Landfill leachate collecting and treating device

A landfill leachate and treatment device technology, which is applied in the direction of polluted groundwater/leachate treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of bad smell, unfavorable waste incineration treatment, etc. problems, to achieve the effect of improving functionality and practicability, saving waste disposal procedures, and improving treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

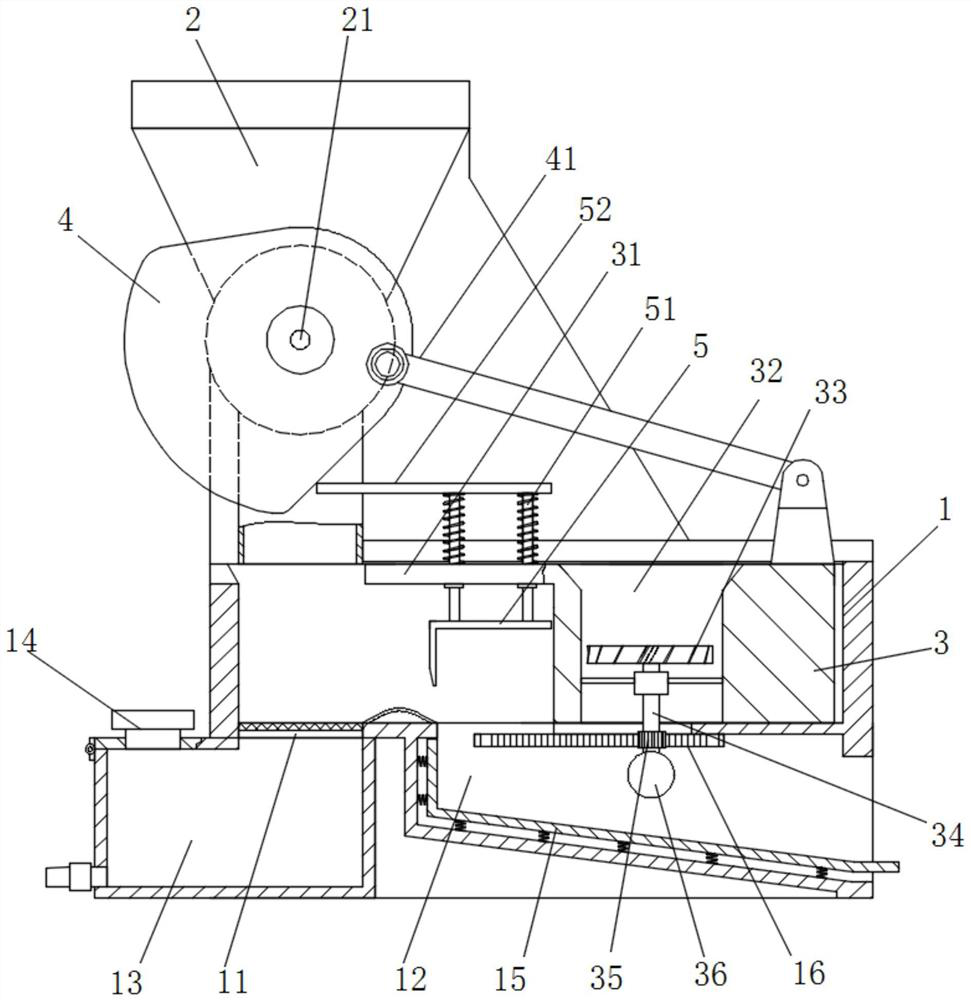

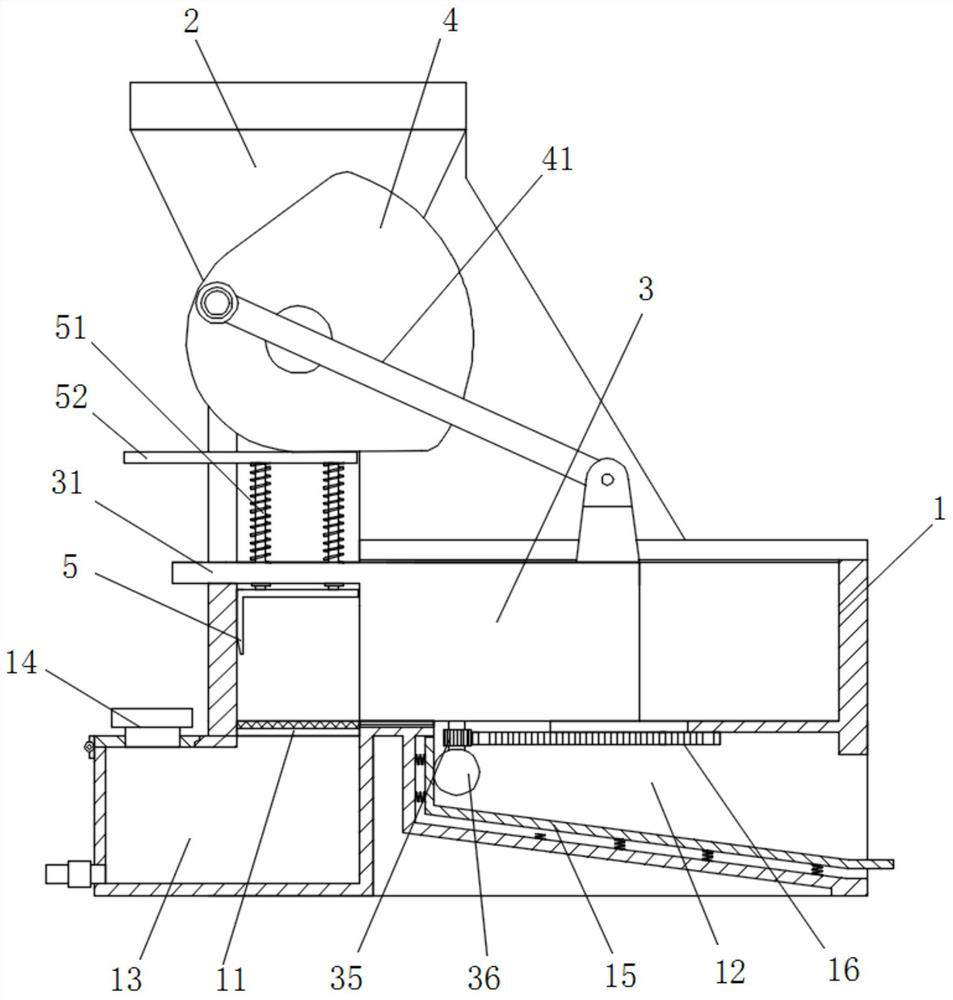

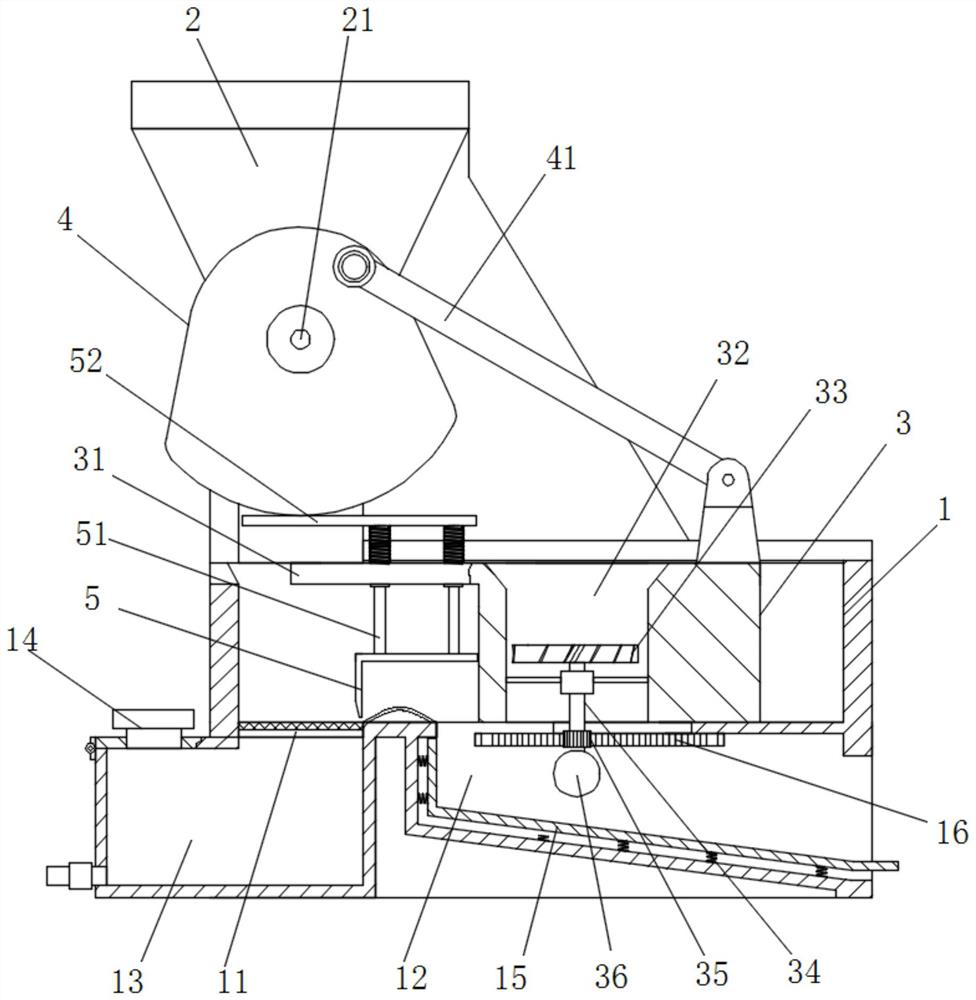

[0028] The present invention provides such figure 1 - Figure 5 The landfill leachate collection and treatment device shown includes a machine base 1, a feeding hopper 2 is installed on the top of one end of the machine base 1, and the feeding hopper 2 is relatively fixed to the machine base 1, and the inside of the machine base 1 is opened There is a compression groove, and a horizontal pressure seat 3 is slidably installed in the compression groove. The end of the compression groove of the machine base 1 close to the bottom port of the feeding hopper 2 is provided with a filtrate port 11, and the middle part of the machine base 1 is provided with a solid outlet. 12. The inside of the filtrate port 11 is fixed with a water filter plate, the bottom of the filtrate port 11 is installed with a liquid collection tank 13 for receiving the sewage filtered by the filtrate port 11, and the inside of the feeding hopper 2 is rotated. Shaft 21, the outer end of the drive shaft 21 is fi...

Embodiment 2

[0035] Based on Example 1, the difference is that, as figure 1 and image 3 As shown in a landfill leachate collection and treatment device, the inside of the horizontal pressure seat 3 is provided with an air exhaust port 32 , the air exhaust port 32 penetrates up and down, and the bottom of the air exhaust port 32 communicates with the solid outlet 12 , the inner rotation of the air exhaust port 32 is equipped with a fan 33, and the rotation of the fan 33 drives the air flow in the solid outlet 12, and air-dries the solid waste flowing out through the solid outlet 12;

[0036] Further, in the above technical solution, the inside of the fan 33 is fixedly connected with a fan shaft 34, the fan shaft 34 is rotatably supported by a support frame installed inside the air outlet 32, and the bottom end of the fan shaft 34 is fixed A gear 35 is connected, and the inside of the solid outlet 12 is fixedly equipped with a rack 16 meshing with the gear 35. When the horizontal pressure ...

Embodiment 3

[0039] Based on Example 2, the difference is, such as figure 1 - image 3 As shown in a landfill leachate collection and treatment device, the inside of the solid outlet 12 is equipped with a discharge inclined bucket 15, and the end of the discharge slope 15 close to the outside of the machine base 1 is inclined downward. The inclined bucket 15 guides the solid waste to fall out;

[0040] Further, in the above technical solution, the discharge inclined bucket 15 is connected to the inner cavity of the solid outlet 12 through a plurality of second elastic members, the second elastic members are short springs, and the bottom end of the fan shaft 34 An impact part 36 is fixedly connected to collide with the discharge inclined bucket 15. After the horizontal pressure seat 3 slides toward the filtrate port 11, the impact part 36 is driven close to the end wall of the discharge inclined bucket 15, and the impact on the discharge inclined bucket 15 Impact to make the discharge inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com