Antibacterial synthetic resin, and preparation method thereof

A technology of synthetic resin and urea-formaldehyde resin, applied in the field of antibacterial synthetic resin and preparation thereof, can solve the problems of insufficient antibacterial properties of synthetic resin and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

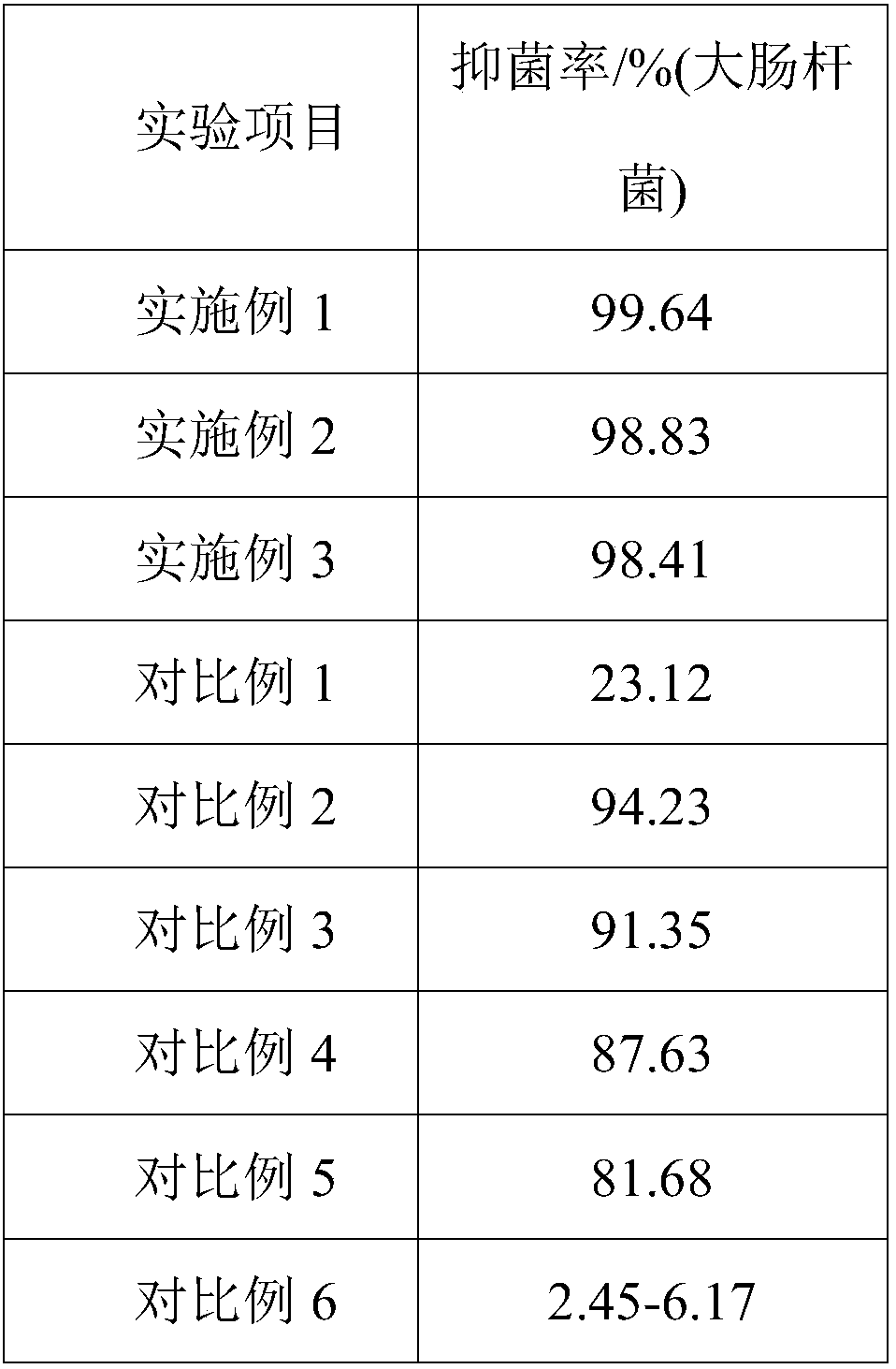

Examples

preparation example Construction

[0020] The preparation method of described antibacterial synthetic resin comprises the following steps:

[0021] S1. Mix polylactic acid, organic fluorine epoxy resin, polyphenylene sulfide and polycarbonate evenly in parts by weight, heat up to 80-90°C, keep warm for 20-40min, then add calcium molybdate, trimethyl phosphate, polycarbonate Mix caprolactone, fluorine micropowder, nano-montmorillonite, zinc borate, chlorinated paraffin and single-wall carbon nanotubes evenly, continue to heat up to 110-120°C, keep warm for 1-2h, and then stir at 1500-2500r / min for 30 -50min, cooled to room temperature to obtain the base material;

[0022] S2. Mix chitosan, zinc oxide, silane coupling agent KH-560 and antibacterial modification additive evenly, heat up to 80-90°C, keep warm for 10-20min, then stir at 650-850r / min for 10-20min , cooled to room temperature to obtain modified material;

[0023] S3. Raise the temperature of the base material to 80-90°C, keep it warm for 30-50 minut...

Embodiment 1

[0026] An antibacterial synthetic resin, in parts by weight, comprising the following raw materials: 50 parts of polylactic acid, 25 parts of organic fluorine epoxy resin, 10 parts of polyphenylene sulfide, 12 parts of polycarbonate, 6 parts of polyhydroxybutyrate, 6 parts of hydrogenated p-phenylenediamine, 4 parts of urea-formaldehyde resin, 3 parts of polypropylene resin, 4.5 parts of polyhydroxybutyrate, 4 parts of lauryl acrylate, 3 parts of calcium molybdate, 6 parts of trimethyl phosphate, polycaprolactone 6.5 parts of ester, 4 parts of fluorine powder, 3 parts of nano-montmorillonite, 4 parts of zinc borate, 6 parts of chlorinated paraffin, 6 parts of dispersant CNF, 3.5 parts of single-walled carbon nanotubes, 8 parts of chitosan, 10 parts of zinc oxide 5 parts, 5 parts of silane coupling agent KH-560, 15 parts of antibacterial modification auxiliary agent.

[0027] The antibacterial modification additive is prepared according to the following process: 10 parts by weigh...

Embodiment 2

[0033] An antibacterial synthetic resin, in parts by weight, comprising the following raw materials: 40 parts of polylactic acid, 35 parts of organic fluorine epoxy resin, 5 parts of polyphenylene sulfide, 16 parts of polycarbonate, 4 parts of polyhydroxybutyrate, 9 parts of hydrogenated p-phenylenediamine, 2 parts of urea-formaldehyde resin, 5 parts of polypropylene resin, 3 parts of polyhydroxybutyrate, 8 parts of lauryl acrylate, 1 part of calcium molybdate, 8 parts of trimethyl phosphate, polycaprolactone 3 parts of ester, 6 parts of fluorine powder, 1 part of nano-montmorillonite, 5 parts of zinc borate, 4 parts of chlorinated paraffin, 9 parts of dispersant CNF, 2 parts of single-walled carbon nanotubes, 10 parts of chitosan, 8 parts of zinc oxide 6 parts, 6 parts of silane coupling agent KH-560, 10 parts of antibacterial modification auxiliary agent.

[0034] The antibacterial modification additive is prepared according to the following process: 5 parts by weight of nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com