Bag type dust collector for stamping coke oven

A bag-type dust collector and tamping coke oven technology, applied in coke ovens, furnace prevention/removal of fouling, chemical instruments and methods, etc. Eliminate escape, avoid environmental pollution, and avoid the effect of flue gas accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

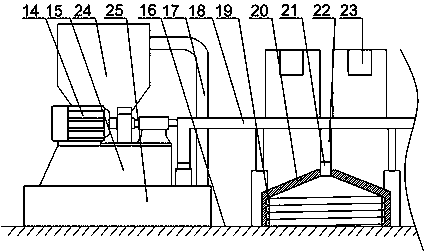

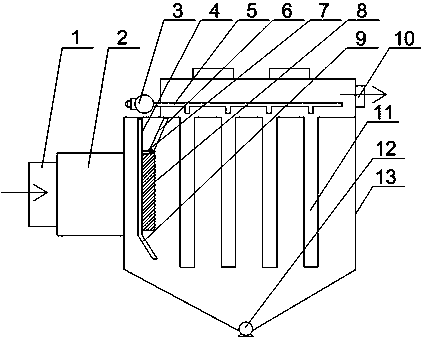

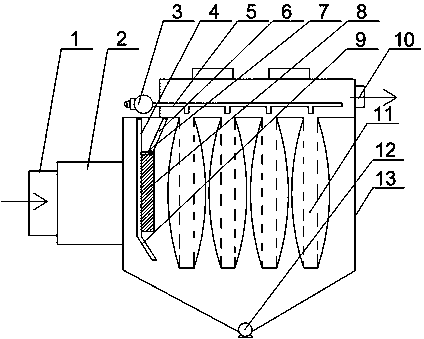

[0026] Such as Figure 1~Figure 3 As shown, the present embodiment is provided with a support seat 15 on the furnace roof baseline 3, and the blower fan 14 and the dust collector 24 are fixed on the support seat 15, and also includes a main air pipe 18, an ascending pipe 17, a temporary storage cavity 25 and multiple A gas collecting hood 20, the gas collecting hood 20 is covered on the outer side of two adjacent coke-side small burners, one end of the main air pipe 18 communicates with the air suction port of the blower fan 14 and the temporary storage cavity 25 respectively, The other end of the trachea 18 communicates with a plurality of the gas collecting hoods 20 through the bronchus 9, one end of the rising pipe 17 communicates with the air inlet of the dust collector 24, and the other end of the rising pipe 17 communicates with the temporary storage cavity 25; the gas collecting hood 20 It is composed of a collection section and a refraction section connected to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com