As shown, the cable includes a triangular optical cable and a triangular structure formed by combining three triangular cores twisted around the optical cable. The triangular optical cable includes an optical cable core and a triangular protective layer covering the optical cable; the triangular wire The core includes several wire cores and an insulating layer covering the wire cores in a triangular shape.

[0014] As a further improvement, the number of said wire cores is one to three.

[0015] Both the wire core and the optical cable core of the present invention are dragged directly, which saves filling materials and wrapping tapes, reduces the material waste of twisting to increase the length, and reduces weight; and there is no entanglement between the wire core and the optical cable core, and the identifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com