Packaging glue and preparation method thereof

A technology of packaging glue and glue adjuster, which is applied in the direction of adhesives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve problems such as poor bonding ability and poor coating effect, and achieve high bonding ability, Uniform gluing to solve the effect of high temperature creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

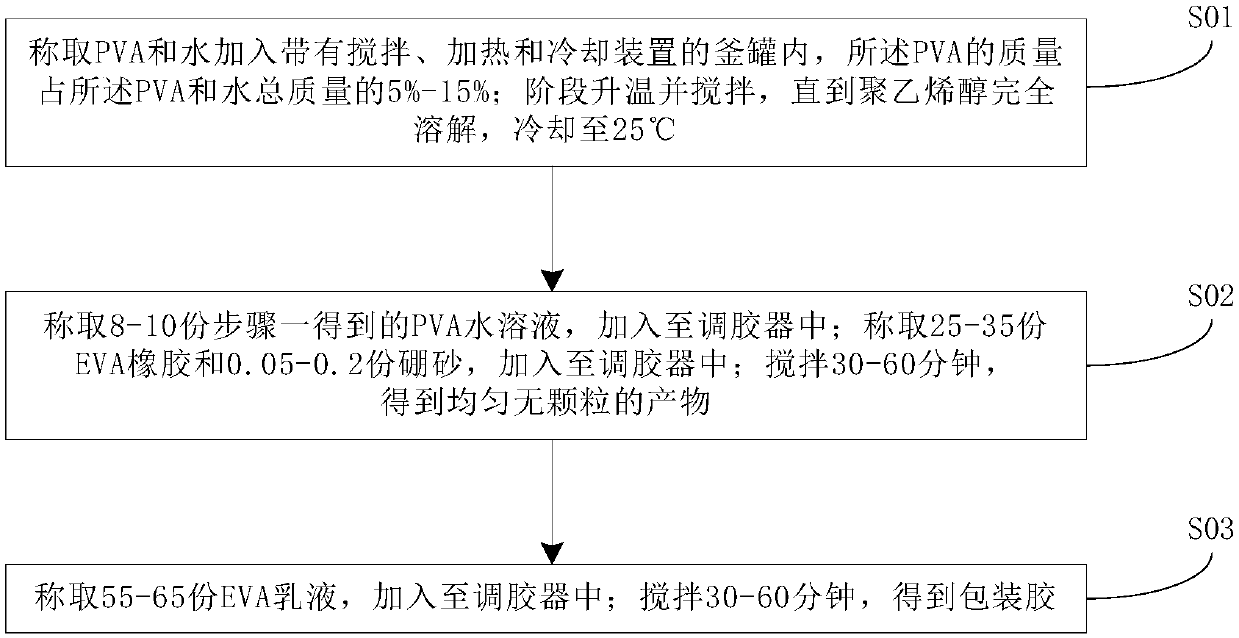

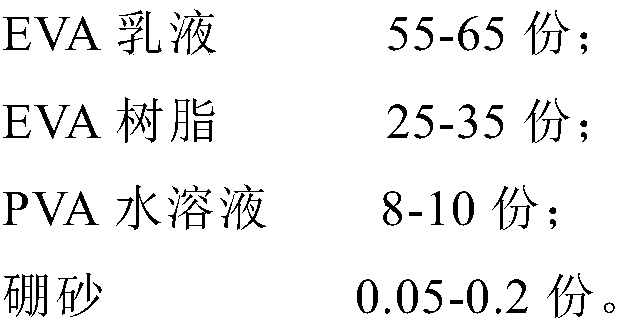

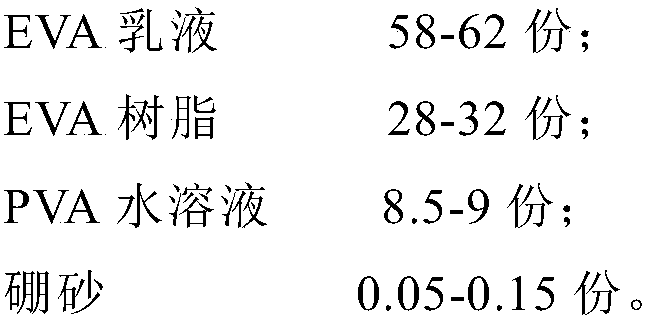

[0037] The embodiment of the present application also provides the preparation method of the above-mentioned packaging glue, refer to figure 1 , the method includes the following steps:

[0038] Step S01, weighing PVA and water and adding it into a kettle with stirring, heating and cooling devices, the quality of the PVA accounts for 5%-15% of the total mass of the PVA and water; stage heating and stirring until polyethylene The alcohol is completely dissolved and cooled to 25°C;

[0039] PVA is polyvinyl alcohol, organic compound, white flaky, flocculent or powdery solid, odorless. Soluble in water, insoluble in gasoline, kerosene, vegetable oil, benzene, toluene, dichloroethane, carbon tetrachloride, acetone, ethyl acetate, methanol, ethylene glycol, etc. Slightly soluble in dimethyl sulfoxide. Polyvinyl alcohol is an important chemical raw material for the manufacture of polyvinyl acetal, gasoline-resistant pipes and vinylon synthetic fibers, fabric treatment agents, emu...

Embodiment 1

[0048] Step S110, weighing PVA and water and adding it into a kettle with stirring, heating and cooling devices, the quality of the PVA accounts for 10% of the total mass of the PVA and water; stage heating and stirring until the polyvinyl alcohol is completely dissolved , cooled to 25°C;

[0049] Step S120, weighing 9 parts of the PVA aqueous solution obtained in step S110, and adding it to the glue adjuster; weighing 30 parts of EVA rubber and 0.1 part of borax, and adding them to the glue adjuster; stirring for 50 minutes to obtain a uniform product without particles;

[0050] Step S130, weighing 60 parts of EVA emulsion, adding to the glue adjuster; stirring for 60 minutes to obtain 1# packaging glue.

Embodiment 2

[0052] Step S210, weighing PVA and water and adding it into a kettle with stirring, heating and cooling devices, the quality of the PVA accounts for 10% of the total mass of the PVA and water; stage heating and stirring until the polyvinyl alcohol is completely dissolved , cooled to 25°C;

[0053] Step S220, weighing 8 parts of the PVA aqueous solution obtained in step S210, and adding them to the glue adjuster; weighing 30 parts of EVA rubber and 0.2 parts of borax, and adding them to the glue adjuster; stirring for 60 minutes to obtain a uniform product without particles;

[0054] Step S230, weighing 65 parts of EVA emulsion, adding to the glue adjuster; stirring for 60 minutes to obtain 2# packing glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com