Compact technological arrangement method of heat recovery coke oven high-temperature smoke system

A high-temperature flue gas and heat recovery technology, which is applied in the field of high-temperature flue gas system layout, can solve the problems of high-temperature flue gas pollution without treatment, achieve high heat energy utilization, reduce heat dissipation, and reduce system leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

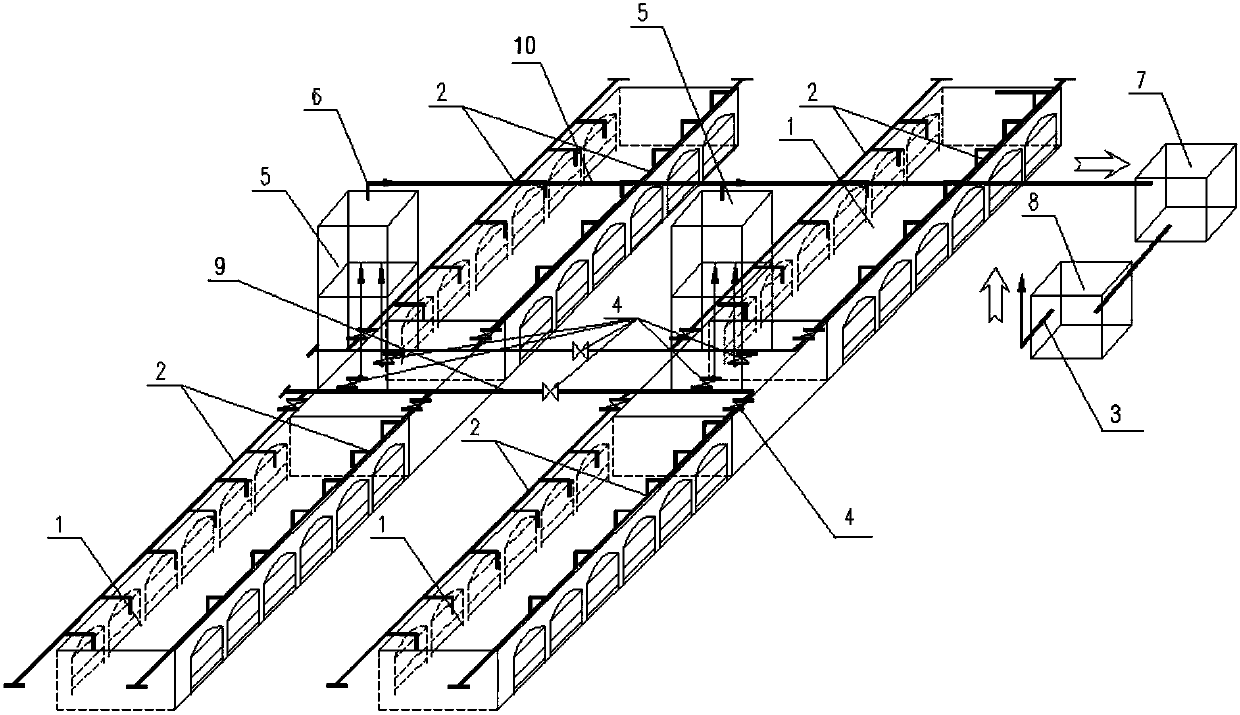

[0023] A compact process layout method for heat recovery coke oven high-temperature flue gas system, including four heat recovery coke ovens 1, two waste heat boilers 5, one fan 7, one desulfurization and dust removal unit 8, two heat recovery coke ovens 1 For one column, two columns are arranged in parallel.

[0024] A waste heat boiler 5 is arranged in the middle of two adjacent heat recovery coke ovens 1 . The high temperature flue gas collecting pipe 2 of each heat recovery coke oven collects high temperature flue gas and then enters the waste heat boiler 5 from the lower inlet of the waste heat boiler. A cut-off valve 4 is provided at the inlet of the waste heat boiler 5 .

[0025] A low-temperature flue gas pipeline 6 is arranged on the top of the waste heat boiler 5, and the low-temperature flue gas pipeline 6 is sequentially connected to a fan 7, a desulfurization and dust removal unit 8, and the desulfurization and dust removal unit 8 is provided with a flue gas outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com