Inflatable geobag and construction method thereof

A construction method and technology of geotechnical bags, which are applied in the direction of bagging, excavation, sacks, etc., can solve the problems of restricting the promotion of geotechnical bags, low construction efficiency, single structure, etc., and achieve high construction efficiency, space saving and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

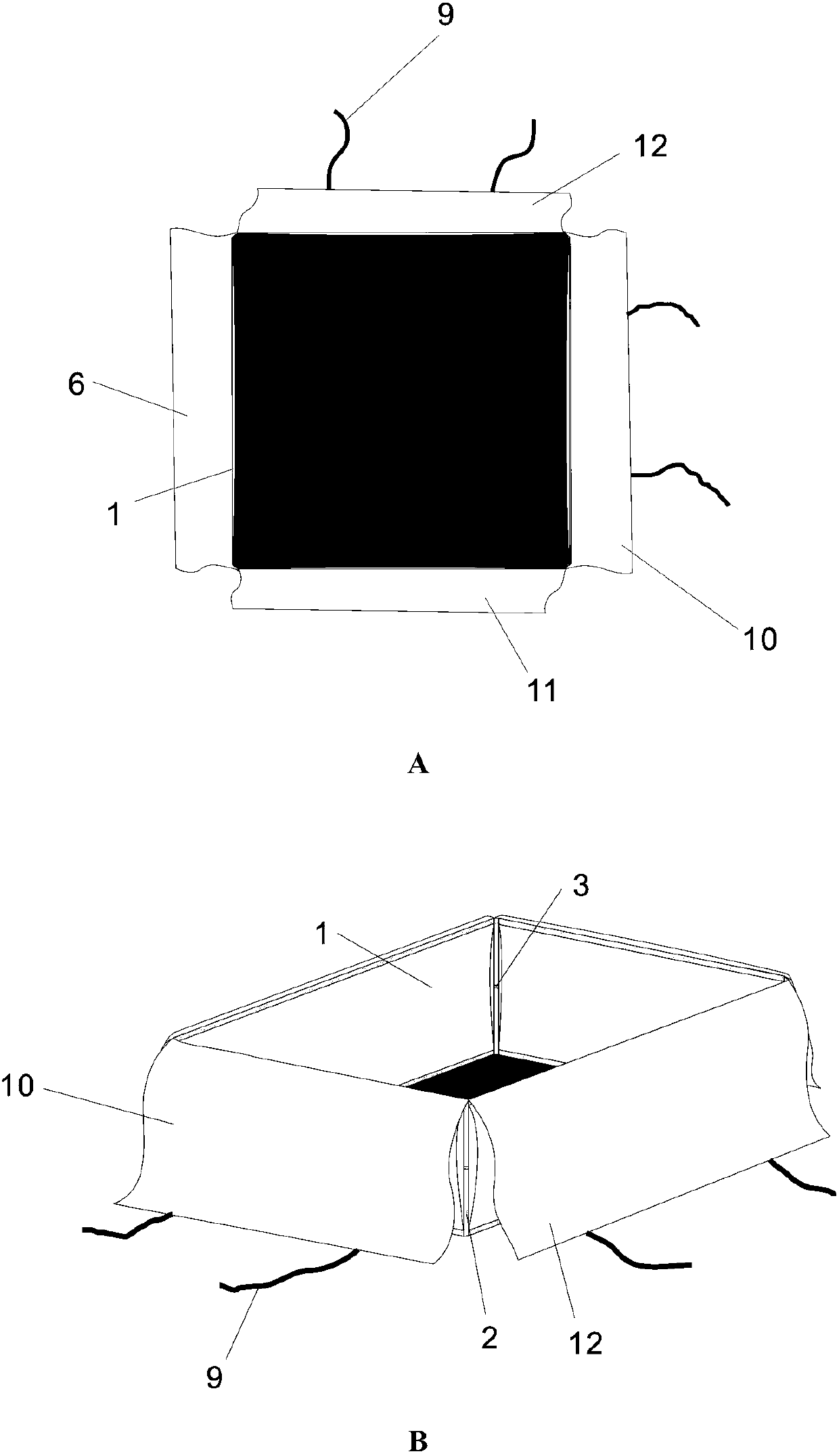

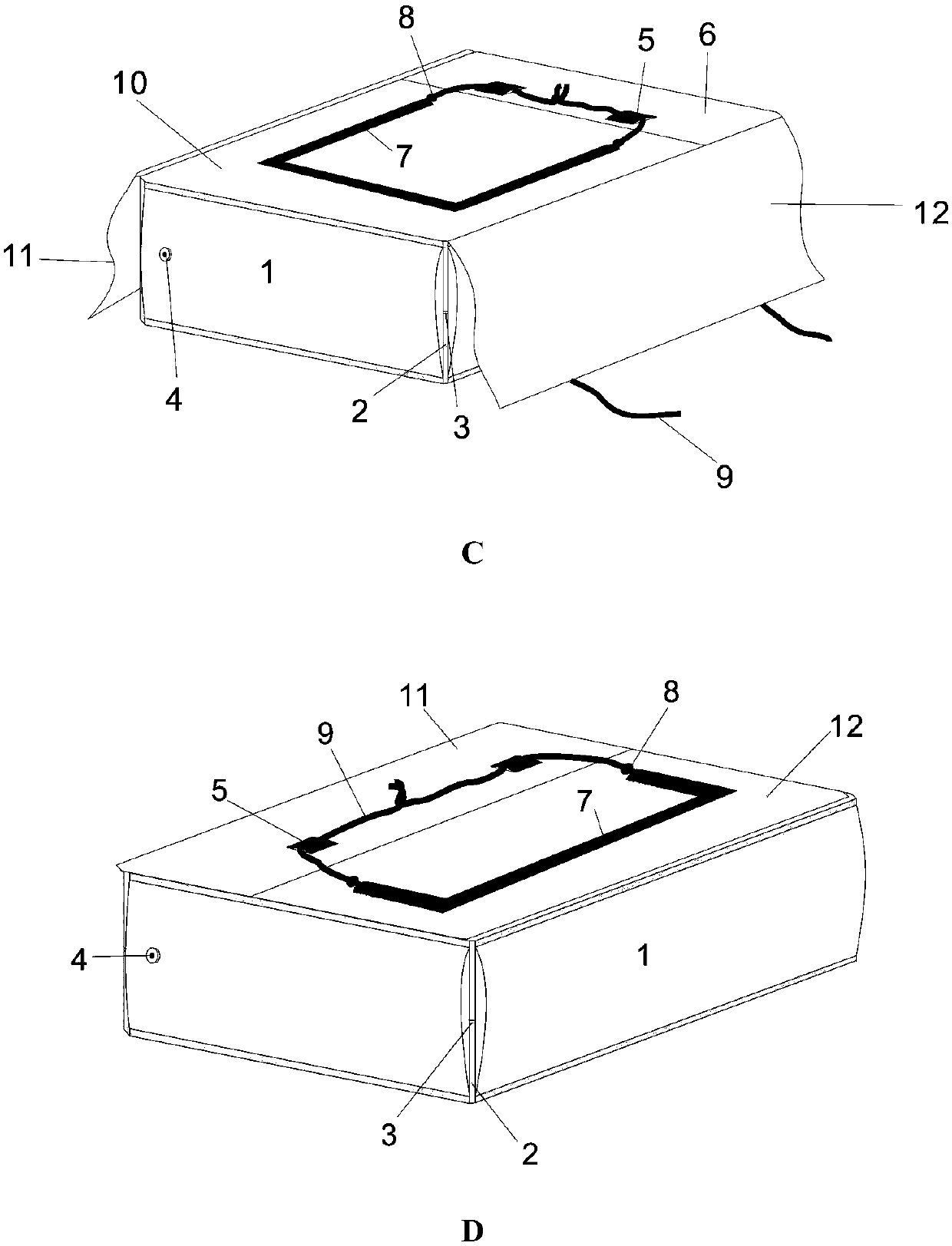

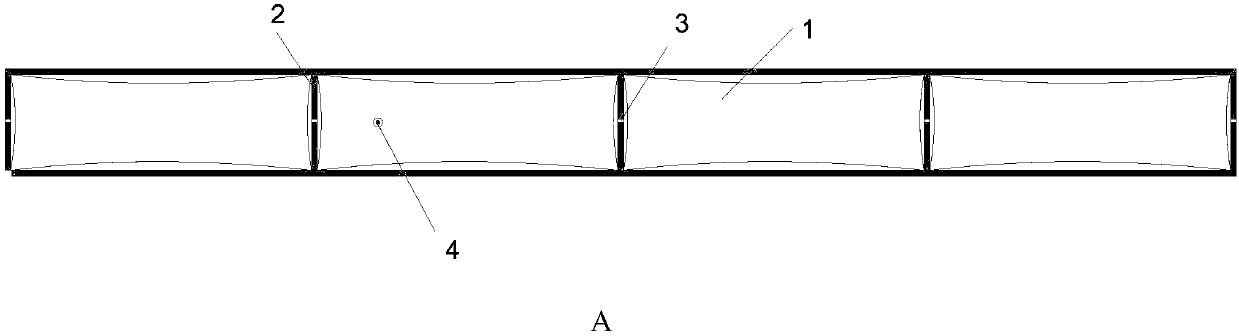

[0032] An inflatable geotechnical bag, the geotechnical bag is composed of at least one geotechnical bag unit, and the geotechnical bag unit is a semi-closed structure composed of a top sealing material, a bottom sealing material 13 and a circumferential double-layer geomembrane 1; wherein, the bottom sealing The edge between the material 13 and the double-layer geomembrane 1 is closed, and the adjacent edge of the double-layer geomembrane 1 is treated with the edge 2, and the air hole 3 is provided on the edge 2; the double-layer geomembrane 1 and the The crimping is closed between the top sealing materials; the annular double-layer geomembrane 1 is provided with an inflation port 4 .

[0033] The geotechnical bag unit is a square structure.

[0034] The top sealing material is divided into 4 pieces, namely the top sealing material sheet 16, the top sealing material sheet 210, the top sealing material sheet 311 and the top sealing material sheet 412, wherein two adjacent mate...

Embodiment 2

[0040] The geotechnical bag described in embodiment 1 is applied to the slope protection structure, and the construction method is as follows:

[0041] Step 1. Level the base bearing surface, and spread the geotextiles on the base bearing surface in turn;

[0042] Step 2, open the inflation valve port 15, use the inflation device to inflate the ring to the double-layer geomembrane 1, close the plug air sleeve 16 to close the inflation valve port 15, until each geobag unit is a three-dimensional box shape;

[0043] The 3rd step, the top sealing material sheet 1 6, the top sealing material sheet 2 10, the top sealing material sheet 3 11 and the top sealing material sheet 4 12 are unfolded from the inside, and it is placed on the outside of the geotechnical bag, and then to the inside of the geotechnical bag Fill with earth and stone or water, stop when filling close to the height of the geotechnical bag, fold the top sealing material sheet 1 6 and the top sealing material sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com