Emulsified aged crude oil treatment system and treatment method

A technology of aging crude oil and treatment system, which is applied in the field of emulsified aging crude oil treatment system, can solve the problems of complex processing process, high cost, incomplete processing, etc., and achieve the effect of low cost, simple process flow and reduced processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

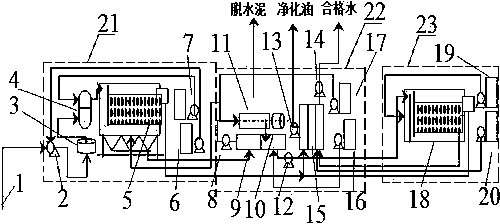

[0033] This embodiment provides a treatment system for emulsified aged crude oil, comprising a reaction separation skid 21, a solid-liquid separation skid 22, and a purification separation skid 23. The upper outlet of the reaction separation skid 21 is connected to the solid-liquid separation skid 22, purification The separation skid 23 is connected, the bottom outlet of the reaction separation skid 21 is connected with the solid-liquid separation skid 22 through a pipeline, and the water outlet of the purification separation skid 23 is connected with the solid-liquid separation skid 22 through a pipeline.

[0034] The reaction separation skid 21 is used for the separation of oil, suspended sludge and water, the solid-liquid separation skid 22 can realize solid-liquid separation, and the purification separation skid 23 can realize the quality of oil and water reaching the standard.

Embodiment 2

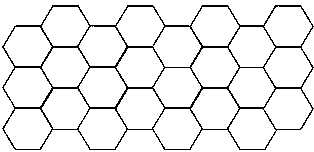

[0036] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the emulsified aged crude oil treatment system shown, the reaction separation skid 21 includes a skid base I and a heat exchanger 3 located on the skid base I, a stirring tank 4, a reaction tank 5, a dosing device A6 and a dosing device B 7 , the dosing device A6 is communicated with the emulsified aged crude oil inlet, the emulsified aged crude oil inlet, the heat exchanger 3, the stirring tank 4, and the reaction tank 5 are sequentially communicated, and the dosing device B7 is communicated with the stirred tank 4, and the The reaction tank 5 is provided with a honeycomb filler (ZY-03 material), which is composed of a hydrophilic and oleophobic base layer and an oleophilic and hydrophobic surface coating, and the oleophilic and hydrophobic surface coating is coated on the hydrophilic and oleophobic base. The diameter of the honeycomb filler is 50mm. This material can slow down the moving spee...

Embodiment 3

[0046] On the basis of embodiment 1 or embodiment 2, this embodiment provides a kind of emulsified aging crude oil processing system, also comprises sludge bagging vehicle and treatment field anti-seepage ground layer, and described sludge bagging vehicle is used for coordinating The solid-liquid separation skid 22, the reaction separation skid 21, the solid-liquid separation skid 22 and the purification separation skid 23 are all arranged on the anti-seepage ground layer of the treatment field, and the anti-seepage ground layer of the treatment field is polyurethane with a relative molecular mass greater than 10,000 . Polyurethane is an anti-seepage material with good wear resistance, flexural resistance and corrosion resistance, which can effectively prevent harmful pollutants from penetrating into the formation and solve the pollution problem.

[0047] It also includes an electric control system, and the electrical components on the reaction separation skid 21, the solid-li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com