Prefabricated high-strength concrete pier as well as forming mold and manufacturing method of prefabricated high-strength concrete pier

A technology of high-strength concrete and bridge piers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

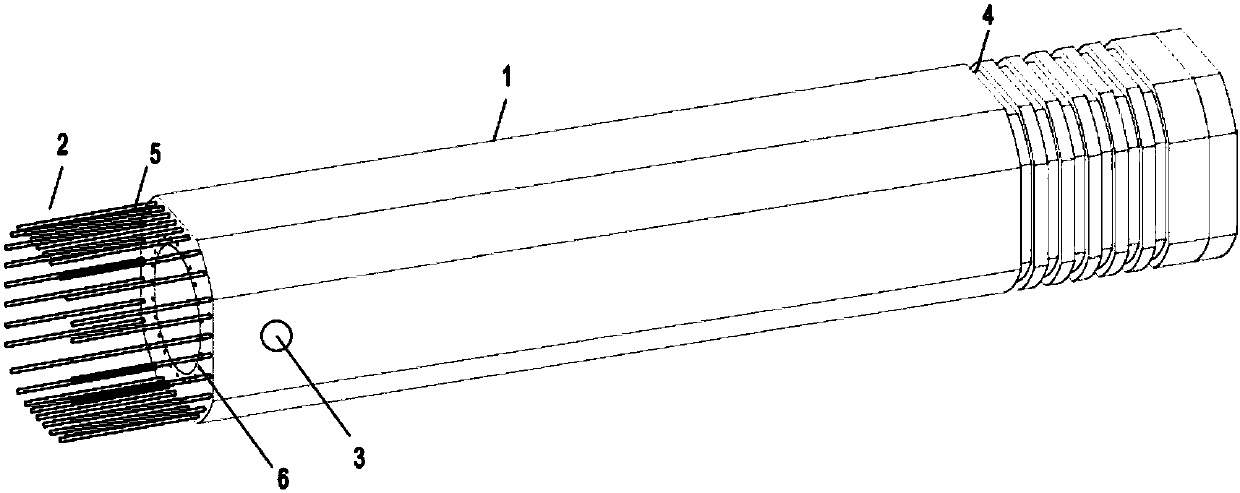

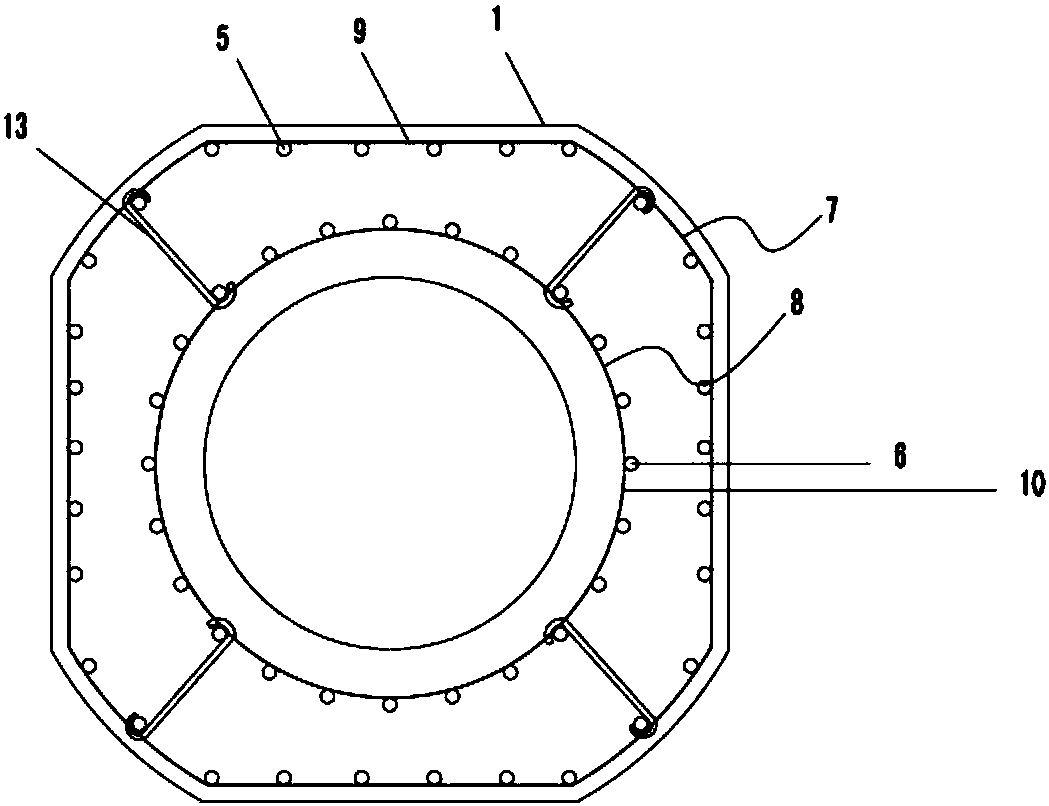

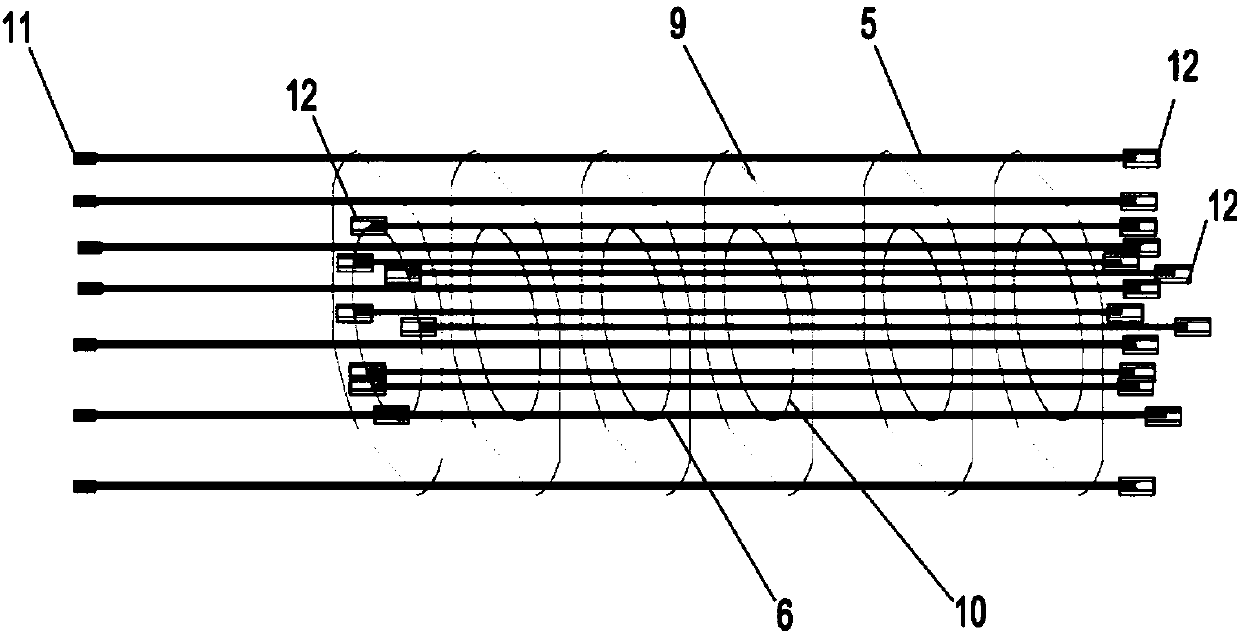

[0040] A kind of prefabricated high-strength concrete bridge pier of this embodiment, such as figure 1As shown, it includes pier body 1, steel frame cage 2 and hoisting hole 3. The pier body 1 is a full-length hollow structure. The cross-sectional shape of the pier body 1 is composed of four straight line segments and four arc segments. The arc segments are all on the same circumference, and the diameter of the circle is the length of the straight line segment. 1.5 to 2.5 times of that. Concave-convex groove segments 4 are arranged on the outer surface of the pier body 1 within 0.4 times of the pier length above the bottom end. The hoisting holes 3 are set within the range of 0.3 times the length of the pier body from the top of the pier, are arranged along the circumference of the pier body 1 and run through the pier body 1, and there are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thread length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com