Method for modeling HI concentrating rectifying tower in iodine-sulfur circulating hydrogen production

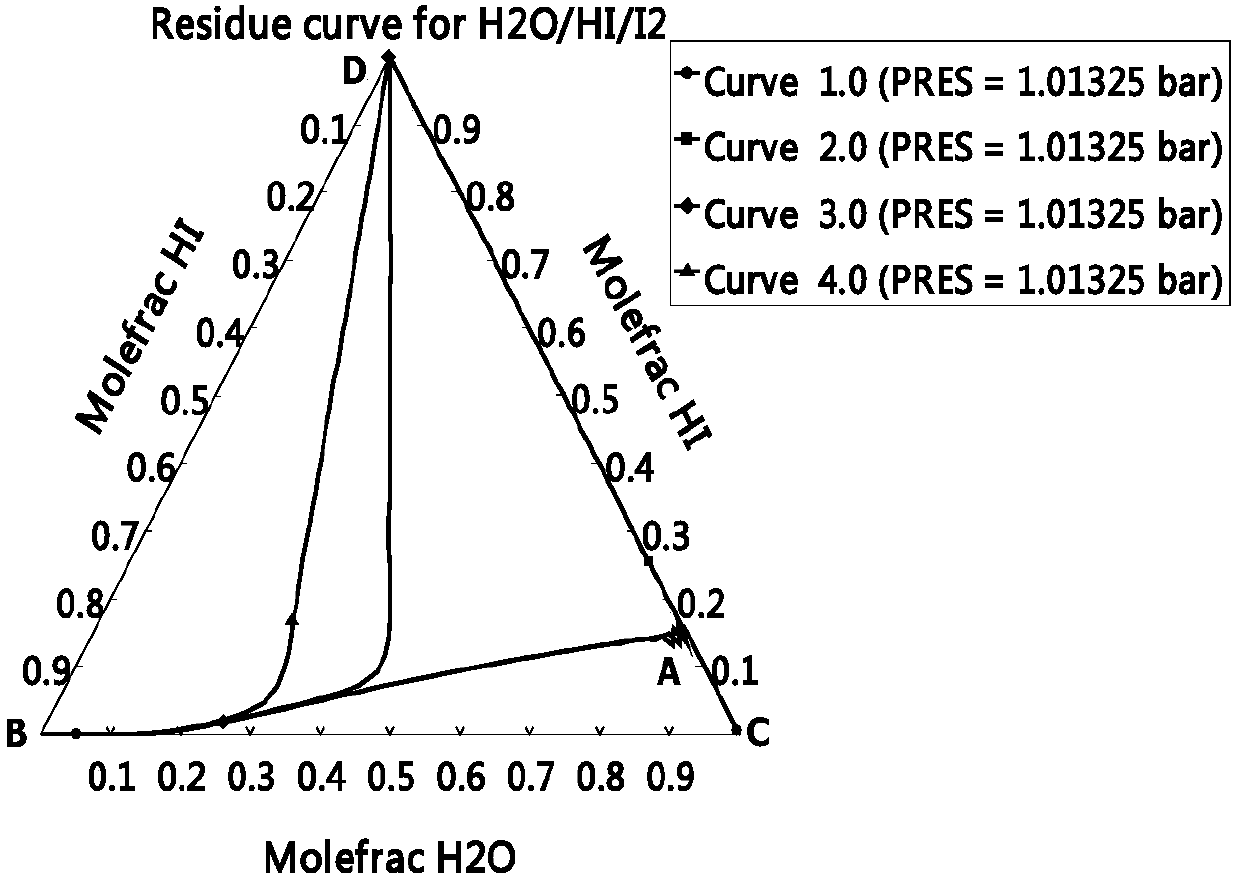

A modeling method and technology of rectification tower, which is applied in the field of modeling of HI-I2-H2O system and homogeneous azeotropic distillation tower, can solve problems such as poor efficiency of HI concentration, separation and rectification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

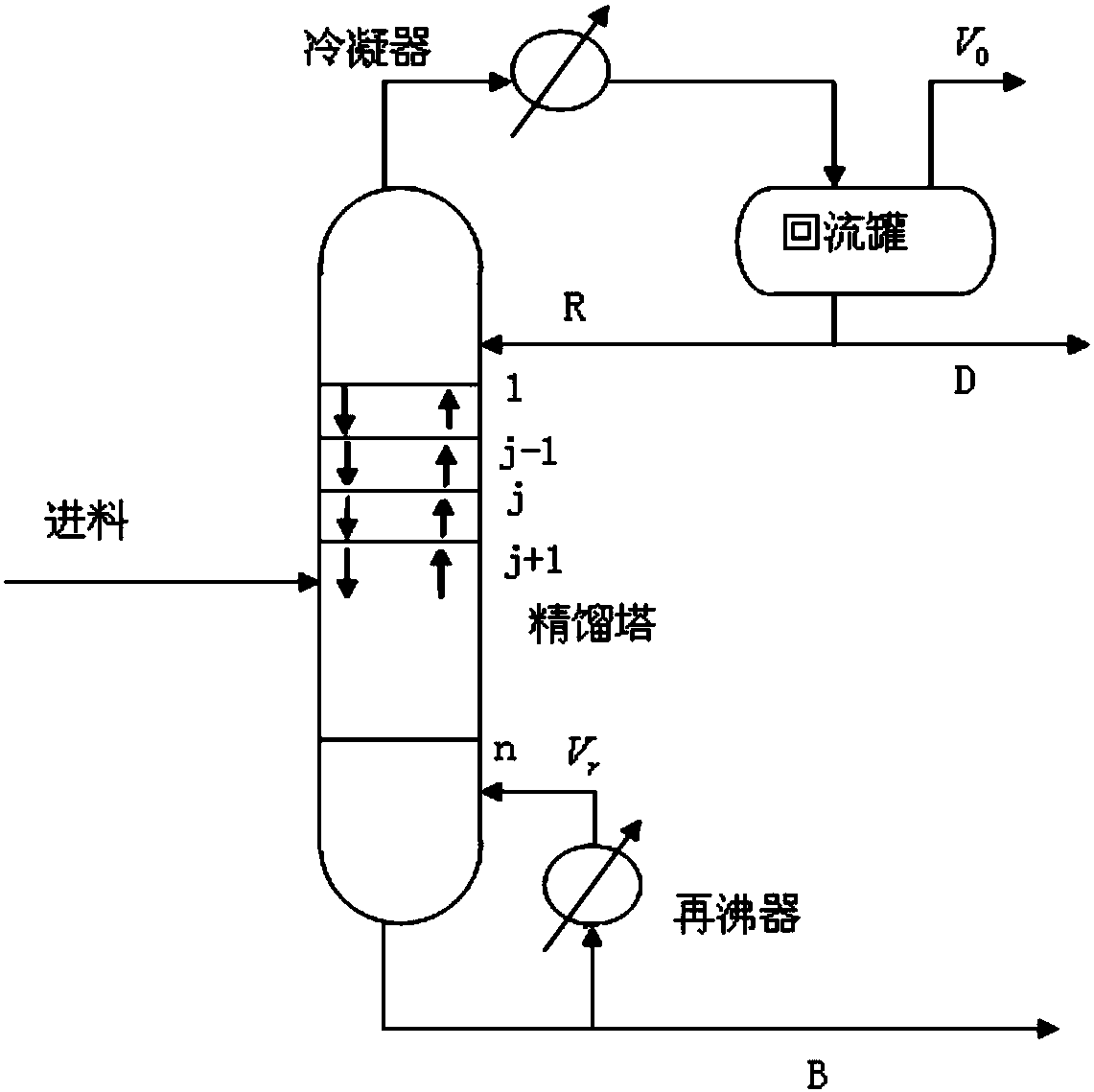

[0030] attached figure 1 It is a flow chart of the HI concentrated rectification of a certain EED process, the raw material liquid (HI and H obtained from the Bunsen reaction 2 SO 4The mixed solution) F1 is divided into two streams F2, F3 into the anode and cathode of the EED respectively, and the stream treated by the EED process, because HI is enriched on the cathode side and the cathode side of the outlet fluid, the stream F9 is It is returned to the Bunsen reaction to make the raw material liquid, the stream F8 on this side enters the heat exchanger, and then the stream is heated by the heat exchanger to reach the bubble point temperature, and the stream 11 enters the rectification column, and the overhead distillation Produce high-purity HI, the F13 stream of high-purity HI provides raw materials for the decomposition reaction, and produces a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com